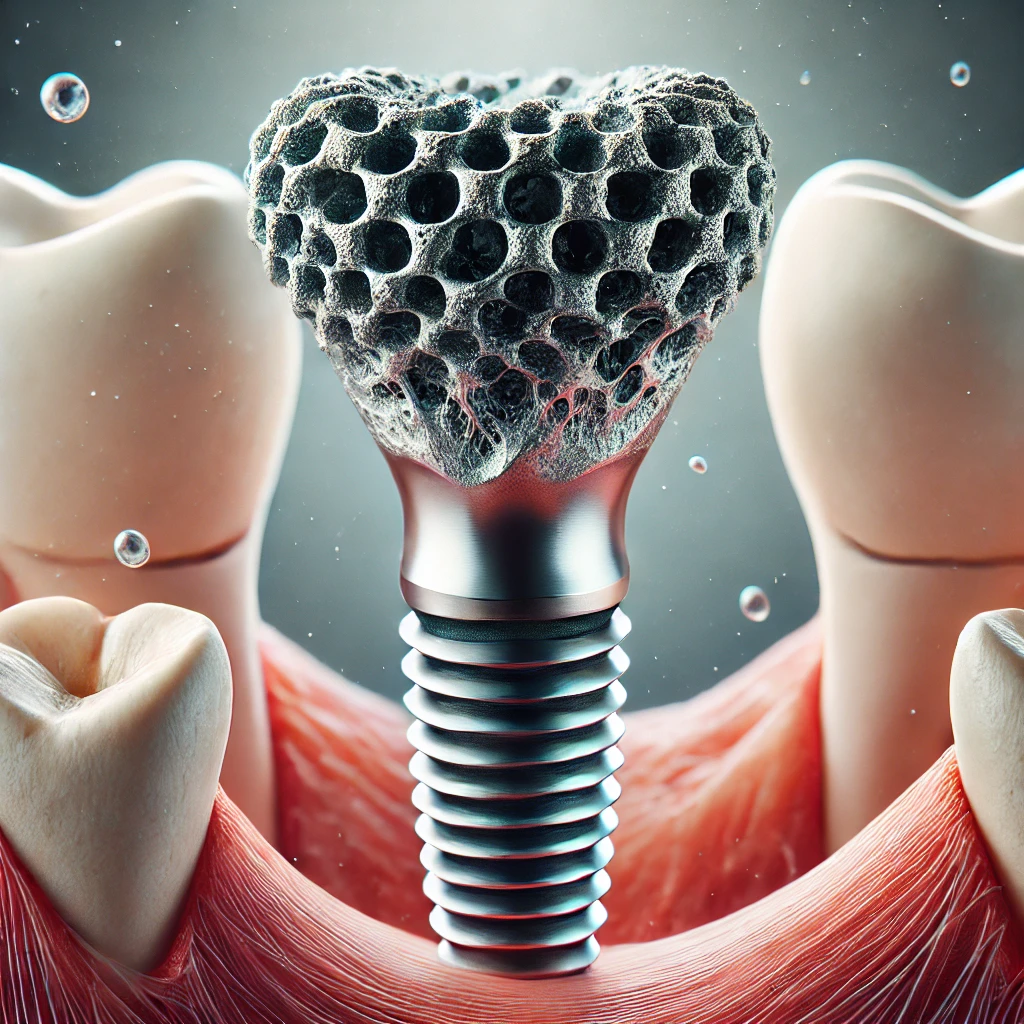

Composite Coating for Titanium Implants

Introduction

- Abstract

- Claims

1. A method for preparing a composite coating on an implant comprising:

11. The method of claim 1, wherein an amount of the dispersed carbon nanoparticles included in the aqueous electrolytic solution is between 0.05% and 1.5% by total weight of the aqueous electrolytic solution and is calculated by:

mGO[g]=m r[g]·% GO

12. A method for preparing a composite coating on a titanium implant for tissue engineering comprising:

20. The method of claim 12, wherein an amount of the dispersed carbon nanoparticles included in the aqueous electrolytic solution is between about 0.05% and 1.5% by total weight of the aqueous electrolytic solution and is calculated by:

mGO[g]=m r[g]·% GO

22. The implant with a composite coating of claim 21, wherein an amount of the dispersed carbon nanoparticles included in the aqueous electrolytic solution is between about 0.05% and 1.5% by total weight of the aqueous electrolytic solution and is calculated by:

mGO[g]=m r[g]·% GO

Share

Title

Method for obtaining a composite coating on titanium implants for tissue engineering

Inventor(s)

Bartlomiej Wysocki, Danuta Leszczynska, Wojciech Swieszkowski, Krzysztof Jan Kurzydlowski

Assignee(s)

Jackson State University

Patent #

20170088969

Patent Date

March 30, 2017