Advanced Multi-Layered Wound Dressing for Healing

Introduction

This advanced multi-layered wound dressing technology provides a superior solution for managing wounds, offering optimal protection while promoting faster healing. By combining multiple layers, each designed to address specific stages of the healing process, the dressing ensures that wounds are shielded from external contaminants, remain moist for optimal healing, and receive the necessary oxygen and nutrients for tissue regeneration. For companies in the medical devices and wound care industries, this technology offers a game-changing solution that improves patient outcomes and sets a new standard in wound management.

The Challenge: Ensuring Effective Wound Care

Wound care is a critical aspect of healthcare, especially in post-surgical, chronic, and trauma-related injuries. Traditional wound dressings often fail to provide the necessary protection or moisture balance needed for optimal healing, leading to slower recovery times and increased risk of infection. Healthcare providers need more advanced solutions that address these issues by offering comprehensive protection, moisture control, and a conducive environment for tissue repair. As patient care standards rise, there is a growing demand for innovative wound dressings that promote faster, safer, and more efficient healing.

Multi-Layered Dressing for Complete Wound Care

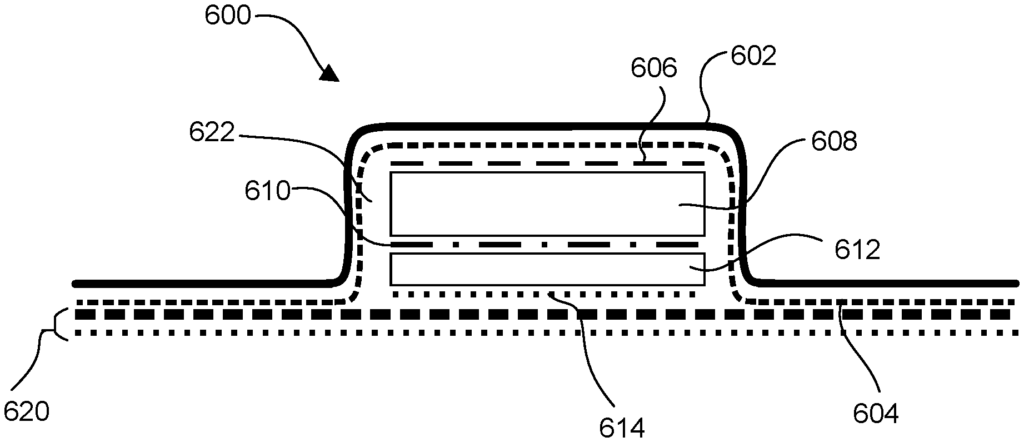

This multi-layered wound dressing technology addresses the key challenges of wound management by offering a dressing that is both protective and healing-oriented. The top layer provides a barrier against contaminants and bacteria, while the inner layers maintain an optimal moisture balance, allowing the wound to breathe while staying protected. The technology’s unique structure supports the wound during all stages of healing, from inflammation to tissue formation and repair. The dressing is also easy to apply and comfortable for patients, reducing the need for frequent changes and minimizing disruption to the healing process.

Key Benefits for Wound Care Providers and Manufacturers

For wound care product manufacturers, this multi-layered dressing offers a significant advancement in product design, meeting the demand for more effective and patient-friendly wound care solutions. Hospitals, clinics, and healthcare providers can integrate this dressing into their wound management protocols to improve recovery times, reduce the risk of infection, and enhance patient comfort. The dressing is particularly useful in post-surgical care, chronic wound management, and trauma care, making it a versatile tool for healthcare professionals dedicated to improving patient outcomes.

Invest in Next-Level Wound Healing Solutions

Licensing this multi-layered wound dressing technology provides your company with an opportunity to lead in the growing field of advanced wound care. By offering a dressing that enhances protection, accelerates healing, and improves patient comfort, your business can meet the increasing demand for innovative wound care products. This technology represents a valuable investment for companies focused on delivering high-performance medical solutions that prioritize patient recovery and safety.

- Abstract

- Claims

The invention claimed is:

1. A multi-layered wound dressing comprising:

18. A method of manufacturing a multi-layered wound dressing, the method comprising:

Share

Title

Multi-layered wound dressing and method of manufacture

Inventor(s)

Daniel Lee Steward, Emma Cole, Hannah Bailey Sidebottom, Neil Patrick

Assignee(s)

Smith and Nephew PLC, TJ Smith and Nephew Ltd

Patent #

11559437

Patent Date

January 24, 2023