High-Sensitivity Detection with Graphene-Based Nanosensors

Introduction

The demand for advanced sensor technologies that offer ultra-sensitive and rapid detection of target analytes is growing across industries. From healthcare diagnostics to environmental monitoring, the ability to identify specific compounds or biomarkers with precision can dramatically improve outcomes and drive innovation. Our patented graphene-based nanosensor presents a cutting-edge solution, offering high sensitivity and specificity for detecting a wide range of target analytes in real-time. This technology is set to transform how industries approach monitoring and diagnostics by providing faster, more accurate detection with minimal sample sizes.

Limitations in Conventional Sensor Technologies

Traditional sensor technologies often struggle with sensitivity, particularly when dealing with extremely low concentrations of target analytes. This poses significant challenges in critical applications like early disease detection, environmental contaminant monitoring, and pharmaceutical development, where even minute amounts of a compound can be crucial. Many conventional sensors also lack the speed or adaptability needed to keep up with real-time monitoring, leading to delays in diagnosis or decision-making.

These limitations highlight the need for more advanced sensor systems that can operate efficiently at the nanoscale, providing highly accurate detection with faster turnaround times. In industries like healthcare, where early detection of diseases can be life-saving, more sensitive and specific sensors are essential.

Graphene: The Key to Enhanced Sensitivity

Our patented graphene-based nanosensor takes full advantage of graphene’s unique properties—its extreme thinness, conductivity, and high surface area—to detect target analytes with unparalleled sensitivity. The nanosensor is designed to interact with specific analytes, such as biomarkers for diseases, pollutants, or chemical compounds, allowing it to provide a rapid and precise signal when the target is present.

The versatility of graphene allows this nanosensor to be adapted for a wide variety of applications, from medical diagnostics to environmental testing. In the healthcare field, for example, the nanosensor can be used to detect biomarkers of diseases like cancer at very early stages, enabling timely interventions. Similarly, in environmental monitoring, the sensor can detect pollutants or hazardous materials at ultra-low concentrations, providing a powerful tool for protecting ecosystems and public health.

Why This Technology Stands Out

- Unmatched Sensitivity: Graphene’s unique properties enable the sensor to detect even trace amounts of target analytes, ensuring high accuracy in critical applications.

- Fast, Real-Time Detection: The nanosensor provides rapid results, making it ideal for applications where time is of the essence, such as medical diagnostics or environmental monitoring.

- Wide Range of Applications: From healthcare to environmental science and consumer electronics, this technology can be adapted for numerous industries.

- Scalable and Cost-Effective: The nanosensor’s design allows for scalability in production, making it feasible for widespread commercial use.

Setting a New Standard for Nanosensor Technology

Licensing this graphene-based nanosensor technology offers a unique opportunity to develop highly sensitive, rapid, and adaptable detection systems across multiple industries. As the demand for real-time, high-precision monitoring continues to rise, this technology presents a transformative solution for businesses seeking to lead in biosensing, diagnostics, and environmental protection.

- Abstract

- Claims

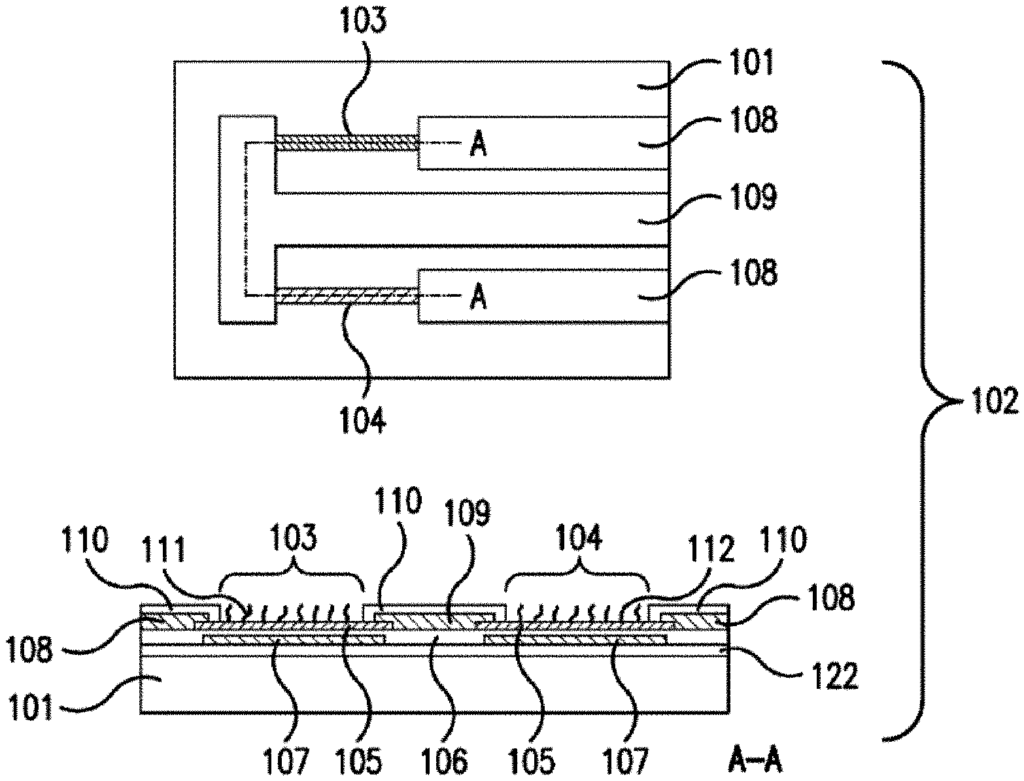

1. A microdevice for monitoring a target analyte, the microdevice comprising:

a field effect transistor comprising:

15. A method for monitoring a target analyte using an aptamer capable of binding to a target analyte, comprising:

Share

Title

Graphene-based nanosensor for identifying target analytes

Inventor(s)

Qiao Lin, Yibo Zhu, Junyi Shang, Zhixing Zhang, Xuejun Wang, Jaeyoung YANG, Cheng Wang, Pavana G. Rotti, John F. Engelhardt, Zhuang Hao

Assignee(s)

Department Of Anatomy And Cell Biology University Of Iowa, Columbia University in the City of New York

Patent #

20200196925

Patent Date

June 25, 2020