Optimizing Light Transmission for Critical Applications

Introduction

Whether in surgical settings, telecommunications, or industrial applications, the need for highly efficient, precise, and reliable light transmission systems is constantly growing. Connecting light cables to illuminators, particularly in systems where precision and intensity matter, requires technology that ensures seamless and efficient light transfer. Our patented system is designed to optimize the connection between light cables and illuminators, offering superior performance for applications where lighting is critical.

The Gap in Current Lighting Systems

Current methods of connecting light cables to illuminators are often cumbersome and lack precision, leading to diminished light intensity, potential disconnects, and suboptimal performance. In critical environments—such as medical surgeries or optical communications—this inefficiency can have far-reaching consequences. Loss of light intensity or improper connections can disrupt procedures, delay operations, or cause costly malfunctions.

For industries relying on high-performance lighting solutions, such as healthcare, telecommunications, and manufacturing, ensuring maximum light transfer efficiency is paramount. However, current systems often fall short, leaving gaps that compromise both performance and safety.

An Innovative Connection System

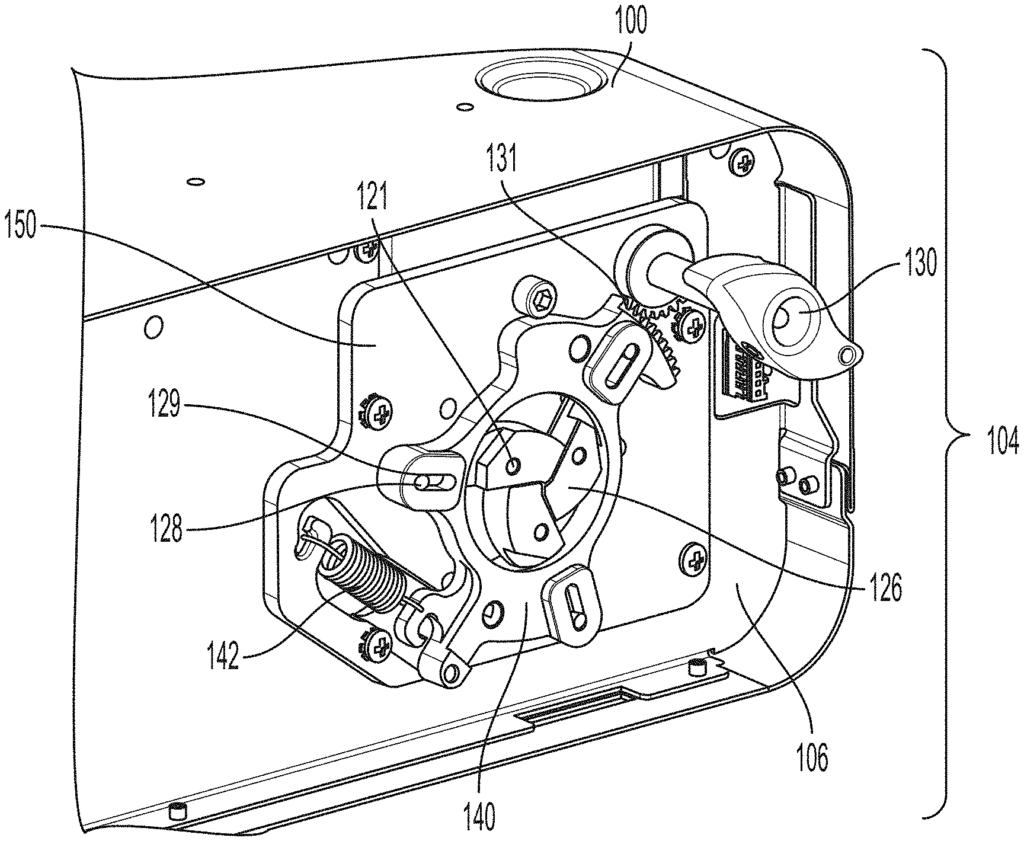

This patented system offers a comprehensive solution to address the inefficiencies and risks associated with traditional lighting connection methods. Our innovative design ensures a seamless connection between the light cable and illuminator, maximizing light transmission and minimizing loss. The system also allows for easy and secure connections, ensuring that the light cable remains firmly in place during operation, reducing the risk of disruption in critical environments.

The device is engineered for high-performance environments, from medical settings requiring intense, focused light to industrial applications where precision illumination is necessary. The versatility of this system makes it adaptable for various uses, including automotive, aerospace, and optical communication industries, where precision lighting plays an essential role.

Superior Benefits

- Maximized Light Transmission: The advanced design ensures maximum light transfer with minimal loss, enhancing performance in high-intensity, precision lighting environments.

- Secure and Reliable Connections: With an intuitive connection mechanism, this system ensures that light cables remain securely connected, reducing the risk of interruptions during critical procedures or operations.

- Versatility Across Industries: Whether for medical, optical, or industrial applications, this system is adaptable to a wide range of industries requiring efficient lighting solutions.

- Improved Workflow and Efficiency: By minimizing light loss and ensuring secure connections, this system improves overall workflow, reducing downtime and ensuring smoother operations.

The Right Solution for Modern Lighting Needs

Licensing this cutting-edge system offers your organization the opportunity to improve light transmission efficiency, optimize workflows, and provide better service in critical lighting applications. This technology can enhance performance across various industries, ensuring precision and reliability when it matters most.

- Abstract

- Claims

The invention claimed is:

1. An illuminator comprising a receptacle for connecting a light cable to an illuminator, the receptacle comprising:

22. An illuminator comprising a receptacle for connecting a light cable to an illuminator, the receptacle comprising:

34. An illuminator comprising a receptacle for connecting a light cable to an illuminator, the receptacle comprising:

35. A method for connecting a receptacle of an illuminator to a light cable, the method comprising:

Share

Title

Systems and methods for connecting a light cable to an illuminator

Inventor(s)

Wenjie Deng, Michelle SUN, Maziyar Keshtgar

Assignee(s)

Stryker Corp

Patent #

11698522

Patent Date

July 11, 2023