Efficient Propulsion for the Next Era of Space Exploration

Introduction

The space industry is experiencing a surge of innovation, with small satellites and CubeSats leading the charge. As missions demand more precision, longer durations, and cost-effective solutions, propulsion systems need to be lightweight, efficient, and reliable. Our micro-cathode arc thruster technology delivers on all these fronts, offering a highly effective propulsion system for small-scale spacecraft and satellite missions.

The Challenge

Traditional propulsion systems, while effective for large spacecraft, are often too bulky, inefficient, or costly to scale down for small satellites and CubeSats. As the demand for these smaller satellites grows, especially in communications, Earth observation, and scientific research, there’s a need for propulsion systems that can deliver reliable thrust in a compact form factor, while maintaining high efficiency and cost-effectiveness.

The Solution

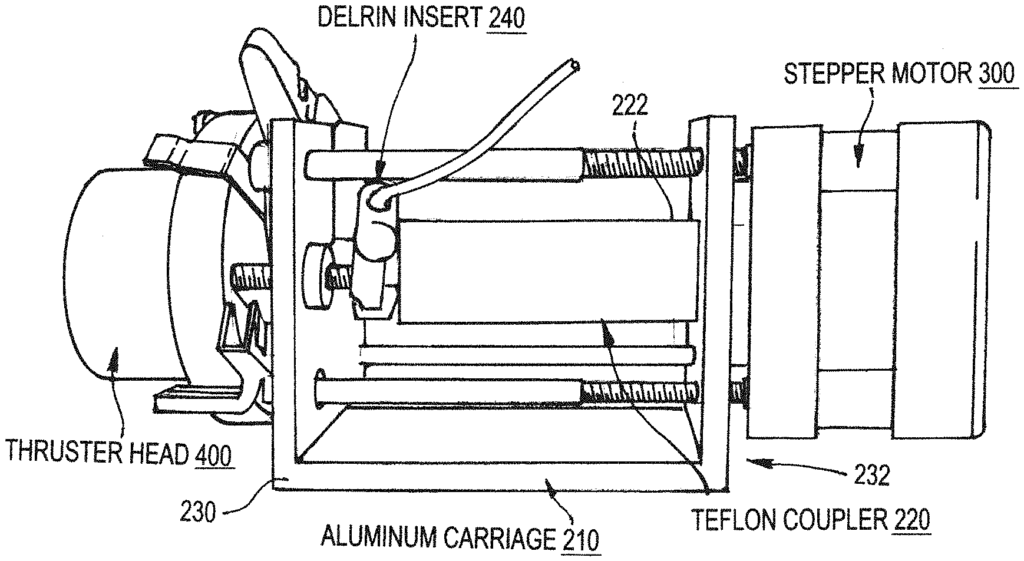

Our micro-cathode arc thruster technology provides a compact, scalable solution to propulsion challenges for small satellites and CubeSats. It generates thrust using a cathode arc, ejecting ionized material to produce propulsion with minimal fuel consumption. This technology enables precise maneuvering, orbit adjustments, and station-keeping for small satellites, ensuring they remain operational and effective throughout their mission lifecycle.

Key Benefits

- Compact and Lightweight Design: The micro-cathode arc thruster is designed specifically for small spacecraft. Its compact size and lightweight nature make it the ideal solution for CubeSats and other small satellites, where space and mass are at a premium.

- High Efficiency with Low Fuel Consumption: This thruster operates with minimal fuel requirements, allowing satellites to extend their operational life without the need for frequent refueling. This is especially important for long-duration missions where fuel efficiency is critical.

- Precision Control: Our thruster provides precise control over satellite movement, enabling accurate orbit adjustments, station-keeping, and de-orbiting maneuvers. This is crucial for both commercial and scientific missions that require fine-tuned propulsion capabilities.

Why License This Technology?

Licensing this micro-cathode arc thruster technology offers aerospace companies and satellite manufacturers a cutting-edge propulsion solution that meets the demands of modern space missions. It allows for efficient, precise, and cost-effective propulsion for small spacecraft, ensuring mission success while optimizing fuel usage and reducing operational costs.

Conclusion

As the commercial space industry continues to grow, propulsion systems must evolve to keep pace with smaller, more agile spacecraft. By licensing this micro-cathode arc thruster, you’ll have access to a propulsion system that’s ready to meet the challenges of the future of space exploration.

- Abstract

- Claims

The invention claimed is:

1. An arc thruster comprising:

15. A method of operating an arc thruster having a cathode, an anode insulated by a dielectric insulator, a stepping motor and a rod, the method comprising:

20. An arc thruster comprising:

Share

Title

Micro-cathode arc thruster

Inventor(s)

Michael Keidar, George Teel, Samantha A. HURLEY

Assignee(s)

George Washington University

Patent #

10738776

Patent Date

August 11, 2020