Empower Your Products with High-Performance Conductive Fiber Composites

Introduction

In a world where technology and materials are rapidly converging, the ability to innovate with cutting-edge materials can set your products apart. Our patented “Conductive Fiber Composites Containing Multi-Scale High Conductive Particles and Methods” (Patent #10828663) offers a breakthrough solution for industries looking to push the boundaries of what’s possible in conductivity and durability.

The Challenge

As electronic devices become more sophisticated and embedded in everything from clothing to cars, the demand for materials that combine flexibility, strength, and superior conductivity is skyrocketing. Traditional conductive materials often struggle with the trade-offs between performance and practicality—until now.

The Solution

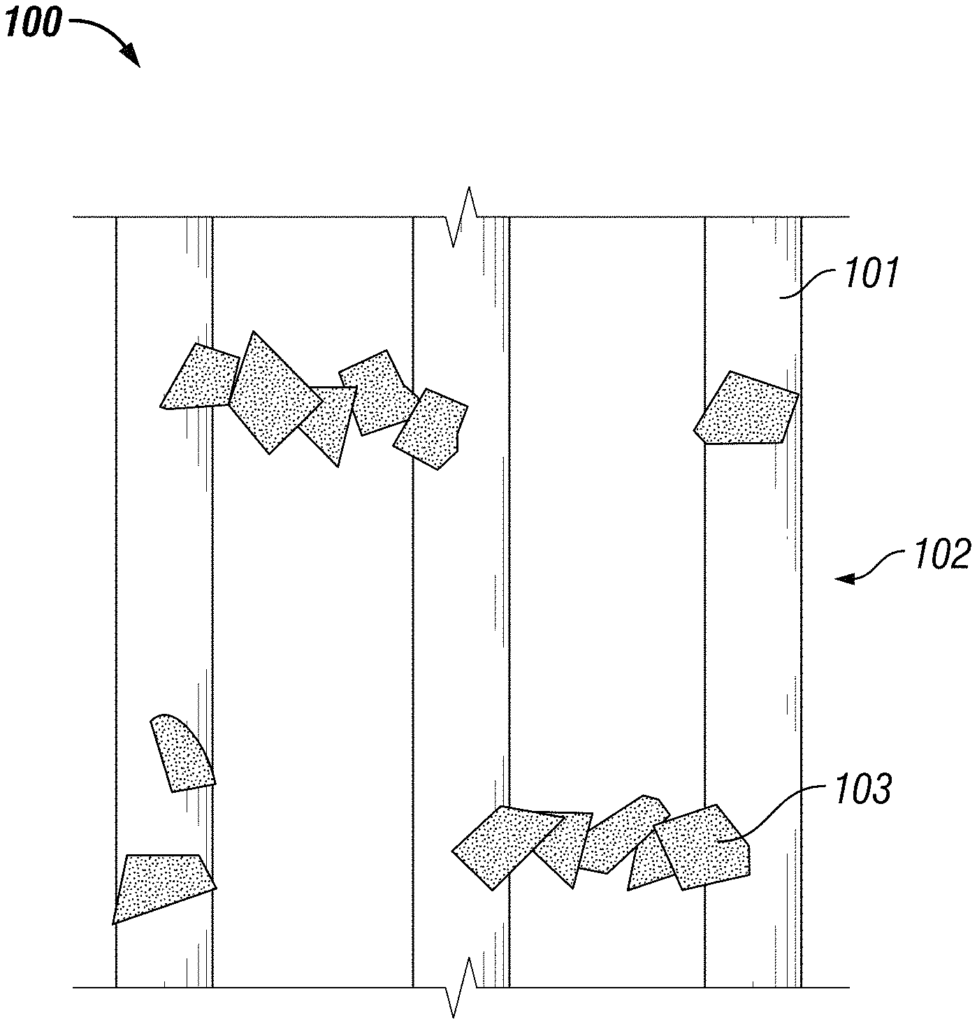

Our patented conductive fiber composite leverages multi-scale high conductive particles, creating a material that is not only highly conductive but also strong and adaptable. Imagine integrating this composite into your products, enabling them to perform better, last longer, and open new avenues of design and functionality.

Why License This Technology?

- Unmatched Conductivity: The multi-scale particles embedded in our fibers ensure that electricity flows efficiently, making this composite ideal for advanced electronics, smart textiles, and any application where reliable conductivity is crucial.

- Versatility Across Applications: Whether you’re in automotive, aerospace, consumer electronics, or fashion tech, this composite material can be tailored to meet the specific needs of your industry, allowing for innovative product designs that set you apart from the competition.

- Strength and Flexibility Combined: Unlike traditional conductive materials that may be brittle or limited in application, our composite offers the durability and flexibility you need to create products that are both high-performing and resilient.

The Opportunity

By licensing this patent, you’re not just adopting a material—you’re embracing a new standard in product innovation. Stay ahead of the curve and lead your industry with high-performance, conductive fiber composites that power the future.

- Abstract

- Claims

We claim:

1. A method for making a composite material, the method comprising:

9. A method for making a composite material, the method comprising:

Share

Title

Conductive fiber composites containing multi-scale high conductive particles and methods

Inventor(s)

Shaokai WANG, Zhiyong (Richard) Liang

Assignee(s)

Florida State University Research Foundation Inc

Patent #

10828663

Patent Date

November 10, 2020