Innovative Photoelectrode Technology for Enhanced Solar Energy Conversion

Introduction

As the demand for clean, renewable energy continues to grow, optimizing the efficiency of solar energy conversion systems is becoming increasingly important. Traditional solar technologies face limitations in energy conversion rates and scalability, requiring innovative solutions that push the boundaries of material science. Our patented photoelectrode technology offers an advanced solution for improving solar energy capture, conversion, and storage, making it a valuable asset for companies invested in renewable energy and sustainable power systems.

Challenges in Current Solar Energy Technologies

Solar energy is one of the most promising sources of renewable energy, but current photovoltaic and solar cell technologies often suffer from inefficiencies in energy conversion. Traditional materials used in these devices have limitations in terms of durability, energy absorption, and conversion rates. This leads to suboptimal performance and higher costs for large-scale solar energy installations. The challenge is to develop materials that not only capture more sunlight but also convert it more efficiently into usable energy, while remaining scalable and cost-effective.

For companies operating in the renewable energy sector, the ability to improve solar energy technologies without a dramatic increase in production costs is essential for meeting market demand and environmental goals.

A New Approach with Advanced Photoelectrodes

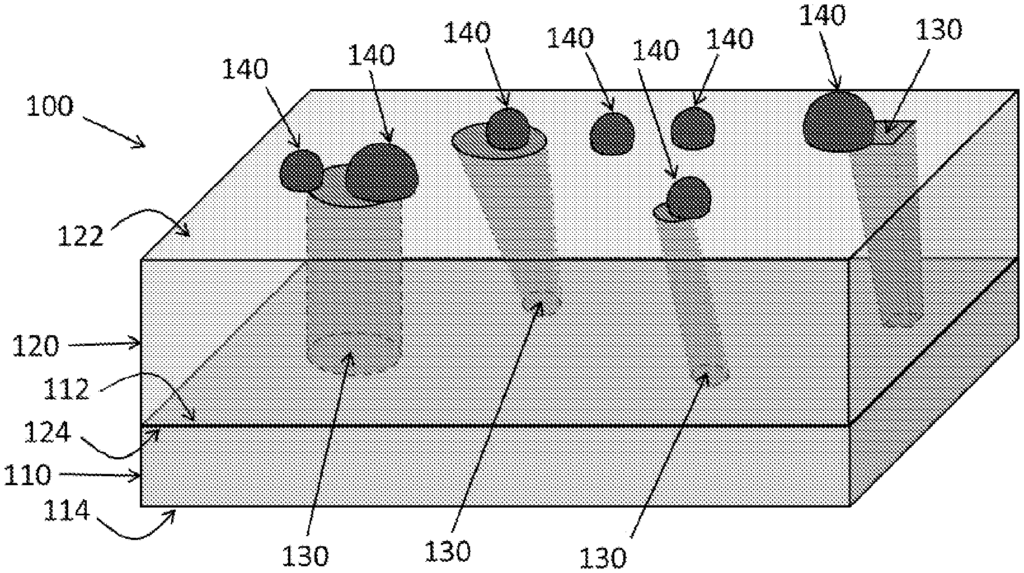

Our patented photoelectrode technology introduces a new class of materials that significantly enhance the efficiency of solar energy conversion. These photoelectrodes are designed with advanced materials that offer superior light absorption and charge separation properties, making them ideal for solar cells and other photoactive devices. The unique method of manufacturing these photoelectrodes allows for improved scalability and durability, reducing production costs while maintaining high performance.

This technology is not limited to just solar energy applications. It can be applied in areas such as photoelectrochemical water splitting, photodetectors, and other energy-harvesting devices. By improving the overall efficiency of light-driven processes, this innovation opens up new possibilities for creating more reliable and cost-effective solar power systems.

Key Benefits

- Enhanced Energy Conversion: Improves the efficiency of solar energy conversion, increasing the overall output of solar cells and energy systems.

- Durable and Scalable: The materials and methods used in this technology ensure long-term performance and scalability for large-scale applications.

- Broad Application Potential: Useful not only in solar energy but also in photodetectors and other photoactive systems.

- Cost-Effective Manufacturing: The method of making these photoelectrodes reduces production costs, making solar technologies more accessible.

A Leap Forward in Solar Energy Efficiency

Licensing this photoelectrode technology provides companies in the renewable energy sector with a powerful tool to improve solar energy capture and conversion. With its ability to enhance efficiency and reduce costs, this technology is poised to play a key role in advancing the global shift toward sustainable and clean energy solutions.

- Abstract

- Claims

Share

Title

Photoelectrodes and methods of making and use thereof

Inventor(s)

Edward T. Yu, Soonil LeeLi Ji

Assignee(s)

University of Texas System

Patent #

20240194802

Patent Date

June 13, 2024