Cost-Effective Thin Film Silicon Production for Solar Energy Applications

Introduction

The growing demand for sustainable energy has increased the need for high-efficiency solar cells at a lower cost. Traditional methods of producing solar-grade silicon are energy-intensive and expensive, limiting the scalability of solar energy solutions. Our patented method of producing thin-film solar-grade silicon on metals by electrodeposition from silicon dioxide in molten salt offers a breakthrough in reducing manufacturing costs while maintaining high material quality. This innovative process provides a cost-effective way to produce thin-film silicon for solar applications, making it an attractive solution for the renewable energy market.

Limitations of Traditional Silicon Production

Current silicon production methods for solar panels involve high temperatures and complex processing, making the material expensive and the process energy-intensive. This directly impacts the cost of solar panels and limits the widespread adoption of solar energy systems. Additionally, the use of bulk silicon in traditional solar cells requires significant material consumption, which adds to production costs and limits efficiency in thin-film applications.

The challenge for manufacturers is to find a cost-effective method of producing high-purity silicon that can be easily deposited on metal substrates for solar cell applications, without sacrificing performance or durability.

An Innovative Electrodeposition Process for Thin-Film Solar Cells

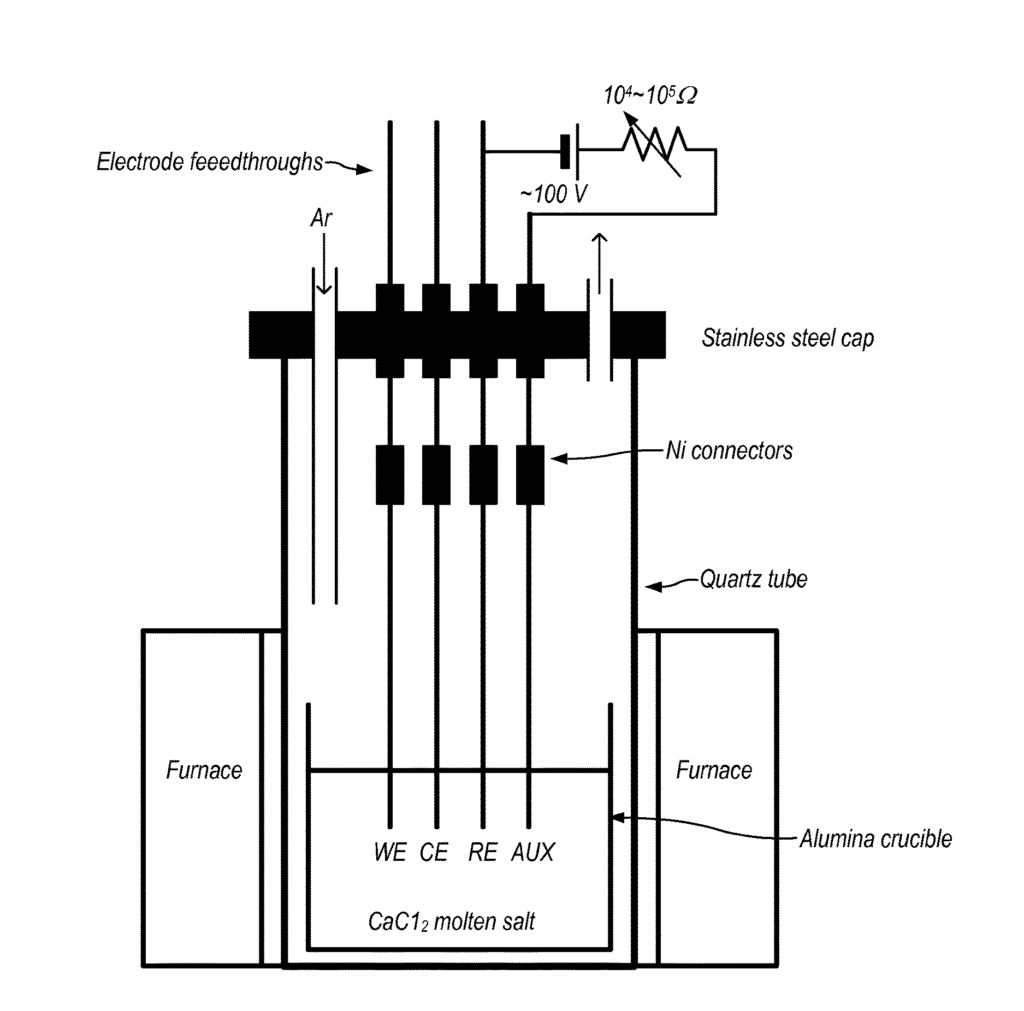

Our patented method offers a novel solution by using electrodeposition from silicon dioxide in a molten salt bath to produce thin-film solar-grade silicon directly onto metal substrates. This process operates at lower temperatures compared to conventional methods, significantly reducing energy consumption and overall production costs. Additionally, the electrodeposition process allows for precise control of the thin-film thickness, improving the efficiency and performance of the resulting solar cells.

This technology is particularly well-suited for large-scale solar panel manufacturing, where cost savings are crucial to making solar energy more competitive with traditional energy sources. Furthermore, the versatility of this process means it can be applied to a variety of metal substrates, making it adaptable to different manufacturing needs.

Key Benefits

- Lower Production Costs: Reduces energy consumption and material costs by using a molten salt electrodeposition process.

- High-Purity Thin Films: Produces solar-grade silicon with controlled thickness, improving the efficiency of thin-film solar cells.

- Scalability: Ideal for large-scale manufacturing, providing a cost-effective solution for expanding solar energy production.

- Versatile Application: Can be applied to various metal substrates, making it adaptable for different manufacturing setups.

Driving the Future of Affordable Solar Energy

Licensing this technology offers companies a unique opportunity to reduce the cost of solar-grade silicon production while improving the efficiency of thin-film solar cells. This method is a significant step forward in making solar energy more accessible and sustainable, positioning companies to lead in the growing renewable energy market.

- Abstract

- Claims

What is claimed is:

1. A method of producing a silicon film comprising:

14. A photovoltaic device comprising a silicon film on a silver substrate, wherein the silicon film is produced by the method comprising:

16. A method of producing a silicon film comprising:

Share

Title

Production of thin film solar grade silicon on metals by electrodeposition from silicon dioxide in a molten salt

Inventor(s)

Sung Ki Cho, Allen J. Bard, Fu-Ren F. Fan

Assignee(s)

University of Texas System

Patent #

10147842

Patent Date

December 4, 2018