Efficient Vaporization with Advanced Airflow Technology

Introduction

Vaporization technology has gained significant traction in recent years, from recreational use in vaping to medical applications in delivering inhalable treatments. However, one of the major limitations in existing vaporization devices is inconsistent atomization, leading to wasted concentrates and suboptimal user experiences. Our patented conjunctive airflow atomizer introduces an advanced system for vaporizing concentrates with precision and efficiency, offering a superior experience for consumers and medical patients alike. This technology is designed to optimize airflow, enhance concentrate atomization, and deliver a smoother, more controlled vaporization process.

Limitations in Current Vaporization Devices

Vaporization devices have become increasingly popular across various industries, particularly in the vaping and aromatherapy sectors. Despite their wide adoption, most vaporization devices struggle with issues like uneven heating, improper airflow management, and inefficient atomization of concentrates. This often results in inconsistent vapor quality, wasted materials, and an overall lack of control in the vaporization process.

For manufacturers and users alike, the need for more advanced airflow management systems that ensure consistent atomization is critical. Devices that fail to efficiently vaporize concentrates leave users with diminished experiences, leading to dissatisfaction and, ultimately, loss of product value.

A New Standard in Vaporization with Conjunctive Airflow Atomizers

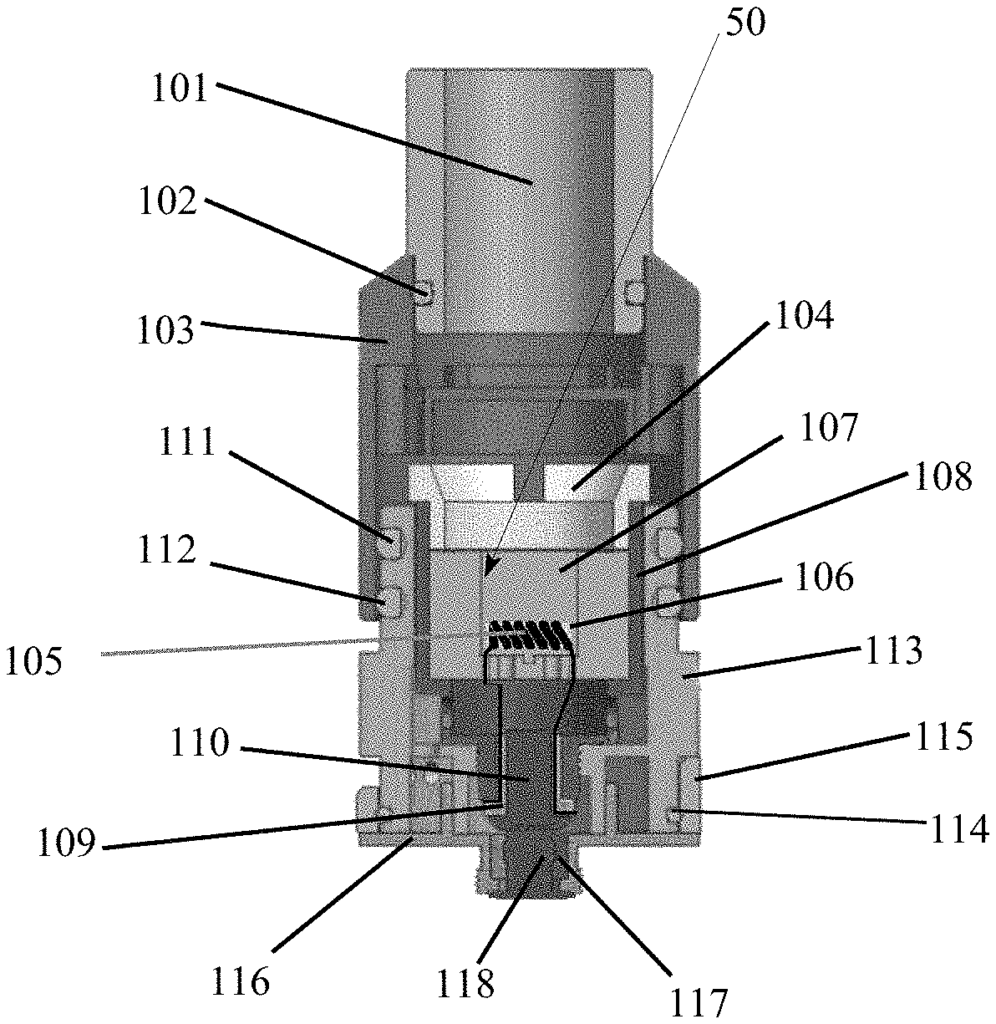

Our patented conjunctive airflow atomizer represents a major advancement in vaporization technology. The system is designed to optimize the airflow around the concentrate, creating a more consistent and efficient vaporization process. By integrating conjunctive airflow, the atomizer ensures that the concentrates are exposed to the right amount of heat and air, producing smoother vapor and minimizing waste.

This technology is highly versatile, capable of being adapted for use in recreational vaporizers, medicinal inhalation devices, and even aromatherapy diffusers. The precise atomization process guarantees that the concentrate is used efficiently, offering users more control over the experience while ensuring better delivery of active ingredients. For manufacturers, this system offers a way to differentiate their vaporization devices by providing a superior product with enhanced vapor quality and efficiency.

Key Benefits

- Improved Atomization: Ensures more consistent vapor production by optimizing airflow and heat distribution.

- Efficient Use of Concentrates: Minimizes waste by vaporizing the concentrate more effectively, providing better value for the user.

- Smoother User Experience: Reduces harshness and inconsistencies in vapor quality, offering a more enjoyable experience.

- Versatile Application: Ideal for use in vaping devices, medical inhalation products, and aromatherapy diffusers.

Delivering Precision and Efficiency in Vaporization

Licensing this conjunctive airflow atomizer technology offers manufacturers in the vaporization, medical, and consumer electronics industries a unique opportunity to enhance their product offerings. With its advanced airflow control and efficient atomization capabilities, this technology is set to improve user satisfaction and product performance across various applications.

- Abstract

- Claims

What is claimed is:

Share

Title

Conjunctive airflow atomizer for concentrates

Inventor(s)

Sai Stephen Rose

Assignee(s)

Rose Sai Stephen

Patent #

10779573

Patent Date

September 22, 2020