Innovative Ear Pressure Equalization System

Introduction

This tympanic membrane pressure equalization tube delivery system provides a safer and more efficient method for treating patients with chronic ear infections or Eustachian tube dysfunction. Designed to deliver pressure equalization tubes with precision, this system reduces the risks associated with traditional procedures and enhances the patient experience. For medical device companies and healthcare providers, this technology offers an advanced solution to a common problem in pediatric and adult ear care, ensuring better outcomes with minimal discomfort.

The Challenge: Treating Chronic Ear Infections Safely

Chronic ear infections and persistent Eustachian tube dysfunction are particularly prevalent among children, often requiring the placement of pressure equalization (PE) tubes to prevent fluid buildup and improve hearing. Traditional methods of inserting these tubes can be invasive, uncomfortable, and carry risks of complications. This has led to a growing demand for more precise and less traumatic delivery systems that ensure accurate placement of tubes while minimizing patient discomfort. Healthcare professionals need reliable devices that simplify the procedure and improve overall outcomes.

Precision Delivery for Effective Treatment

This innovative ear pressure equalization system addresses these challenges by offering a delivery method that enhances the precision and control of tube placement. The system is designed to streamline the insertion process, reducing the potential for complications, and making the procedure safer for patients, especially in pediatric cases. Its intuitive design allows healthcare professionals to perform the procedure more quickly and with greater accuracy, ensuring that the PE tubes are securely placed for optimal pressure equalization. The system’s improved delivery mechanism also helps reduce discomfort and recovery time for patients.

Key Benefits for Healthcare Providers and Patients

For healthcare providers, this technology offers a significant advantage by improving the efficiency and safety of PE tube placements. Otolaryngologists and audiologists can use this system to provide better care for patients with chronic ear infections, reducing the need for repeat procedures and minimizing the risk of complications. Pediatricians will benefit from the system’s ability to make the procedure less traumatic for children, while healthcare facilities can reduce the overall costs and time associated with ear surgeries. For patients, especially children, this system ensures a more comfortable, effective treatment with faster recovery.

Invest in Advanced Ear Care Solutions

Licensing this ear pressure equalization system positions your company at the forefront of medical device innovation in ear care. By offering a more effective and patient-friendly solution for PE tube placement, your business can meet the growing demand for safer, more efficient ear treatments. This technology provides an opportunity to improve patient outcomes, simplify procedures, and enhance the quality of care in both pediatric and adult ear health. It’s a valuable investment for companies looking to deliver cutting-edge solutions in the field of otolaryngology.

- Abstract

- Claims

What is claimed is:

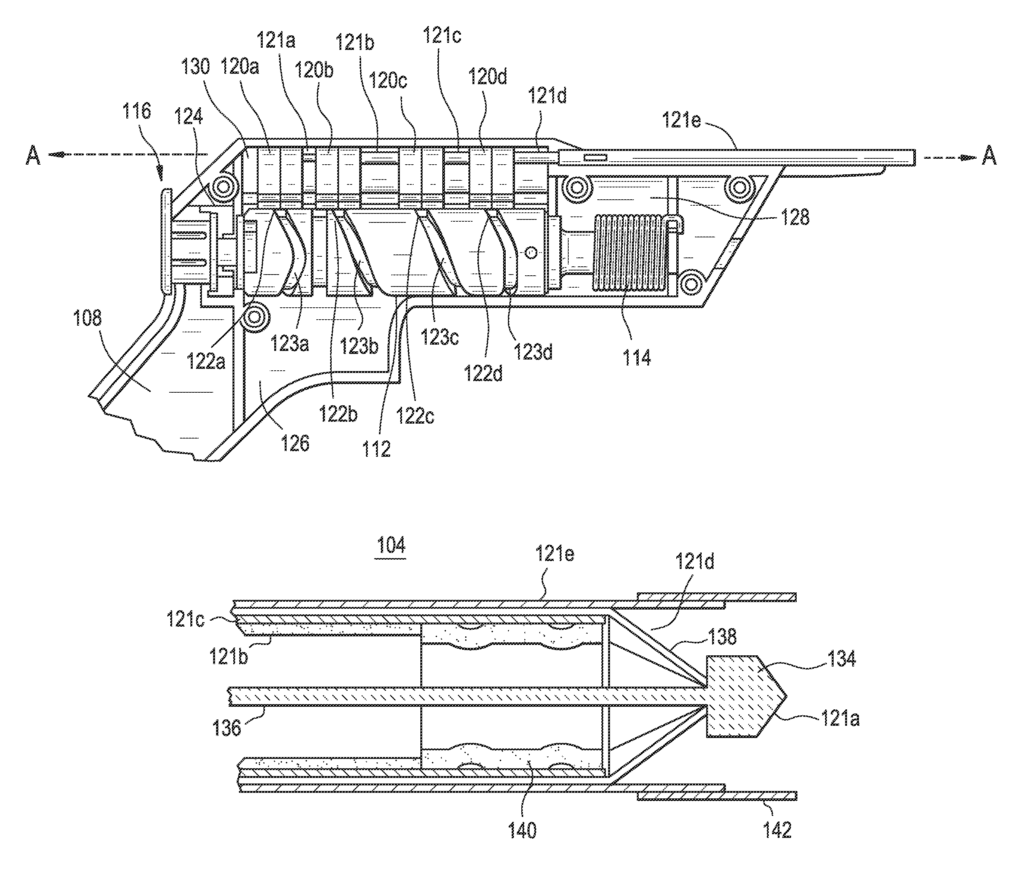

1. A system for forming an incision in a tympanic membrane and delivering a pressure equalization tube into the incision, the system comprising:

(b) an elongate shaft assembly coupled with the housing, the shaft assembly comprising:

(c) a cam assembly comprising:

24. A system for forming an incision in a tympanic membrane and delivering a pressure equalization tube into the incision, the system comprising:

(b) an elongate shaft assembly coupled with the housing, the shaft assembly comprising:

Share

Title

Tympanic membrane pressure equalization tube delivery system

Inventor(s)

Greg Liu, Rohit Girotra, John H. Morriss, Julie D. Vrany, Hung V. Ha, Bryan Knodel, Jeffrey A. Walker, Thomas Daniel Gross, Mathew D. Clopp, Bernard H. Andreas

Assignee(s)

Tusker Medical Inc

Patent #

8864774

Patent Date

October 21, 2014