Manufacturing of Superluminescent Light-Emitting Diodes with a Ternary Halide Perovskite/Polymer Composites

Introduction

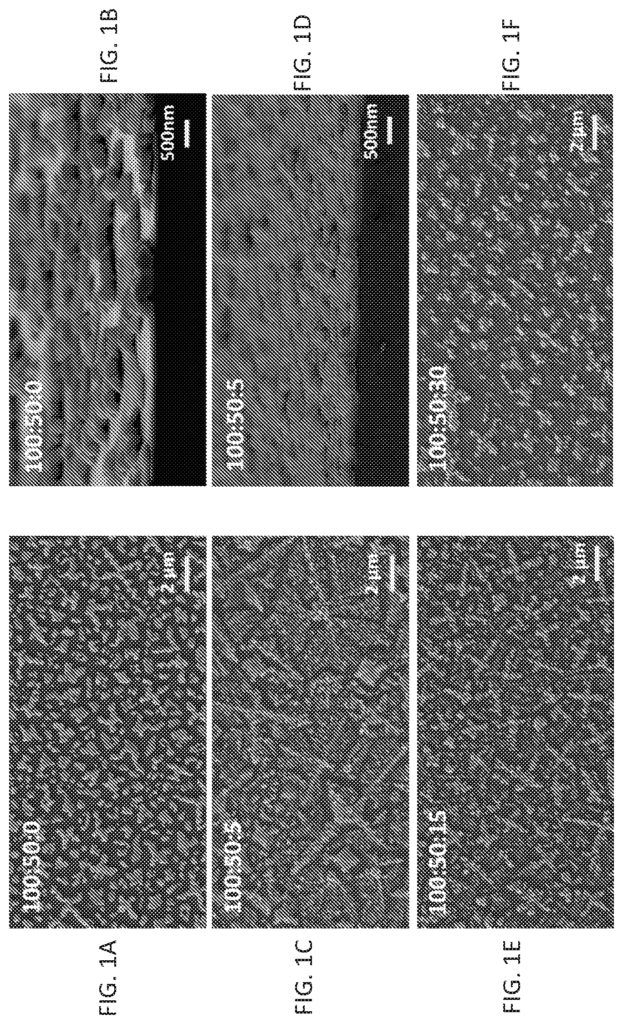

Halide perovskites have emerged as a new generation semiconducting materials for LED applications. A recent finding at the Flroida State University found by adding an ionic insulating polymer into the mixture of perovskite/ionic-conducting polymer the device can perform significantly better. The use of a ternary composite to replace the previously used binary composite can help optimize the morphology and crystallinity of the perovskite materials, which led to efficient charge injection and transportation in the composites.

This invention allows LEDs to achieve a reach of 800,000 cd m-2, 40x higher than the previous record. These devices can also be switched on at 1.8V, 40 percent lower than the devices with a binary composite.

- Abstract

- Claims

An emissive perovskite ternary composite thin film comprising a perovskite material, an ionic-conducting polymer and an ionic-insulating polymer is provided. Additionally, a single-layer LEDs is described using a composite thin film of organometal halide perovskite (Pero), an ionic-conducting polymer (ICP) and an ionic-insulating polymer (IIP). The LEDs with Pero-ICP-IIP composite thin films exhibit a low turn-on voltage of about 1.9V (defined at 1 cd m−2 luminance) and a luminance of about 600,000 cd m−2.

What is claimed is:

1. A method for manufacturing a single-layer optoelectronic device, the method comprising:

Share

Title

SUPERLUMINESCENT HALIDE PEROVSKITE LIGHT - EMITTING DIODES WITH A SUB - BANDGAP TURN - ON VOLTAGE

Inventor(s)

Zhibin Yu, Junqiang Li, Xin Shan

Assignee(s)

Florida State University Research Foundation Inc

Patent #

20200295275

Patent Date

September 17, 2020