Durable and Adaptive Resilient Foams for Innovation

Introduction

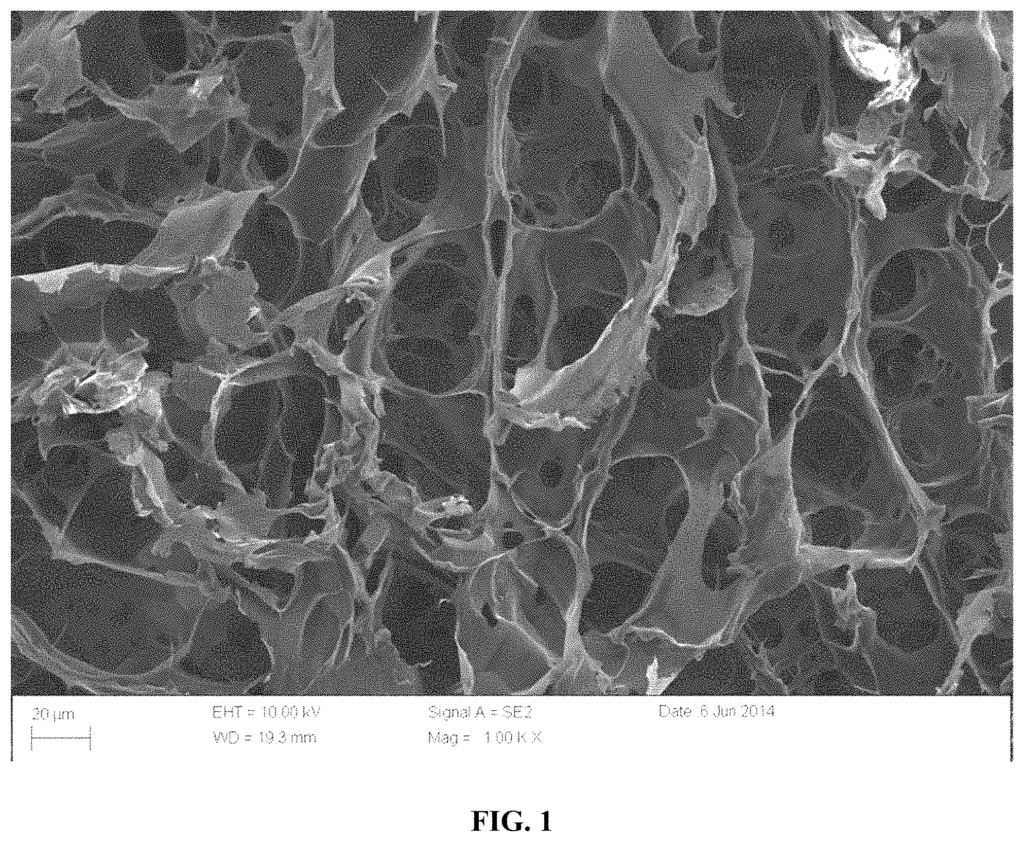

This resilient foam technology offers a groundbreaking material solution for industries requiring durable, flexible, and adaptive foams that perform consistently under pressure. With unique structural properties, this foam delivers high resilience and energy absorption, making it perfect for applications in manufacturing, automotive, aerospace, packaging, and even medical devices. For companies seeking advanced material solutions to improve product performance and sustainability, this technology provides the versatility and durability needed to meet evolving market demands.

The Challenge: Meeting the Growing Demand for Resilient Materials

Many industries rely on resilient foams for a variety of applications, from cushioning and insulation to impact protection and medical uses. However, traditional foam materials often struggle to maintain their structural integrity and performance over time, particularly in high-stress or repetitive use environments. Companies are facing growing pressure to deliver products that are not only more durable but also environmentally friendly and adaptable to diverse applications. As industries evolve, the demand for advanced foam materials that balance durability with flexibility continues to rise.

Resilient Foam for Versatile and Sustainable Applications

This resilient foam technology addresses these challenges by providing a material that retains its shape, flexibility, and strength even after repeated use. It offers exceptional energy absorption, impact resistance, and cushioning, making it ideal for use in high-performance applications. Whether it’s used for automotive seating, aerospace insulation, packaging protection, or medical cushioning, this foam adapts to various needs while maintaining durability and comfort. Additionally, the foam’s adaptability allows it to be applied across different industries with minimal customization, providing a highly versatile material solution.

Key Benefits for Multiple Industries

In the automotive and aerospace sectors, this foam provides superior cushioning and impact absorption, ensuring passenger safety and comfort while reducing weight and fuel consumption. Packaging companies can use the foam to protect fragile goods during transport, offering enhanced shock resistance. Medical device manufacturers will benefit from its cushioning properties for wound care, orthopedic products, and other health-related applications. The foam’s ability to maintain its resilience and structure also makes it an ideal choice for consumer goods, where durability and comfort are essential.

Invest in Future-Proof Foam Technology

Licensing this durable resilient foam technology positions your company to lead in material innovation across multiple industries. By offering a foam that combines flexibility, strength, and adaptability, your business can meet the rising demand for high-performance materials in sectors ranging from automotive to healthcare. This technology represents an investment in sustainability and product longevity, providing a material that can withstand the rigors of modern applications while improving comfort, safety, and efficiency.

- Abstract

- Claims

The invention claimed is:

1. A method of preparing a resilient foam, the method comprising:

Share

Title

Resilient foams and uses thereof

Inventor(s)

George T. Delli-Santi, Helawe Betre

Assignee(s)

Smith and Nephew Inc

Patent #

10800905

Patent Date

October 13, 2020