Extend Component Life with Anti-Wear Solutions

Introduction

In industries where machinery and equipment are pushed to their limits, wear and tear on critical components can lead to costly repairs, reduced efficiency, and shorter lifespans. Whether in the automotive, aerospace, or manufacturing sectors, finding effective methods to reduce surface wear is essential for improving performance and minimizing downtime. Our patented methods and compositions for reducing surface wear offer a groundbreaking solution, allowing companies to extend the life of their equipment, enhance performance, and reduce maintenance costs.

The Ongoing Challenge of Surface Wear

Surface wear is a persistent issue in industries that rely on mechanical systems and moving parts. Friction between surfaces leads to degradation over time, resulting in the need for frequent repairs or replacements. Traditional methods for reducing wear—such as using lubricants or modifying surface materials—offer some relief but often fall short of providing long-lasting solutions.

Without effective wear prevention, companies face high maintenance costs, operational delays, and decreased overall efficiency. The need for reliable, long-term wear reduction methods is critical for ensuring that machinery and systems continue to perform at their best.

Why Choose Anti-Wear Solutions?

Our anti-wear technology provides a powerful solution for industries looking to reduce surface friction and extend the lifespan of their components. By applying advanced compositions and methods to minimize wear, this technology ensures that surfaces in contact with each other experience less degradation over time. This leads to longer-lasting machinery, reduced maintenance requirements, and significant cost savings.

The versatility of this solution allows it to be used across a wide range of applications, from automotive engines and aerospace systems to industrial manufacturing equipment. Whether protecting gears, bearings, or other moving parts, the anti-wear composition ensures smooth operation and enhanced durability. By licensing this technology, companies can dramatically improve the performance and longevity of their critical systems.

Key Benefits

- Reduced Wear: Minimizes surface degradation, extending component life.

- Enhanced Durability: Improves the lifespan of machinery, reducing the need for frequent repairs.

- Cost Savings: Lowers maintenance costs by reducing wear-related damage.

- Broad Applications: Suitable for automotive, aerospace, and industrial equipment.

Unlock Greater Durability with Anti-Wear Solutions

Licensing this anti-wear technology provides companies with a powerful tool to protect their investments, extend equipment life, and improve operational efficiency. By reducing wear, businesses can minimize downtime, boost performance, and cut long-term maintenance costs.

- Abstract

- Claims

What is claimed is:

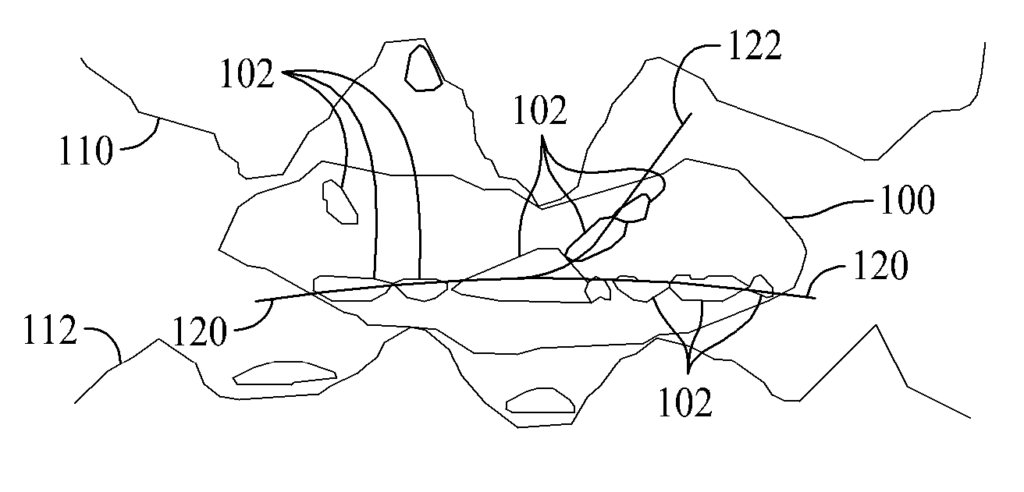

1. A method for reducing wear between two surfaces in at least one of sliding or rolling contact with one another, with relative motion between the two surfaces, said method comprising:

2. The method according to claim 1 wherein introducing nanoparticles comprises at least one of:

11. A method for reducing wear of two surfaces in sliding contact with one another, said method comprising:

Share

Title

Methods and compositions for reducing wear of surfaces in contact with one another

Inventor(s)

Mohsen Mosleh, John H. Belk

Assignee(s)

Howard University, Boeing Co

Patent #

9605228

Patent Date

March 28, 2017