Eco-Friendly Durability with Nano-Engineered Bioplastics

Introduction

Imagine a bioplastic so innovative that it combines natural strength and sustainability in a single material. Our nano-engineered eggshell biopolymer blend offers an exceptional solution for industries looking to reduce plastic waste without sacrificing durability or performance.

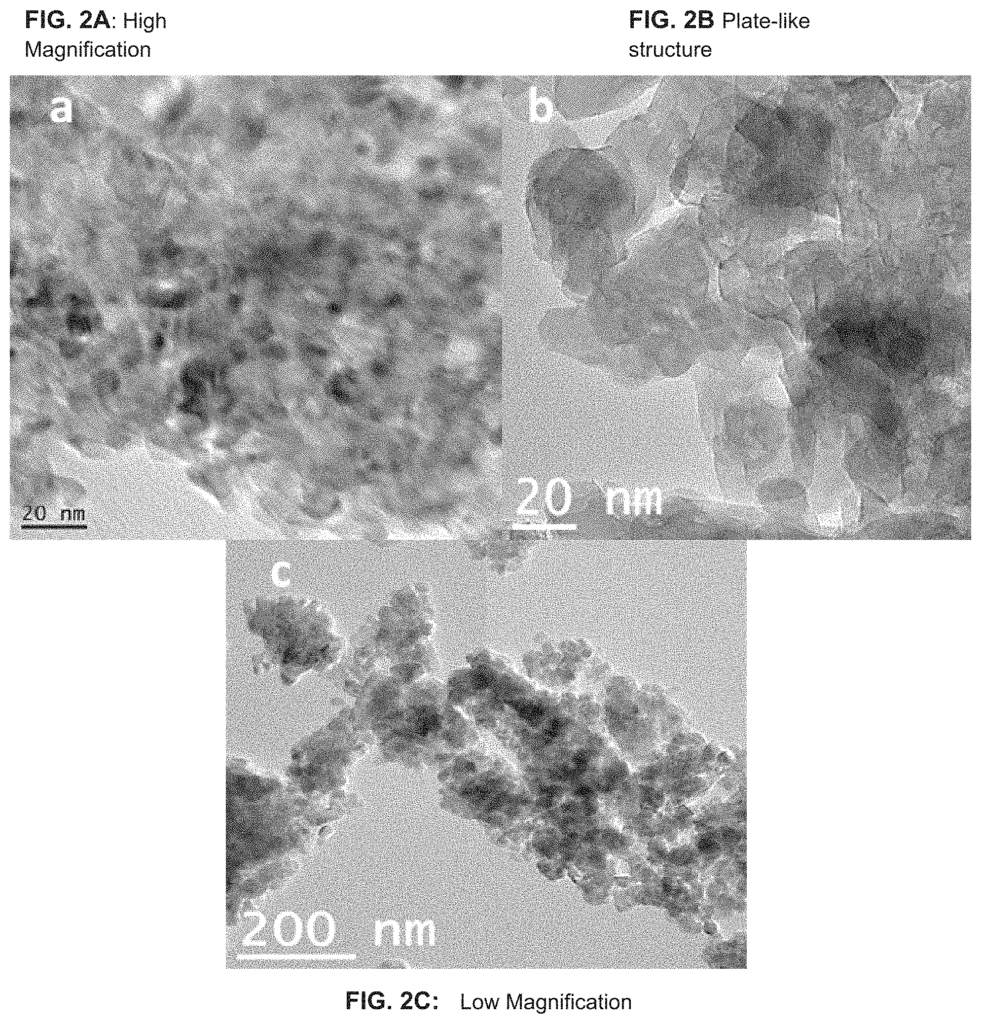

This biopolymer blend, made from carefully selected, nano-engineered eggshell particles, creates a flexible yet sturdy film designed for diverse applications. Its resilience makes it perfect for packaging, consumer goods, and other products where sustainability and reliability are essential. The unique combination of materials in this bioplastic blend provides an advanced level of biodegradability, breaking down faster and more efficiently than conventional bioplastics, while maintaining structural integrity in daily use.

In addition to its biodegradability, this bioplastic is adaptable. It can be customized to meet specific needs for thickness, flexibility, and resistance, ensuring the perfect balance of performance and environmental responsibility. Manufacturers in sectors from food packaging to retail can now deliver eco-friendly products that meet consumer demand for sustainable options without compromising on quality.

Licensing this technology means embracing a future-focused, earth-friendly material designed for seamless integration into existing production lines. With the need for sustainable solutions growing every day, now is the time to lead in eco-conscious innovation.

- Abstract

- Claims

The invention claimed is:

Share

Title

Nano engineered eggshell flexible biopolymer blend and methods of making biopolymer blend film and using such bioplastic blends for improved biodegradable applications

Inventor(s)

Vijaya Rangari, Boniface Tiimob

Assignee(s)

Tuskegee University

Patent #

11613648

Patent Date

March 28, 2023