Efficient Hydrogen Production Using Laser Ablation: A Green Energy Breakthrough

Introduction

As the world transitions toward cleaner energy sources, hydrogen is emerging as a key player in the race to develop sustainable, eco-friendly alternatives to fossil fuels. However, traditional hydrogen production methods often rely on processes that generate significant carbon emissions or require high energy inputs, limiting their environmental benefits. Our patented method of producing hydrogen through laser ablation offers a groundbreaking approach to hydrogen production, utilizing laser technology to generate hydrogen efficiently and sustainably. This advanced method paves the way for greener energy solutions while offering a versatile tool for industries looking to tap into hydrogen’s vast potential.

The Challenges of Traditional Hydrogen Production

While hydrogen is recognized as a clean energy carrier, most of the hydrogen produced today is derived from natural gas through a process called steam methane reforming, which emits large amounts of CO2. Alternatively, hydrogen can be produced through electrolysis, which requires significant energy input and remains relatively expensive to scale. As industries, governments, and environmental groups push for low-carbon alternatives, there is an increasing demand for more sustainable and cost-effective methods of producing hydrogen.

Achieving efficient hydrogen production without significant environmental impact is essential for industries such as transportation, manufacturing, and energy storage, where hydrogen’s potential is vast but underutilized due to production limitations.

A Clean, Laser-Based Hydrogen Production Method

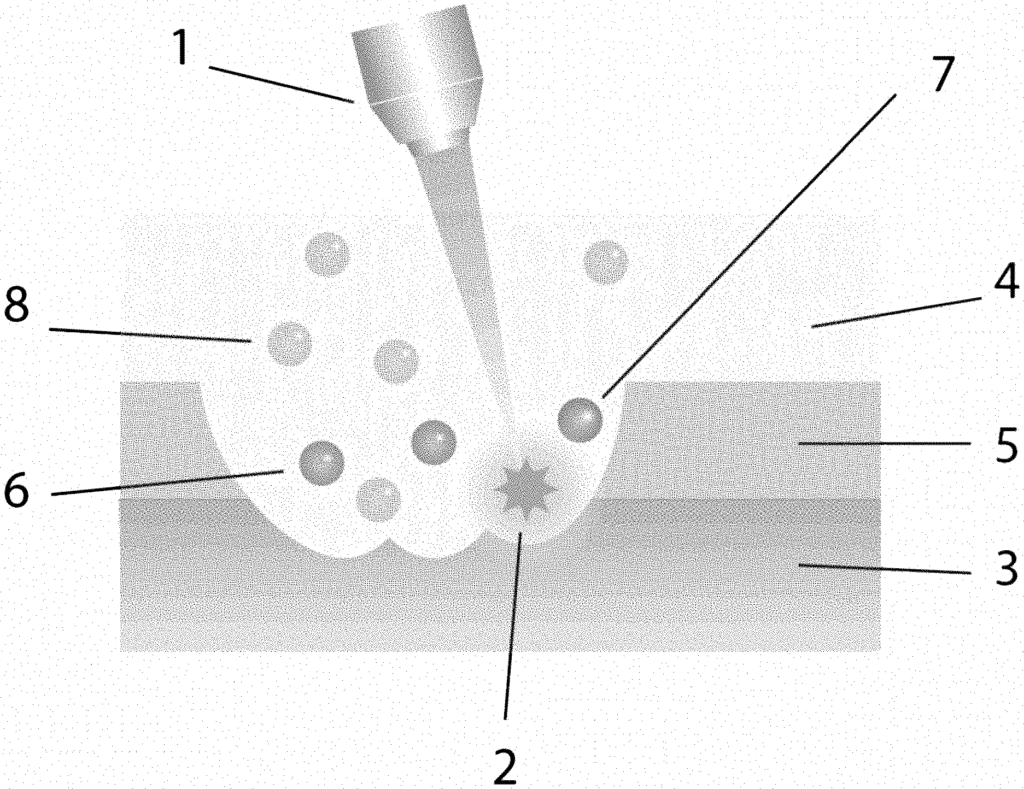

Our method of producing hydrogen through laser ablation provides an innovative solution to these challenges. By utilizing laser technology to ablate materials such as water or other hydrogen-containing compounds, the process generates pure hydrogen without relying on carbon-emitting fossil fuels or expensive, energy-intensive methods. Laser ablation involves the use of high-energy laser pulses to break molecular bonds and release hydrogen, allowing for clean, efficient hydrogen production with minimal waste and energy input.

This technology offers flexibility, as it can be applied to various materials and can be scaled to meet the needs of industries ranging from small-scale hydrogen generation to large-scale production. Its versatility and environmental benefits make it an attractive solution for companies aiming to reduce their carbon footprint while tapping into the growing hydrogen economy.

Key Benefits

- Sustainable Hydrogen Production: Generates hydrogen without relying on carbon-emitting methods or fossil fuels.

- Energy Efficient: Uses laser ablation to produce hydrogen with lower energy input compared to traditional methods.

- Scalable Technology: Suitable for both small-scale and industrial hydrogen production, adaptable to different applications.

- Green Energy Focus: Provides a clean alternative for industries looking to integrate hydrogen into their energy strategies.

Driving the Future of Hydrogen Energy with Advanced Laser Technology

Licensing this laser ablation-based hydrogen production method offers companies in the energy and clean technology sectors a groundbreaking tool for generating hydrogen efficiently and sustainably. By embracing this innovative approach, businesses can lead the charge in the green energy movement, ensuring a cleaner, more sustainable future powered by hydrogen.

- Abstract

- Claims

The invention claimed is:

1. A method, comprising:

6. The method of claim 1, further comprising:

8. The method of claim 1, further comprising:

13. The method of claim 1, further comprising:

15. The method of claim 1, further comprising:

16. The method of claim 1, wherein:

17. The method of claim 16, wherein:

18. The method of claim 1, wherein:

Share

Title

Method of producing hydrogen through laser ablation

Inventor(s)

Vladlen G. Shvedov

Assignee(s)

New World Energy LLC

Patent #

10899611

Patent Date

January 26, 2021