Achieve Stability with Advanced Gelling Nanofluids

Introduction

The potential of nanofluids in modern industries—ranging from energy production to pharmaceuticals—has been widely recognized. However, one of the biggest challenges these fluids face is dispersion stability. Our patented gelling nanofluid technology offers a transformative solution to ensure that nanoparticles stay evenly distributed, enhancing both performance and reliability in various applications. Whether for industrial fluids, drilling, or drug delivery, this advanced gelling nanofluid technology brings innovation, stability, and long-lasting effectiveness.

Challenges in Nanofluid Dispersion Stability

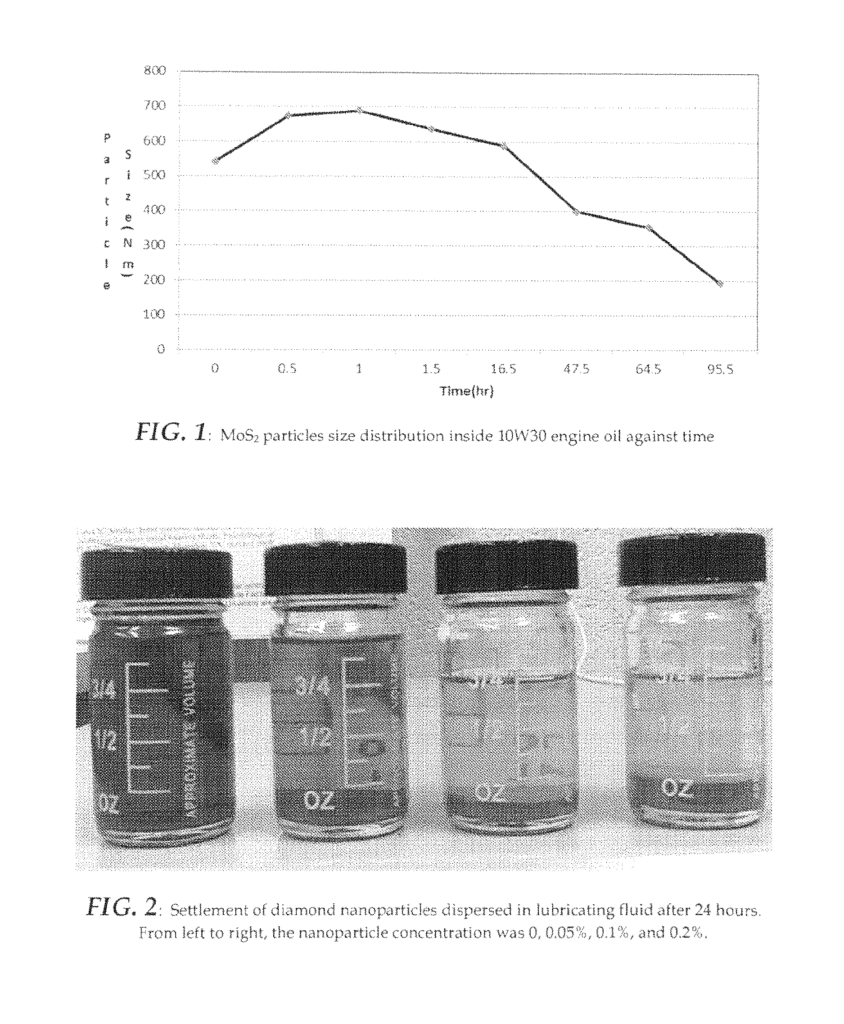

Nanofluids, which are suspensions of nanoparticles in liquids, offer many advantages in terms of heat transfer, lubrication, and functionality in industries such as oil and gas, pharmaceuticals, and manufacturing. However, maintaining the stable dispersion of nanoparticles is a major challenge. Over time, particles tend to aggregate or settle, reducing the effectiveness of the nanofluid and leading to inconsistent performance.

For industries that rely on nanofluids, ensuring stable dispersion is crucial to maintaining the integrity and performance of the product. Without a reliable solution, companies face increased costs, product waste, and diminished effectiveness.

Why Choose Advanced Gelling Nanofluids?

Our patented gelling nanofluid technology provides a robust answer to the challenge of dispersion stability. By creating a gel-like matrix within the fluid, the technology ensures that nanoparticles remain uniformly suspended for extended periods. This results in more consistent fluid behavior, improving efficiency and reliability across a range of applications.

In the oil and gas industry, for example, stable nanofluids can be used to enhance drilling performance and increase efficiency in extraction processes. In pharmaceuticals, stable nanofluids provide a reliable means of drug delivery, ensuring that therapeutic nanoparticles remain suspended and functional. Across all sectors, the use of advanced gelling nanofluids leads to better outcomes, reduced waste, and lower overall costs.

Key Benefits

- Enhanced Stability: Prevents nanoparticle aggregation and settling, ensuring long-term suspension.

- Improved Efficiency: Consistent fluid behavior leads to more effective processes in oil and gas, pharmaceuticals, and manufacturing.

- Versatile Applications: Suitable for a wide range of industrial and pharmaceutical uses.

- Cost-Effective: Reduces product waste and improves the performance of nanofluids, lowering overall costs.

Achieve Consistency with Advanced Gelling Nanofluids

Licensing this advanced gelling nanofluid technology provides industries with a powerful tool to enhance stability, performance, and cost-effectiveness in their applications. From energy production to drug delivery, this technology ensures that nanofluids remain stable and efficient, empowering industries to maximize their potential.

- Abstract

- Claims

What is claimed is:

1. A nanofluid comprising:

2. A nanofluid comprising:

5. A nanofluid comprising:

9. A method of preparing a gelling nanofluid, the method comprising the steps of:

16. A method of preparing a gelling nanofluid, the method comprising the steps of:

Share

Title

Gelling nanofluids for dispersion stability

Inventor(s)

Mohsen Mosleh, Mohammad Ghaderi-Yeganeh

Assignee(s)

Howard University

Patent #

9840679

Patent Date

December 12, 2017