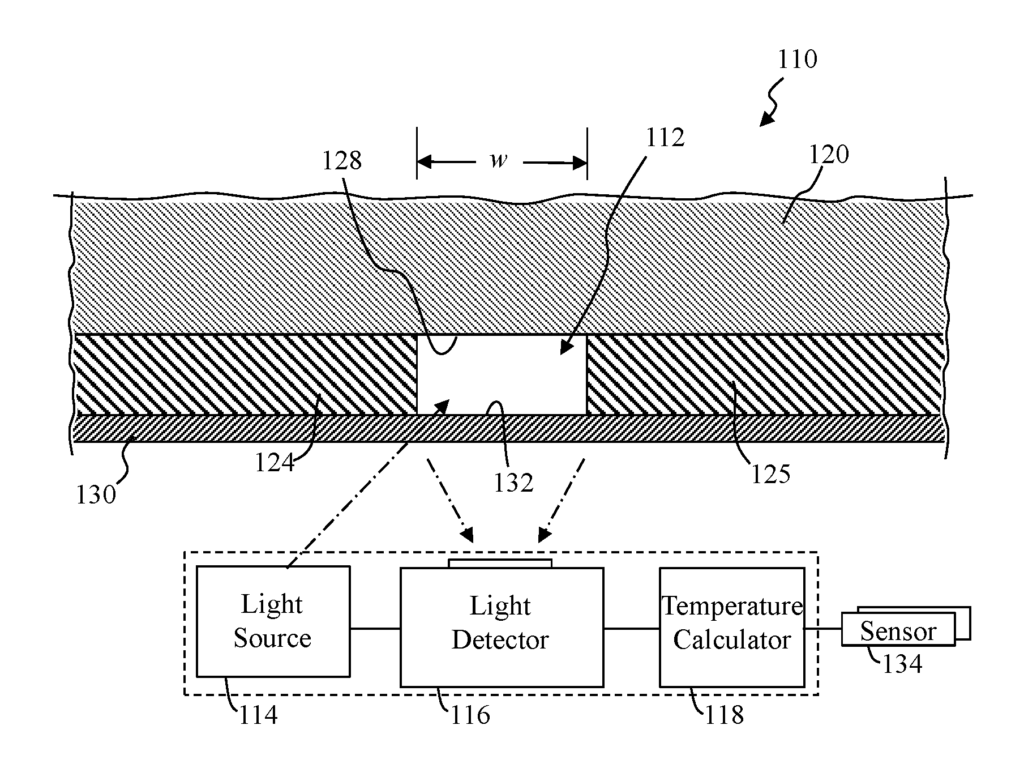

Precision Insights with Phonon-Based Temperature Measurement

Introduction

In today’s rapidly advancing fields like nanotechnology, electronics, and biotechnology, precision is everything. Devices and systems are shrinking, and with them, the ability to accurately measure, monitor, and regulate temperature at the nanoscale becomes increasingly essential. Our patented phonon-based temperature measurement technology offers a cutting-edge solution, allowing for unprecedented precision in tracking nanoscale temperatures.

Whether you’re working on next-gen semiconductor devices or cutting-edge biological research, the ability to monitor temperature at this level offers both enhanced performance and deeper insights. This breakthrough technology is designed to help industries that require extreme accuracy, ensuring that even the smallest changes in temperature are detected and managed.

Challenges in Nanoscale Temperature Monitoring

As devices become smaller and more complex, maintaining effective thermal management is crucial to avoid malfunction, degradation, or failure. Traditional temperature measurement methods often struggle to provide the accuracy needed for modern nanotechnology, especially when working at scales where even minor temperature fluctuations can affect performance.

In industries like electronics and biotech, heat generation and thermal conductivity must be managed carefully to maintain system integrity and performance. Without precise monitoring, it’s easy to miss these subtle but critical shifts, which can lead to inefficiencies, lower product lifespans, or outright system failures.

Why Choose Phonon-Based Temperature Measurement?

Our phonon-based temperature measurement system provides an elegant solution to these issues. By leveraging the phonon effect, this nanoscale technology measures temperature with remarkable precision, allowing for a deeper understanding of thermal behavior at the molecular level. This tool is invaluable for semiconductor development, where thermal efficiency is key to longevity and performance, as well as in biotechnology, where accurate temperature regulation can make or break delicate biological processes.

This technology is not only highly accurate but also adaptable. It can be applied across various industries to enhance thermal management, extend the lifespan of electronic devices, and improve product quality. With this patent, companies can stay ahead of the curve by adopting cutting-edge technology that elevates their thermal management and material characterization processes.

Key Benefits

- Unmatched Precision: Provides highly accurate temperature measurement at the nanoscale.

- Enhanced Performance: Ensures better thermal management in electronics, nanotech, and biotech applications.

- Versatile Applications: Can be used across a variety of industries, from semiconductor development to biological research.

- Cost-Efficient: Improves product performance and longevity, reducing operational costs over time.

Elevate Your Capabilities with Phonon-Based Measurement

Licensing this technology provides companies with a powerful tool for precision measurement, thermal management, and product innovation. Stay ahead in nanotechnology, electronics, and biotech with this groundbreaking solution for nanoscale temperature monitoring.

- Abstract

- Claims

What is claimed is:

Q=A(w 0 CT)−α

Q=A(w 0 CT)−α

Share

Title

Phonon effect based nanoscale temperature measurement

Inventor(s)

James S. Hammonds, Kimani A. Stancil

Assignee(s)

Howard University

Patent #

10520374

Patent Date

December 31, 2019