Precision Nanoparticle Handling with Electrostatic Trapping Technology

Introduction

Nanoparticles are critical to the future of science and technology, with applications spanning medicine, electronics, and environmental science. However, their minuscule size presents unique challenges in terms of handling, manipulation, and isolation. Traditional methods of capturing and studying nanoparticles often lack the precision required for high-stakes applications like drug delivery, semiconductor manufacturing, or environmental monitoring. Our patented nanoparticle electrostatic trap offers a solution to these challenges by enabling precise, non-invasive capture and manipulation of nanoparticles with unprecedented accuracy.

Limitations in Current Nanoparticle Handling Methods

Nanoparticles are central to many technological advances, but their small size and unique properties make them difficult to isolate and manipulate using conventional methods. Techniques such as centrifugation or filtration can cause contamination, damage, or even loss of the particles during handling. For industries relying on the purity and precise positioning of nanoparticles, such as semiconductor manufacturing or targeted drug delivery, these inefficiencies present major obstacles.

The need for a more accurate and controlled approach to isolating nanoparticles is critical across several fields. Whether it’s collecting nanoparticles from the environment for pollution analysis or precisely positioning them in electronic components, industries need tools that can offer better control over these tiny materials.

Electrostatic Trapping: A Game-Changer for Nanoparticle Control

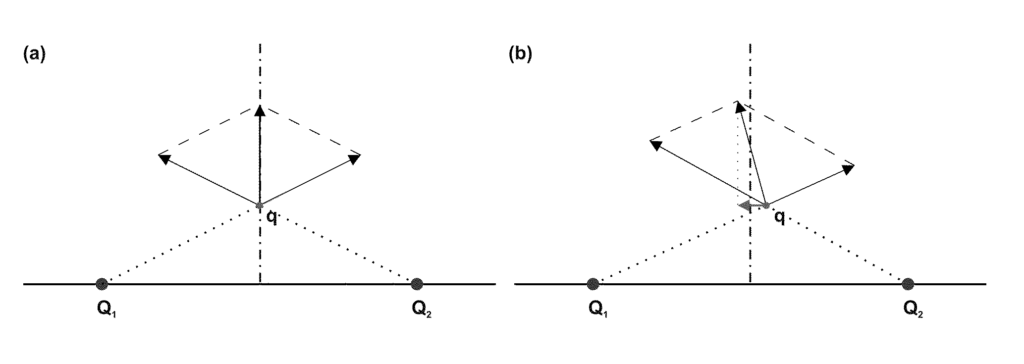

Our patented nanoparticle electrostatic trap provides a solution to the problem of handling and manipulating nanoparticles. This technology utilizes an electrostatic field to trap and hold nanoparticles without the need for physical contact. This non-invasive method ensures that nanoparticles remain pure and undamaged, making it ideal for applications requiring high precision.

The versatility of the electrostatic trap means that it can be used across a range of industries. In semiconductor manufacturing, it can improve the precision with which nanomaterials are placed onto substrates, leading to better-performing electronic devices. In biotechnology, it allows for the isolation of biological nanoparticles like proteins, viruses, or DNA fragments, supporting advanced research and development of therapies. Environmental scientists can use it to capture nanoparticles from the air or water, enabling more accurate monitoring of pollution levels and sources.

Key Advantages of the Technology

- Non-Contact Handling: Electrostatic trapping allows for precise control over nanoparticles without physical interference, preventing damage or contamination.

- Versatile Applications: From biotechnology to semiconductor manufacturing, this technology can be used in a wide variety of fields where nanoparticle manipulation is critical.

- Improved Precision: The system allows for highly accurate isolation and positioning of nanoparticles, enhancing performance in applications where precision is paramount.

- Scalability: The electrostatic trapping method can be adapted for both small-scale research and large-scale industrial applications.

Unlocking New Potential in Nanotechnology

Licensing this nanoparticle electrostatic trap technology offers businesses a powerful tool to lead in fields where nanoparticle manipulation is essential. By providing non-invasive, highly precise control over nanoparticles, this technology has the potential to improve processes in biotechnology, environmental monitoring, and semiconductor manufacturing, delivering both immediate benefits and long-term innovation.

- Abstract

- Claims

What is claimed is:

Share

Title

Nanoparticle electrostatic trap

Inventor(s)

Jorg C. Woehl, Christine A. Carlson

Assignee(s)

UWM Research Foundation Inc

Patent #

8465967

Patent Date

June 18, 2013