Precision and Versatility with Multi-Blade Handle System

Introduction

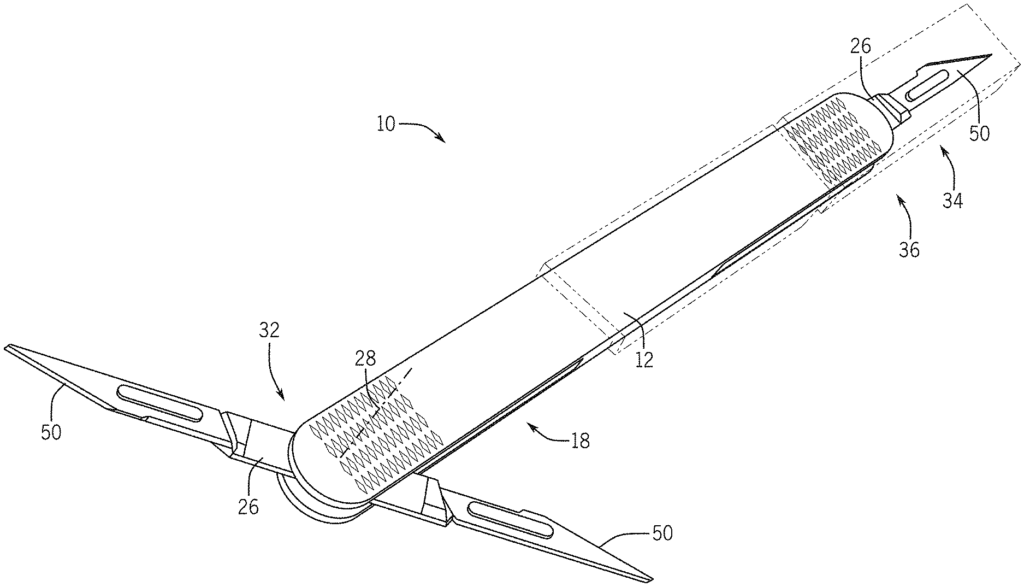

This innovative multiple blade handle system offers unmatched versatility and precision, making it an essential tool for industries ranging from home improvement to medical devices. Designed to accommodate multiple blade types, this system allows users to switch between blades quickly and efficiently without sacrificing accuracy or control. Whether in construction, DIY projects, or even surgical applications, this multi-blade system provides a streamlined approach to tool use, reducing the need for multiple handles and enhancing user productivity.

The Challenge: Tool Flexibility and Efficiency

In many professional and consumer applications, the need for multiple blades can often mean carrying several tools, leading to inefficiencies and added costs. Traditional tool systems require separate handles for each blade type, creating clutter and slowing down processes as users switch between tools. This lack of flexibility affects not only productivity but also safety, as managing multiple tools increases the risk of errors or accidents. Finding a tool system that can support multiple blades while maintaining the necessary precision and ease of use is a growing demand across various industries.

Multi-Blade System for Seamless Operation

This multi-blade handle system addresses these challenges by offering a single handle that securely accommodates multiple blade types, allowing for seamless transitions between tasks. The system is engineered for stability and ease of use, ensuring that each blade remains securely in place during operation while providing the user with the control and accuracy needed for detailed work. Whether cutting, scraping, or performing other tasks, users can rely on this system to maintain precision and functionality across different blade configurations.

Key Advantages Across Sectors

For hand tool manufacturers, this technology offers a way to enhance product lines with a versatile system that reduces the need for multiple tools, providing greater value to customers. Medical device companies can benefit from its precision and adaptability, applying it in surgical tools where quick blade changes and stability are essential. In the home improvement and DIY markets, this system simplifies toolkits by reducing the number of handles needed while improving user convenience and workflow. Industrial equipment manufacturers will also find value in the system’s durability and flexibility, particularly in environments where different blade types are frequently required.

Invest in Tool Innovation and Flexibility

Licensing this multi-blade handle system gives your organization a strategic advantage in delivering tools that meet modern demands for versatility, precision, and efficiency. With a focus on adaptability, this system empowers users to switch between tasks quickly and safely, enhancing productivity while reducing tool clutter. It’s an ideal solution for industries where precision and convenience matter, providing a next-level tool experience that simplifies operations and supports greater control.

- Abstract

- Claims

The invention claimed is:

1. A multiple blade handle system, comprising:

2. The multiple blade handle system of claim 1, wherein the body further comprises:

4. The multiple blade handle system of claim 1, further comprising:

7. The multiple blade handle system of claim 1, further comprising:

9. A multiple blade handle system, comprising:

10. The multiple blade handle system of claim 9, further comprising:

11. The multiple blade handle system of claim 9, further comprising:

12. The multiple blade handle system of claim 9, further comprising:

13. The multiple blade handle system of claim 9,

15. The multiple blade handle system of claim 9, further comprising:

Share

Title

Multiple blade handle system

Inventor(s)

Deidre Quinn-Gorham, Sharanabasaweshwara Asundi, Jimesh Bhagatji

Assignee(s)

Tuskegee University

Patent #

11013529

Patent Date

May 25, 2021