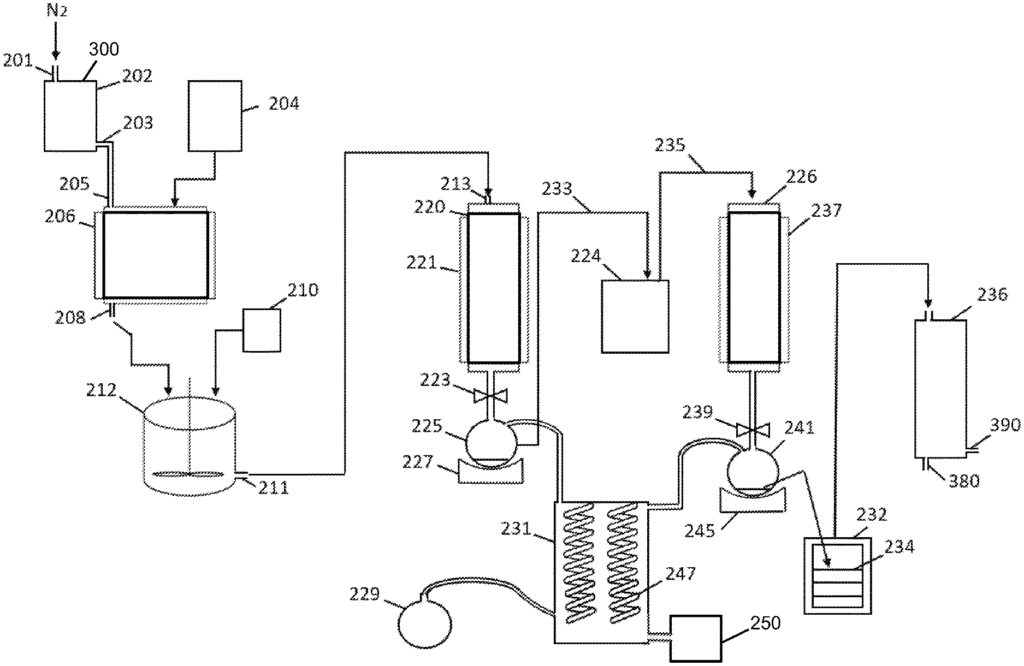

Efficient Cooling and Air Filtration with Multi-Stage Chilled Systems

Introduction

As industries and commercial spaces become more conscious of air quality and energy consumption, there is an increasing need for systems that can effectively purify air while maintaining energy efficiency. The patented elevated multi-stage chilled filter system offers a groundbreaking solution, providing both advanced air filtration and efficient cooling through a multi-stage approach. This innovative system is designed to maximize filtration performance while minimizing energy consumption, making it ideal for HVAC applications in a variety of settings, from industrial plants to commercial buildings.

Air Quality and Energy Efficiency Challenges in HVAC Systems

Maintaining clean, breathable air in commercial, industrial, and residential spaces requires sophisticated filtration systems that can remove contaminants and pollutants while ensuring a comfortable indoor environment. Traditional filtration systems, however, often struggle to balance efficient cooling with high-performance filtration. Many HVAC systems are energy-intensive, particularly when they must run continuously to maintain both air purity and temperature control. This can lead to high operating costs and reduced sustainability.

For businesses and industries that require both efficient air handling and cooling, finding a solution that optimizes filtration while reducing energy usage is critical. Whether in large-scale manufacturing facilities, data centers, or office buildings, the demand for cleaner air and lower energy consumption is driving innovation in the HVAC space.

Multi-Stage Filtration and Cooling for Optimal Performance

Our patented elevated multi-stage chilled filter system offers a highly efficient solution that integrates advanced cooling and multi-stage filtration processes. By elevating the filtration stages and combining them with chilled air, this system ensures that contaminants are captured and filtered out in stages, leading to improved air quality. The multi-stage approach allows for better particulate separation and removal, with each stage capturing smaller and more specific contaminants.

This technology is particularly effective in environments where air quality is critical, such as clean rooms, industrial plants, or data centers, where dust, pollutants, and airborne contaminants can interfere with operations. The chilled air component of the system helps maintain a controlled temperature while ensuring that energy consumption is kept low, making it a more sustainable solution than traditional systems. Its versatility makes it suitable for use in a variety of applications, including commercial office spaces, healthcare facilities, and industrial operations.

Key Benefits

- Advanced Filtration: Multi-stage filtration ensures better removal of contaminants and airborne pollutants, improving air quality.

- Energy-Efficient Cooling: Chilled air combined with filtration provides temperature control while reducing energy consumption.

- Versatile Applications: Suitable for use in commercial, industrial, and healthcare settings, enhancing both air quality and energy efficiency.

- Sustainability: Reduces the need for high-energy HVAC systems while providing effective filtration and cooling.

Innovative Air Filtration for Cleaner, Cooler Environments

Licensing this multi-stage chilled filter system technology offers HVAC companies, environmental engineers, and facility managers an advanced solution for improving air quality while reducing energy consumption. This system’s ability to integrate effective filtration with chilled cooling offers a sustainable way to meet the growing demand for cleaner, more energy-efficient air handling solutions.

- Abstract

- Claims

The invention claimed is:

1. A filtration system comprising a solvent vessel, a plurality of filter stages and the same plurality of transfer tubes wherein:

each filter stage has:

the solvent vessel has:

and the transfer tubes are each removably connected:

at an inlet end thereof to either:

13. The filtration system of claim 1, wherein:

Share

Title

Elevated multi-stage chilled filter system

Inventor(s)

Ryan Delmoral Ko

Assignee(s)

Nextleaf Solutions Ltd

Patent #

10646793

Patent Date

May 12, 2020