Harnessing the Power of Surface Acoustic Waves for Advanced Semiconductor Applications

Introduction

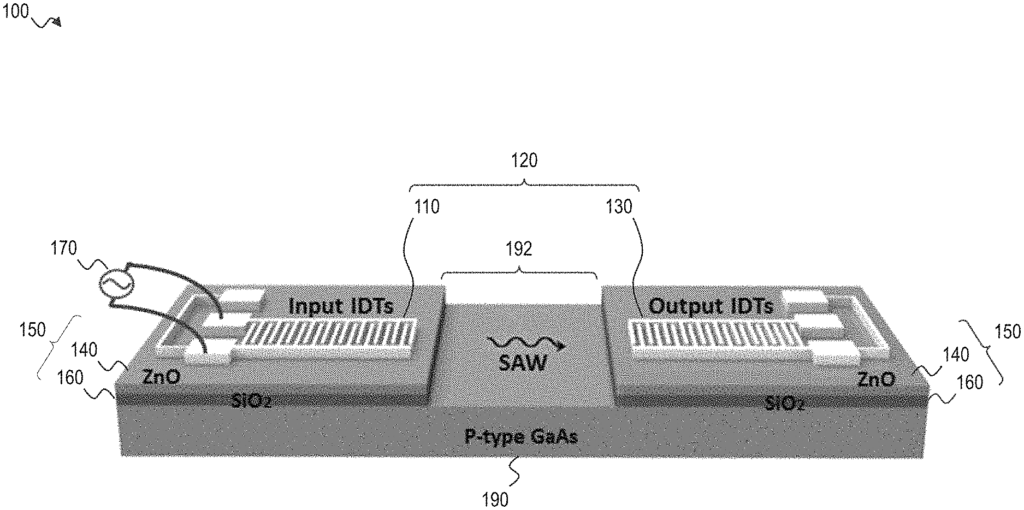

In today’s rapidly evolving technological landscape, the demand for faster, smaller, and more efficient electronic components continues to grow. Surface acoustic wave (SAW) technology offers a unique solution for a range of applications, from telecommunications to quantum computing. Our innovative method for generating and enhancing surface acoustic waves on highly doped p-type III-V semiconductor substrates unlocks new possibilities for high-performance electronics and devices.

The Challenge

Current surface acoustic wave technologies, while effective, are often limited by the materials they rely on, particularly in high-frequency applications. Traditional semiconductor substrates can struggle to meet the demands of modern devices that require both high-speed signal processing and precision. As a result, industries like telecommunications and advanced sensing are in need of a more efficient, scalable solution for generating surface acoustic waves.

The Solution

Our patented approach utilizes highly doped p-type III-V semiconductor substrates to generate and enhance surface acoustic waves, significantly improving performance and reliability. This method not only increases the efficiency of surface wave generation but also provides enhanced control over wave propagation, leading to improved signal processing capabilities. Whether for use in RF filters, sensors, or other semiconductor devices, this technology offers a pathway to enhanced performance and smaller, more efficient components.

Key Benefits

- High-Speed Signal Processing: By enhancing the generation of surface acoustic waves, this technology enables faster, more efficient signal processing. It’s ideal for applications in telecommunications, where high-frequency RF filters are essential for modern wireless communication systems.

- Improved Device Performance: The use of highly doped III-V semiconductor substrates leads to enhanced control over wave propagation, resulting in more accurate and reliable devices. This is especially beneficial for sensors, oscillators, and other components that require precise signal processing.

- Versatile Applications: From advanced acoustic sensors and RF filters to potential uses in quantum computing, this technology offers versatility across multiple industries. Its ability to integrate with existing semiconductor manufacturing processes makes it scalable for a wide range of applications.

Why License This Technology?

Licensing this advanced SAW technology positions your company at the forefront of semiconductor innovation. With its potential to improve performance in telecommunications, electronics, and beyond, this solution offers a unique advantage in developing the next generation of high-performance devices.

- Abstract

- Claims

Share

Title

Generation and enhancement of surface acoustic waves on a highly doped p-type III-V semiconductor substrate

Inventor(s)

Boqun Dong, Mona Zaghloul

Assignee(s)

George Washington University

Patent #

11211913

Patent Date

December 28, 2021