Deterministic Nucleation for Halide Perovskite Thin Films with Large and Uniform Grains

Introduction

In recent years, remarkable optoelectronic properties have been discovered in a group of halide perovskite semiconductors. Their potential to invigorate the current solar cell and light-emitting diode (LED) industries has been demonstrated by achieving very high device efficiencies in relatively short periods. While higher efficiency records are pursued, an equally important task is to improve their device reliability. So far, most reported perovskite solar cells and LEDs employed a polycrystalline thin film for light absorbing or light emitting purposes. The size of the grains in such films typically varied from sub-100 nanometers to a few micrometers. The high density of grain boundary defects can trap charge carriers and aid the diffusion of water molecules and ionic species in the perovskites, deteriorating their structural integrity and transportation properties in long-term applications.

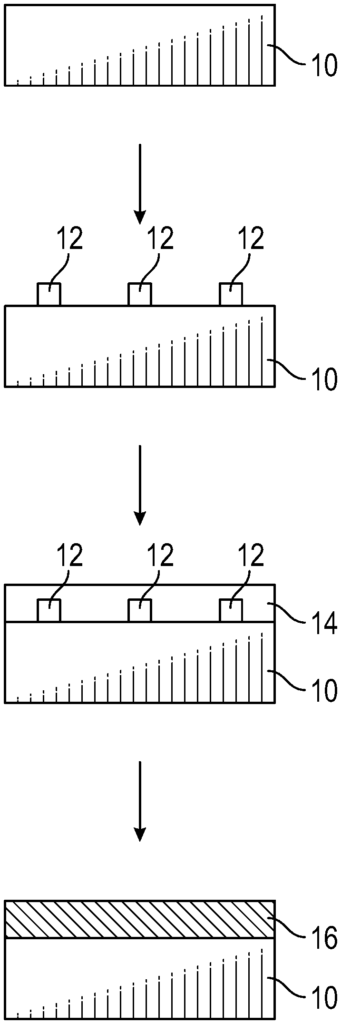

We recently have invented a new process enabling the formation of perovskite thin films with a ultra-large and uniform grain size. The large grain size will significantly reduce the density of grain boundaries, and the films perform nearly the same as single crystalline materials. In addition, the simple solution process in our approach will potentially more practical to scaled up for future high throughput industrial production. The new discovery is based on our scientific understanding to precisely control the nucleation sites and nucleation densities of halide perovskites during film formation on a substrate.

Our halide perovskite thin films with large and uniform grains can exhibit enhanced structural and morphological stability in ambient air. For instance, efficient LEDs had been made with our methylammonium lead tribromide films after exposing them in air for three months without encapsulation. Our halide perovskite thin films also showed greatly reduced ionic migration tendency under an external electrical field. Photo-detectors had been fabricated using our methylammonium lead triiodide films. The devices exhibited 10 times lower dark current at a constant applied voltage compared to devices with conventional halide perovskite thin films that were processed using previously reported methods. In addition, no measurement hysteresis was observed in our halide perovskite thin films when a dynamic voltage was applied at both dark and illuminated conditions.

- Abstract

- Claims

Methods are provided for making halide perovskite thin films . The method may include forming a pattern of islands of a nucleation promoter material onto a substrate ; applying onto the substrate and islands a solution which includes a halide perovskite or pre – cursors thereof , to form a coated substrate ; and drying the coated substrate to form a crystal line halide perovskite film . Halide perovskite thin films , which may be made by these methods , and LEDs including these films are also provided.

1. A method of making a halide perovskite thin film comprising:

12. A halide perovskite thin film structure comprising:

21. An LED comprising:

Share

Title

HALIDE PEROVSKITE THIN FILMS AND METHODS FOR PRODUCTION THEREOF

Inventor(s)

Zhibin YU, Thomas GESKE

Assignee(s)

Florida State University Research Foundation Inc

Patent #

11349091

Patent Date

April 9, 2020