Introduction

Are you looking to enhance the efficiency and reliability of your centrifugal compressors? We offer a cutting-edge solution to one of the most critical challenges in compressor technology: surge prevention.

This innovative system uses precise microjet injection to actively control surge conditions, significantly reducing the risk of compressor downtime and extending equipment lifespan. By licensing this technology, you can:

-

- Boost Efficiency: Optimize compressor performance, resulting in lower energy consumption and operational costs.

-

- Enhance Reliability: Prevent costly failures and maintain smooth operations with advanced surge control.

-

- Expand Applications: Ideal for use in industries like oil and gas, aerospace, power generation, and manufacturing.

Don’t miss the opportunity to integrate this state-of-the-art technology into your compressors, ensuring top-tier performance and reliability. License our surge control system today and stay ahead in the competitive industrial landscape.

- Abstract

- Claims

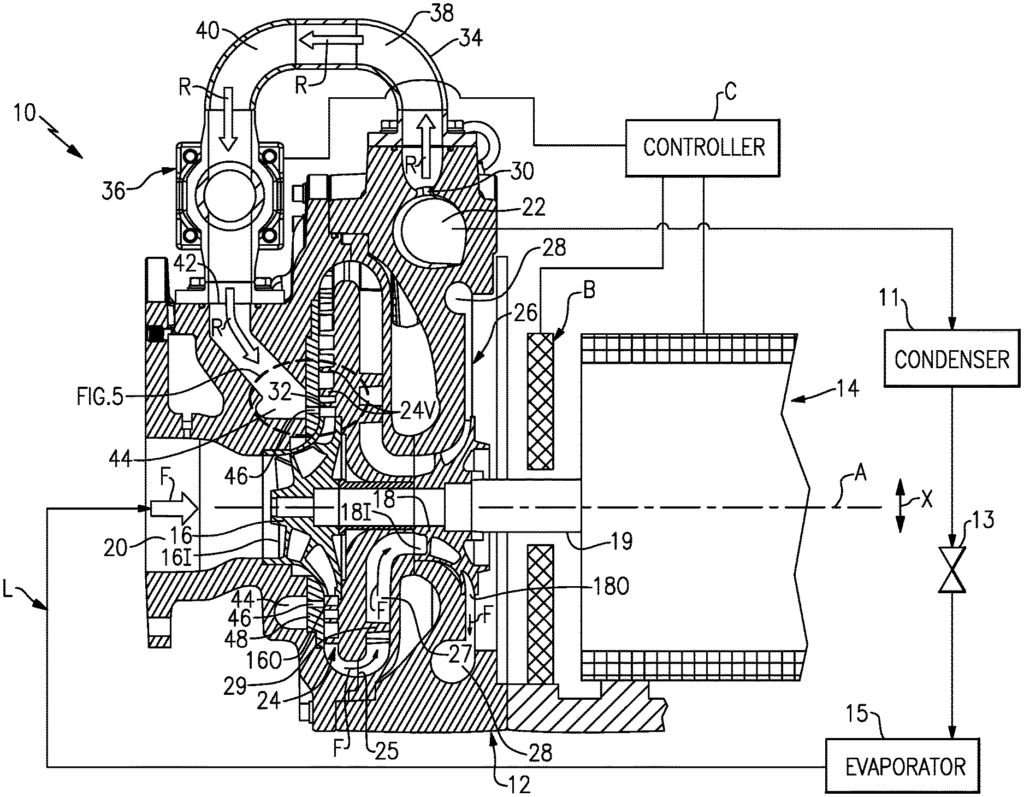

A centrifugal compressor according to an exemplary aspect of the present disclosure includes , among other things , an impeller provided in a main flow path and configured to pressurize a main flow of fluid . The compressor also includes a secondary flow path configured to provide a secondary flow by recirculating a portion of the main flow . The amount of the main flow that becomes the secondary flow is less than or equal to 15 % . A method is also disclosed.

What is claimed is:

1. A centrifugal compressor, comprising:

13. The compressor as recited in claim 1, further including:

14. A centrifugal compressor, comprising:

16. A method of operating a centrifugal compressor, comprising:

Share

Title

Active surge control in centrifugal compressors using microjet injection

Inventor(s)

Joost Brasz, William Bilbow, Farrukh ALVI, Erik Fernandez, Jennifer Gavin

Assignee(s)

Danfoss AS, Florida State University Research Foundation Inc

Patent #

10962016

Patent Date

March 30, 2021