Eco-Friendly Strength with Green Resin Innovation

Introduction

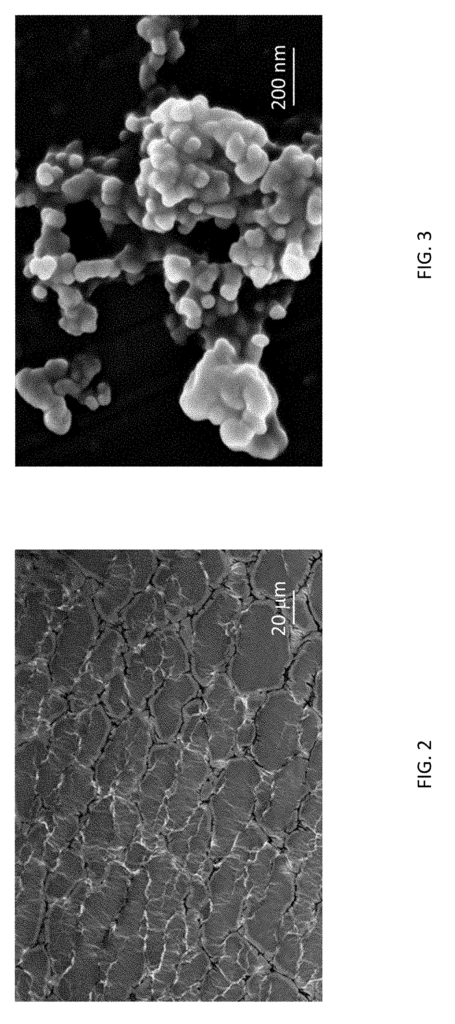

As industries strive to meet sustainability goals, the need for eco-friendly materials has never been more important. Traditional epoxy resins, widely used in construction, manufacturing, and coatings, are typically derived from petrochemical sources, making them environmentally unsustainable. Our patented green epoxy resin, made with a biobinder from manure, offers a breakthrough solution by providing a sustainable alternative that doesn’t compromise on strength or durability.

Challenges with Conventional Resins

Epoxy resins are vital in numerous industries, providing strong, durable coatings, adhesives, and structural materials. However, the petrochemical base of most resins contributes to environmental issues, including non-biodegradability and reliance on finite resources. Furthermore, the production process often emits harmful chemicals and increases carbon footprints, making traditional epoxy resins incompatible with today’s focus on green manufacturing and sustainability.

As industries face increasing pressure to reduce their environmental impact, there is a growing need for materials that perform just as well as their conventional counterparts while being eco-friendly. This is where green resin technology comes into play, offering a way to meet sustainability demands without sacrificing performance.

The Benefits of Green Resin Innovation

Our patented green epoxy resin provides the perfect solution by using a biobinder derived from manure, transforming waste into a valuable resource. This innovative resin offers high-strength, durability, and versatility, making it suitable for a wide range of applications in construction, manufacturing, and product development. Its biodegradable nature reduces the environmental impact of its disposal, making it an ideal choice for companies committed to sustainability.

The production process is also more environmentally friendly, utilizing renewable resources and reducing reliance on petrochemicals. This makes the green resin not only a better choice for the environment but also a cost-effective alternative for industries looking to lower their carbon footprint and adhere to stricter environmental regulations.

Key Benefits

- Eco-Friendly: Made from renewable resources, significantly reducing environmental impact.

- Biodegradable: Offers a sustainable option for disposal, minimizing waste.

- Strong and Durable: Performs as well as conventional resins, ideal for industrial applications.

- Versatile Applications: Suitable for construction, manufacturing, and product development.

Innovate Sustainably with Green Resin Innovation

Licensing this green resin technology offers a unique opportunity to embrace sustainability in construction, manufacturing, and other industries. With its powerful combination of eco-friendliness, strength, and cost-effectiveness, this green epoxy resin is set to drive the future of sustainable material innovation.

- Abstract

- Claims

What is claimed is:

1. A curable epoxy resin composition comprising:

9. A kit for providing the curable epoxy resin composition of claim 1, wherein the kit comprises:

15. The method of claim 11, further comprising:

17. A prepreg comprising:

Share

Title

Green epoxy resin with biobinder from manure

Inventor(s)

Lifeng Zhang, Elham H. Fini, Sidharth Reddy Karnati

Assignee(s)

North Carolina A&T State University

Patent #

20190233638

Patent Date

August 1, 2019