Precision Pinch Valve Pump for Safer Surgeries

Introduction

In surgical environments, precision in fluid management is critical. This patented pump system, equipped with a highly accurate pinch valve mechanism, addresses the unique needs of surgical fluid control. Designed for the complexity and high standards of surgical procedures, this pump offers precise, real-time fluid management, ensuring both patient safety and operational efficiency. Companies in the surgical equipment and medical devices industry can capitalize on this opportunity to deliver unparalleled fluid control solutions in surgery.

How It Works

The pump system utilizes a pinch valve design to regulate fluid flow with remarkable precision. Unlike traditional pumps, this system can quickly adjust flow rates and minimize interruptions, which is essential in dynamic surgical environments. The pinch valve design also reduces the risk of backflow and contamination, creating a more secure environment for fluid handling. Furthermore, its control interface is intuitive, enabling easy adjustments to accommodate varying surgical needs and complexities.

Key Benefits

- Enhanced Precision: The pinch valve design offers unmatched control over fluid flow, allowing surgeons and staff to adjust fluid rates accurately without disrupting the procedure.

- Safety and Reliability: The system minimizes contamination risk by maintaining closed, sterile fluid pathways. This is especially valuable in infection-prone environments, providing peace of mind for surgical teams.

- Real-Time Adjustments: Fluid requirements can change instantly during surgery. This pump allows for real-time flow adjustments, ensuring the surgical team can respond swiftly and with confidence.

- Reduced Downtime and Maintenance: The pinch valve system has fewer moving parts than traditional pumps, leading to less wear and tear. This reduces maintenance needs and increases the device’s lifespan, providing a cost-effective solution for healthcare facilities.

Why License This Technology

This pump system with a pinch valve mechanism is a transformative solution for fluid management in surgeries. For medical device companies, licensing this technology means gaining access to a high-value, reliable product that meets the stringent needs of modern surgical settings. Incorporating this system into product offerings enhances brand value and provides surgeons with a new tool for fluid control that increases accuracy, efficiency, and safety in the operating room. Embrace the opportunity to be at the forefront of surgical innovation with this cutting-edge fluid management system.

- Abstract

- Claims

What is claimed is:

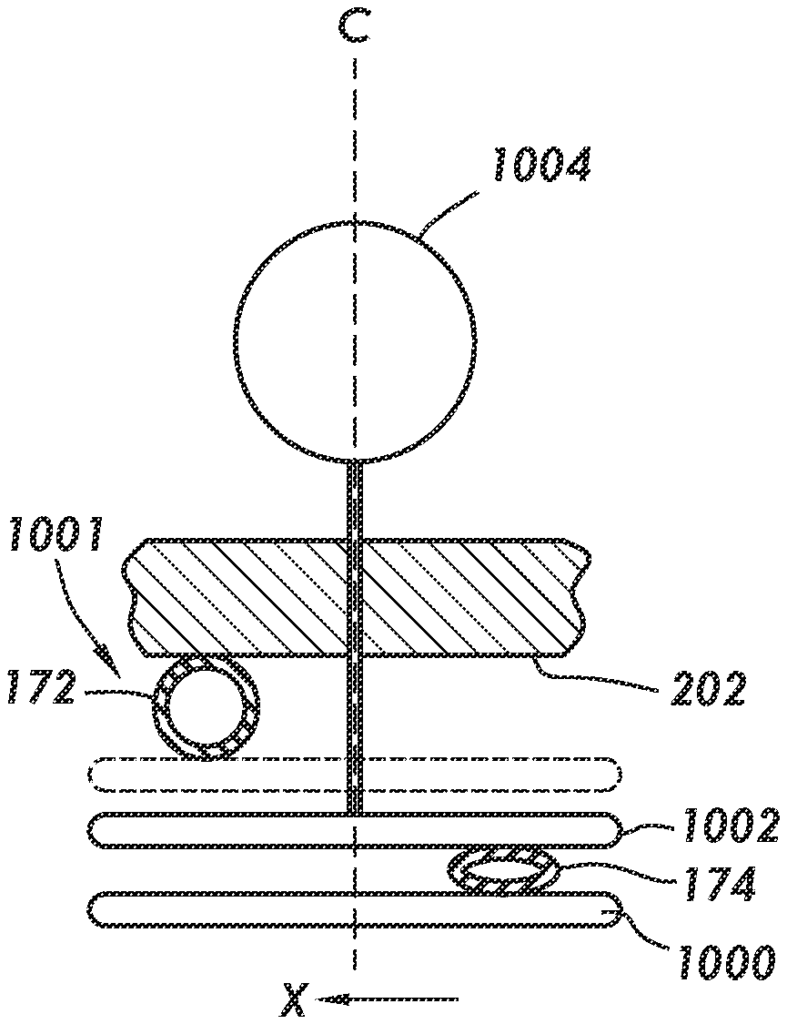

1. A pump system including an outflow pump, the pump system comprising:

a power actuator disposed in the internal volume and operably coupled to the at least one pinch member, the power actuator configured to have three orientations that define:

the power actuator including:

a solenoid assembly coupled to the sliding shaft, the sliding shaft movable by the solenoid assembly along the longitudinal central axis to:

2. The pump system as set forth in claim 1, wherein the solenoid assembly includes:

4. A pump system including an outflow pump, the pump system comprising:

a power actuator disposed in the internal volume and operably coupled to the at least one pinch member, the power actuator configured to have three orientations that define:

the power actuator including:

a solenoid assembly coupled to the sliding shaft, the sliding shaft movable by the solenoid assembly along the longitudinal central axis to:

Share

Title

Pump system with pinch valve for fluid management in surgical procedures and method of operation thereof

Inventor(s)

Mathew Mitchell, Mikhael LYSSOUNKINE, William Sant

Assignee(s)

Smith and Nephew Orthopaedics AG, Smith and Nephew Asia Pacific Pte Ltd, Smith and Nephew Inc

Patent #

11408416

Patent Date

August 9, 2022