Precision Detection with Magnetic Field Technology

Introduction

This innovative detection system, utilizing a finely tuned magnetic field gradient, provides unparalleled accuracy in identifying materials. Designed for industries where matter detection is critical, this technology brings a fresh approach to detecting substances in complex environments, ensuring precise analysis even in challenging conditions. Its adaptable, reliable design makes it invaluable for applications ranging from medical imaging to industrial quality control, allowing organizations to expand their detection capabilities with confidence.

The Challenge: Detecting Matter in Diverse Conditions

Traditional detection systems often lack the adaptability needed to distinguish various materials in fluctuating conditions or complex environments. Whether in medical imaging or security screening, the inability to reliably detect specific substances poses risks to safety, quality, and efficiency. Standard detection methods may also fail to isolate materials accurately, resulting in inconsistencies that impact the performance and dependability of the analysis. With the growing need for precise detection across sectors, industries require an advanced solution that ensures reliable, real-time material identification.

Advanced Detection with Magnetic Field Precision

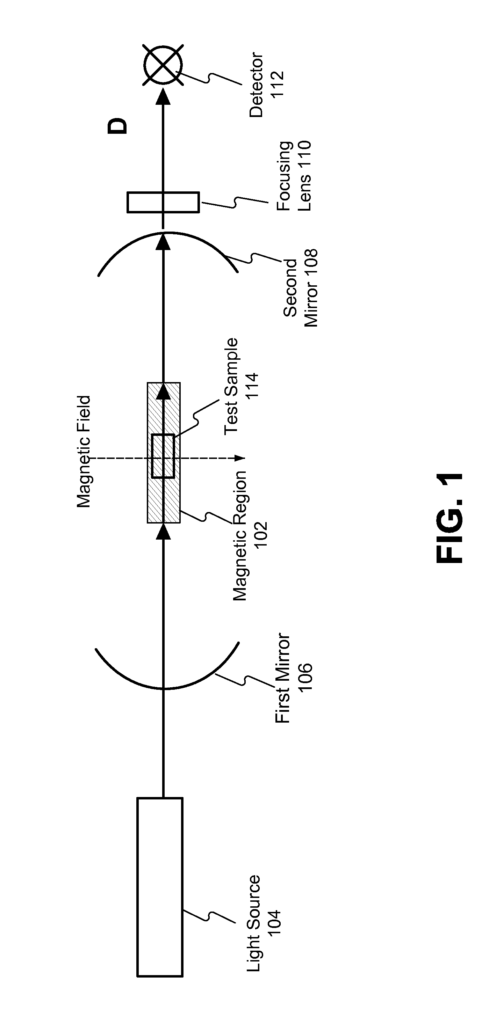

This system’s advanced method employs a magnetic field gradient, creating an environment where matter can be detected and analyzed with unparalleled accuracy. By manipulating magnetic fields to focus on specific matter signatures, the technology distinguishes between materials with high sensitivity, identifying subtle differences that conventional methods may overlook. This high-precision approach enables detection in real-time, minimizing errors and enhancing reliability. The adaptive design is suitable for diverse applications, seamlessly integrating with medical, security, industrial, and environmental systems.

Key Benefits for Leading Sectors

In medical imaging, this technology enables highly accurate diagnostics by enhancing the clarity and specificity of scans, providing healthcare providers with critical insights while improving patient outcomes. Security and defense industries benefit from enhanced screening capabilities, detecting concealed objects or substances more effectively in complex environments. For industrial applications, the system supports quality control and material verification, reducing waste and ensuring consistent product integrity. Environmental monitoring organizations can use the technology to detect pollutants or foreign substances, enabling faster response times and supporting conservation efforts. Its flexibility and precision make it an essential tool across these fields, driving operational efficiency and innovation.

Investing in Precision and Reliability

Licensing this magnetic field detection system is a strategic step for organizations focused on precision, reliability, and safety. With its sophisticated magnetic field manipulation, the system empowers users to detect matter with accuracy, supporting high-stakes applications that demand the utmost in material identification. It’s a technology tailored for industries committed to excellence in detection and analysis, providing a foundation for innovation that aligns with modern demands for safety, efficiency, and environmental responsibility.

- Abstract

- Claims

What is claimed is:

1. A method of determining material composition of a test sample, the method comprising:

3. The method of claim 1, wherein detecting birefringence in the light beam that has passed through the test sample further comprises:

5. The method of claim 1, wherein determining a material composition of the test sample based on the determined birefringence in the light beam comprises:

8. A system comprising:

20. A system for determining a test sample, the system comprising:

Share

Title

Method and Systems to Detect Matter Through Use of a Magnetic Field Gradient

Inventor(s)

Carol Y. Scarlett

Assignee(s)

Florida Agricultural and Mechanical University FAMU

Patent #

20140362378

Patent Date

December 11, 2014