Unlock the Future of Advanced Materials with Our Revolutionary Manufacturing Method for Macroscopic Nanomaterials

Introduction

In the rapidly advancing fields of nanotechnology and material science, the ability to manufacture macroscopic nanomaterials with precise control over their properties is a critical innovation. Our patented “Manufacturing of Macroscopic Nanomaterials Using Fluid Under Elevated Temperature and Pressure” (Patent #10196269) offers a groundbreaking approach that could redefine the production and application of nanomaterials across various industries.

The Challenge

Nanomaterials hold incredible potential due to their unique properties, such as high strength, lightweight, and superior electrical and thermal conductivity. However, the challenge has always been scaling these materials to macroscopic forms while maintaining their nanoscale properties. Traditional manufacturing methods often fail to deliver the consistency, scalability, and economic feasibility required for large-scale production, limiting the broader adoption of these advanced materials.

The Solution

Our patented method addresses these challenges by utilizing fluids under elevated temperature and pressure to manufacture macroscopic nanomaterials. This innovative process allows for the precise control of material properties while scaling production to meet industrial demands. Here’s why this technology is a game-changer and why you should consider licensing it:

- Scalability and Consistency: One of the most significant barriers in the nanomaterials industry is the ability to produce macroscopic quantities while retaining nanoscale properties. Our patented method enables the production of large-scale nanomaterials with consistent quality and performance. This scalability is essential for industries that require bulk materials with nano-enhanced properties, such as aerospace, automotive, and electronics.

- Enhanced Material Properties: The process allows for fine-tuning of material characteristics, such as strength, flexibility, and conductivity. This customization makes it possible to create materials tailored to specific applications, providing a competitive edge in markets where material performance is crucial. Whether you’re developing lightweight composites for aerospace or high-conductivity materials for electronics, this technology offers the flexibility to meet diverse needs.

- Cost-Effective Production: Traditional methods of producing nanomaterials often involve expensive and complex processes. Our method simplifies production by using fluid-based processing under controlled conditions, reducing the overall cost and complexity. This cost-efficiency makes it feasible to incorporate advanced nanomaterials into a wider range of products, driving innovation across multiple sectors.

- Versatility Across Industries: The potential applications for macroscopic nanomaterials are vast and varied. From stronger, lighter structural components to advanced thermal management systems and beyond, this technology has the versatility to impact numerous industries. By licensing this patent, you open the door to new product innovations and market opportunities.

- Environmental and Sustainability Benefits: Our method’s efficiency in using materials and energy contributes to a more sustainable production process. The ability to produce advanced materials with less waste and lower energy consumption aligns with global trends toward greener manufacturing practices. Licensing this technology not only offers commercial advantages but also supports your company’s commitment to sustainability.

The Opportunity

In today’s competitive landscape, the ability to innovate with advanced materials is a key differentiator. By licensing our patented manufacturing method, you gain access to a cutting-edge technology that can transform your product offerings and position your company at the forefront of material science innovation. This technology provides the tools to develop high-performance, cost-effective nanomaterials at scale, meeting the demands of tomorrow’s industries today.

Don’t miss the opportunity to lead in the next generation of material science. License this patent now and start manufacturing the future of advanced materials.

- Abstract

- Claims

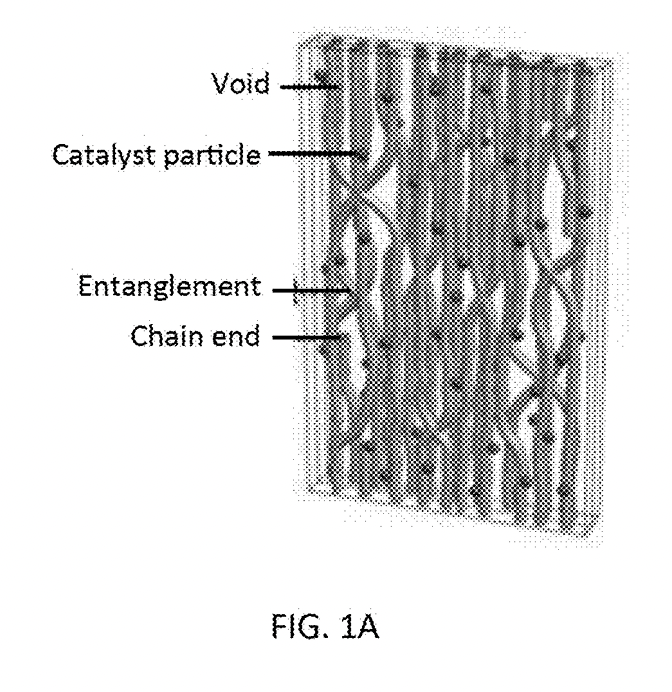

A process is disclosed for removing impurities from a carbon nanotube structure and then orienting the nanotubes within the structure . The process may use environmentally benign materials and minimize damage to the carbon nano tubes . The process may provide a cost – effective way to manufacture nanomaterials based macroscopic parts and components , whose properties approach to those of the individual nanoparticles .

What is claimed is:

1. A carbon nanotube structure, comprising:

a carbon nanotube buckypaper comprising a plurality of carbon nanotubes, wherein an impurity resulting from the formation of the plurality of carbon nanotubes has been removed from the carbon nanotube buckypaper and the plurality of carbon nanotubes have been substantially oriented by:

Share

Title

MANUFACTURING OF MACROSCOPIC NANOMATERIALS USING FLUID UNDER ELEVATED TEMPERATURE AND PRESSURE

Inventor(s)

Changchun Zeng, Zhiyong Liang, Yan Li, Jin Gyu Park

Assignee(s)

Florida State University Research Foundation Inc

Publication #

10196269

Publication Date

February 5, 2019