Transforming Everyday Vibrations into Energy: Your Gateway to Next-Gen Piezoelectric Technology

Introduction

Imagine a world where the energy from every step you take, every vibration in the environment, is harnessed to power devices. Our patented “Method of Manufacture for Polymer Foam-Based Piezoelectric Material” (Patent #10522736) makes this vision a reality, offering a revolutionary material that converts mechanical energy into electrical energy with unparalleled efficiency.

The Innovation

Piezoelectric materials have long been valued for their ability to generate electricity from mechanical stress. However, traditional materials are often rigid, brittle, and expensive to produce. Enter our polymer foam-based piezoelectric material—a game-changer that combines flexibility, durability, and cost-effectiveness. This material is not just about generating energy; it’s about making energy generation accessible, versatile, and integrated into the fabric of everyday life.

Why This Matters

- Scalable and Cost-Effective Manufacturing: Our method leverages polymer foam, a lightweight and easily producible material, making it possible to scale up production without the prohibitive costs associated with traditional piezoelectrics. This opens up opportunities for widespread adoption across various industries.

- Flexible and Durable: Unlike conventional piezoelectric materials, our polymer foam-based solution is flexible and resilient, allowing it to be integrated into a wide range of products—from wearable technology and smart textiles to sensors embedded in infrastructure.

- Endless Applications: The potential uses are vast—imagine wearable devices that never need charging, sensors that draw energy from the vibrations of machinery, or even flooring that generates power as people walk across it.

The Opportunity

This is more than just a material—it’s the future of sustainable energy solutions. By licensing this patent, you’re not just adopting a technology; you’re becoming a leader in the next wave of energy innovation. Seize the opportunity to revolutionize how we think about energy with our polymer foam-based piezoelectric material.

- Abstract

- Claims

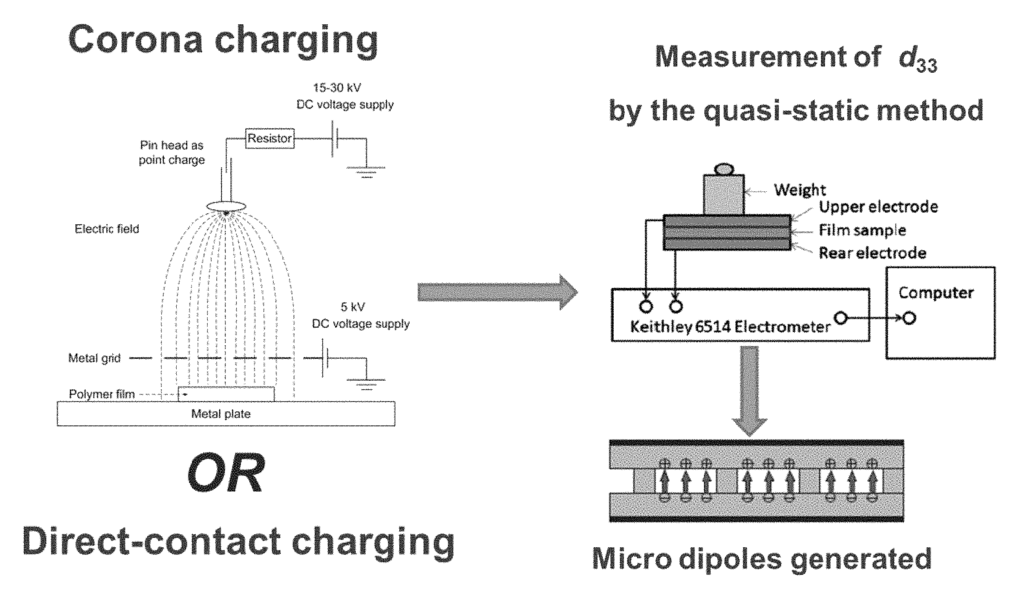

Thermally stable piezoelectric polymer foams (ferroelectrets) with high piezoelectric activity for sensing and actuation. The invention further includes a method of fabricating such foams in an environmentally friendly manner.

What is claimed is:

Share

Title

METHOD OF MANUFACTURE FOR POLYMER FOAM - BASED PIEZOELECTRIC MATERIAL

Inventor(s)

Changchun Zeng, Yan Li

Assignee(s)

Florida State University Research Foundation Inc

Patent #

10522736

Patent Date

December 31, 2019