Improving Surgical Precision with an Advanced Bone Cement Mixing Method

Introduction

Bone cement plays a critical role in orthopedic surgeries, especially for joint replacements such as hip and knee surgeries. Its proper preparation is essential to ensure long-term stability and success of the implanted prosthesis. However, achieving the ideal consistency and uniformity can be challenging with traditional mixing methods, which may lead to weaker bonds or uneven application during surgery. Our method of mixing bone cement with two paddles provides an innovative solution to improve the quality of bone cement while simplifying the surgical process.

The Challenge

In orthopedic procedures, surgeons rely on bone cement to secure implants in place. However, traditional single-paddle mixing methods can often produce inconsistencies in the cement’s texture and homogeneity. These inconsistencies increase the risk of implant failure, loosening, or reduced durability over time, leading to revision surgeries and extended recovery periods for patients. Additionally, mixing bone cement with a single paddle requires more time and effort, which can extend operating times and increase the risk of complications during surgery.

The Solution

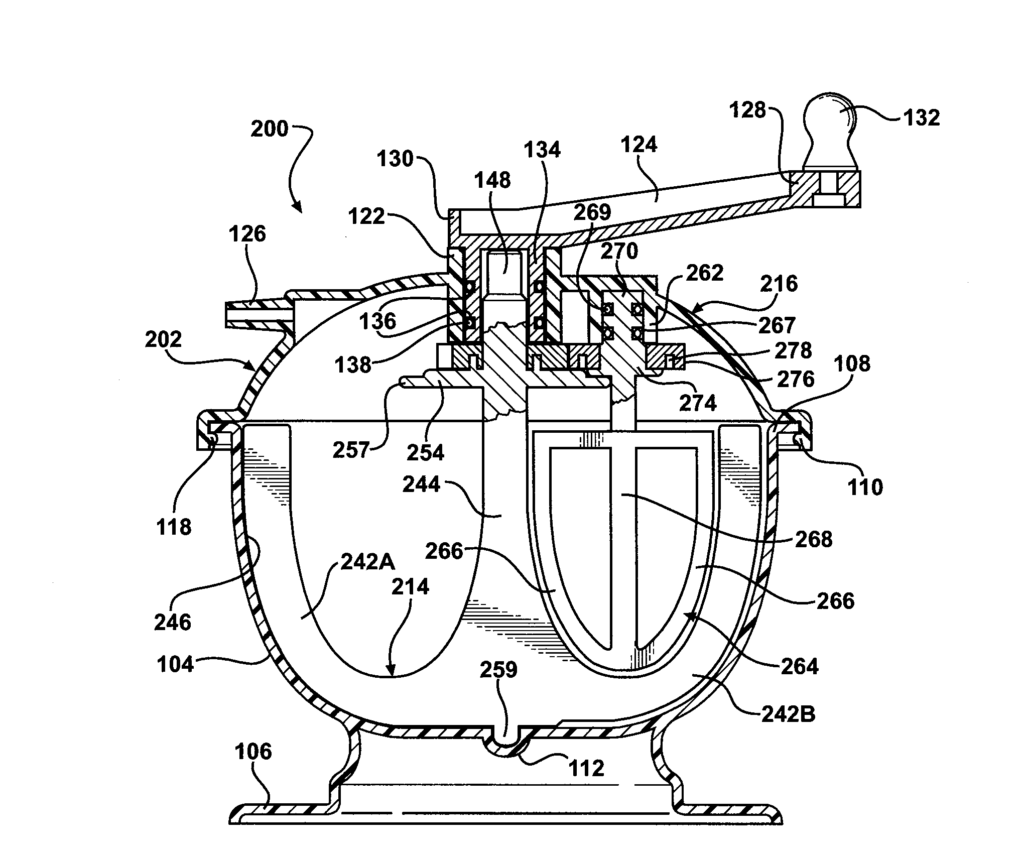

Our patented dual-paddle mixing method addresses these challenges by introducing a more effective approach to preparing bone cement. The two-paddle system ensures that the cement is mixed evenly and thoroughly, achieving optimal consistency in less time than traditional methods. This approach reduces the risk of air bubbles and uneven distribution, providing a stronger, more reliable bond between the implant and bone.

This method not only improves the quality of the bone cement but also enhances the efficiency of the mixing process. With faster preparation times, surgeons can apply the cement more quickly, reducing operating time and minimizing the risks associated with prolonged surgeries. The dual-paddle design is also easy to implement in surgical settings, making it accessible for healthcare teams.

Key Benefits

- Enhanced Cement Quality: Achieve uniform consistency and reduced air bubbles, resulting in a stronger and more durable bond between the bone and implant.

- Reduced Operating Time: The dual-paddle system speeds up the mixing process, allowing for quicker application during surgery, improving surgical efficiency.

- Improved Patient Outcomes: By ensuring optimal bone cement preparation, this method reduces the likelihood of implant loosening or failure, leading to faster recovery and fewer revision surgeries.

- Easy Integration: The method is simple to integrate into existing surgical workflows, requiring minimal adjustments for healthcare providers.

Why License This Technology?

By licensing this method, you will offer surgeons a more efficient and reliable way to prepare bone cement, improving patient outcomes and surgical success. It provides an opportunity to elevate the standard of care in orthopedic surgery, ensuring stronger bonds, quicker procedures, and lasting results for patients.

- Abstract

- Claims

1. A method of mixing bone cement, said method including the steps of:

simultaneously rotating both the first and second paddles so that, simultaneously:

2. The method of mixing bone cement of claim 1, wherein:

3. The method of mixing bone cement of claim 1, wherein:

4. The method of mixing bone cement of claim 1, wherein:

5. The method of mixing bone cement of claim 1, wherein:

6. The method of mixing bone cement of claim 1, wherein:

9. A method of mixing bone cement, said method including the steps of:

10. The method of mixing bone cement of claim 9, wherein:

11. The method of mixing bone cement of claim 9, wherein:

12. The method of mixing bone cement of claim 9, wherein:

the second paddle is shaped so as to have: first and second vanes that are spaced apart, both second paddle vanes being located between the first paddle shaft and the inner edges of the first paddle vanes; and a cross beam that connects the second paddle vanes, the cross beam being located above space occupied by the first paddle first vane base section, so that during said simultaneous rotation of the paddles:

14. The method of mixing bone cement of claim 9, wherein:

the second paddle vane is shaped to have:

15. The method of mixing bone cement of claim 14, wherein:

16. A method of mixing bone cement, said method including the steps of:

simultaneously with said rotation of the first paddle, rotating a second paddle in the housing interior space, the second paddle having a shaft that is radially offset from the first paddle shaft and at least one vane that is connected to and radially offset from the second paddle shaft, the second paddle vane shaped and positioned so that, as the second paddle is rotated, the second paddle vane rotates between the first paddle shaft and the first paddle vanes and, during said rotation:

17. The method of mixing bone cement of claim 16, wherein the second paddle vane is shaped to have:

18. The method of mixing bone cement of claim 16, wherein the second paddle is shaped to have:

20. The method of mixing bone cement of claim 16, wherein:

Share

Title

Method of mixing bone cement with two mixing paddles

Inventor(s)

Christopher Matthew Tague, Richard F. Huyser, Jared Paul Coffeen, Christopher Scott Brockman

Assignee(s)

Stryker Corp

Patent #

7645066

Patent Date

January 12, 2010