Revolutionize Your Product Line with Carbon Nanoscale Fiber-Based Materials

Introduction

In an era where innovation drives success, the materials you choose can set you apart from the competition. Our patented “Carbon Nanoscale Fiber-Based Materials and Methods” (Patent #10586629) represents a leap forward in material science, offering unparalleled strength, conductivity, and versatility in a lightweight form.

The New Standard in Material Innovation

Imagine materials that are not only incredibly strong but also remarkably light, flexible, and electrically conductive. Carbon nanoscale fibers are at the forefront of this revolution, combining the extraordinary properties of carbon at the nanoscale to create materials that are stronger than steel, yet lighter than aluminum. These fibers can be woven, layered, and integrated into a variety of applications, opening up new possibilities across multiple industries.

Why This Matters to You

- Superior Strength and Lightweight Design: Carbon nanoscale fibers offer an exceptional strength-to-weight ratio, making them ideal for applications where reducing weight is critical without compromising durability. Whether you’re designing the next generation of aircraft, automotive components, or sports equipment, these materials allow you to push the boundaries of what’s possible.

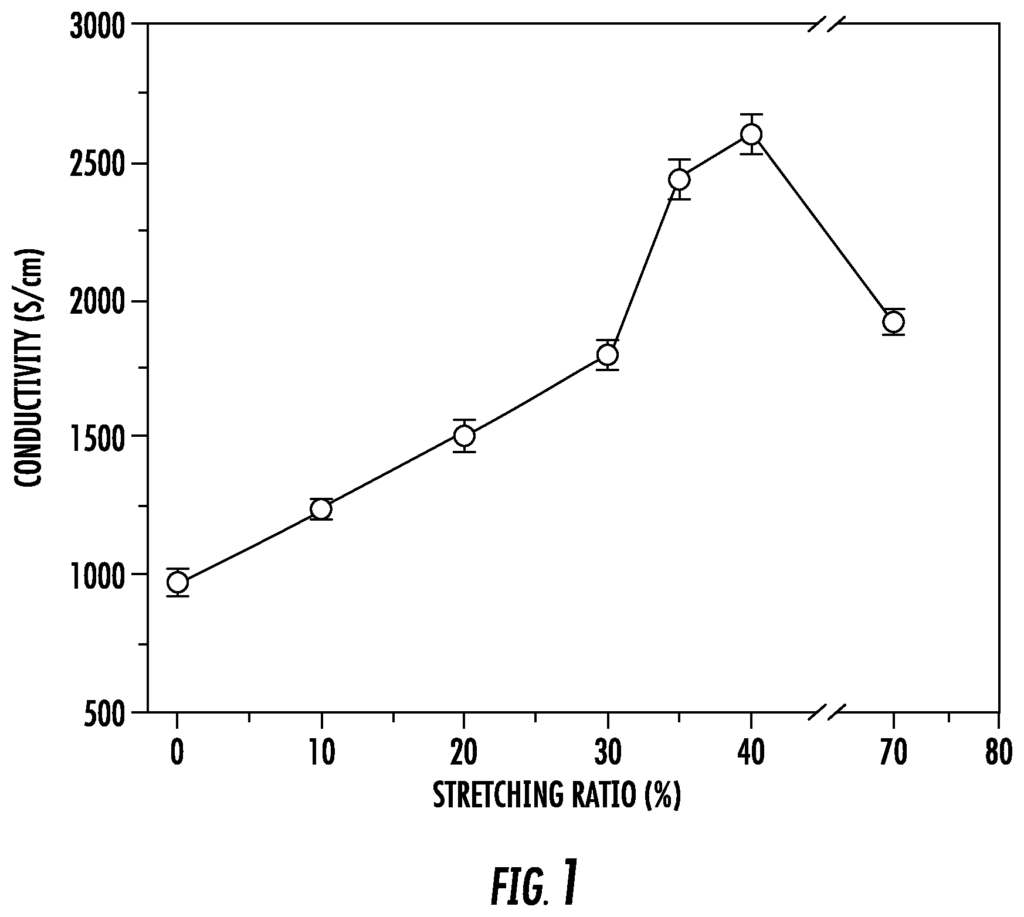

- Exceptional Electrical Conductivity: These fibers are not just strong—they’re also highly conductive. This makes them perfect for use in advanced electronics, energy storage solutions, and even smart textiles. Imagine the potential of integrating strong, flexible, and conductive materials into your products, creating smarter, more efficient designs.

- Versatile Applications Across Industries: The potential uses for carbon nanoscale fibers are vast. From aerospace and automotive to consumer electronics and medical devices, this technology offers a competitive edge in any industry that values innovation, performance, and cutting-edge materials.

- Future-Proof Your Products: As industries evolve, the demand for materials that can do more with less is only going to increase. By licensing this patent, you position your company at the forefront of material science, ready to meet the future’s challenges with solutions that are not only effective but also groundbreaking.

The Opportunity

This patent isn’t just about accessing a new material—it’s about redefining what your products can achieve. Carbon nanoscale fiber-based materials are the future of advanced manufacturing, offering the kind of performance that today’s consumers and industries are looking for. By licensing this technology, you’re not just keeping pace with innovation—you’re leading it.

Don’t let your competitors get ahead. License our carbon nanoscale fiber-based materials and methods today and start building the future of your industry, one fiber at a time.

- Abstract

- Claims

We claim:

1. A method of making a composite material, the method comprising:

14. A method of making a composite material, the method comprising:

Share

Title

Carbon nanoscale fiber-based materials and methods

Inventor(s)

Zhiyong Liang, Jin Gyu Park, Songlin Zhang, Ayou Hao

Assignee(s)

Florida State University Research Foundation Inc

Patent #

10586629

Patent Date

March 10, 2020