Reliable Chemical Sensing with Inert Layer Protection

Introduction

This advanced chemical sensor technology offers precise and reliable detection by incorporating a patterned sensor with an inert occluding layer. This design ensures the sensor remains contamination-free, maintaining high sensitivity and accuracy in detecting chemical changes in various environments. Ideal for industries such as environmental monitoring, industrial safety, and healthcare diagnostics, this sensor technology is essential for applications where precise chemical detection is critical for safety and performance.

The Challenge: Ensuring Accurate Chemical Detection in Harsh Environments

Many chemical sensors struggle with maintaining accuracy and reliability when exposed to harsh or contaminated environments. In industrial safety and environmental monitoring, false readings or sensor degradation due to contamination can have serious consequences. The need for sensors that not only detect minute chemical changes but also withstand adverse conditions is growing across multiple industries. Current sensor technologies often lack the robustness required for long-term use in such environments, leading to higher maintenance costs and potential safety risks.

Inert Layer for Reliable and Durable Sensing

This patterned chemical sensor technology addresses these challenges by introducing an inert occluding layer that shields the sensor from environmental contaminants, ensuring reliable and accurate readings over time. The inert layer acts as a barrier, protecting the sensor’s sensitive components from interference while allowing the detection of targeted chemical substances. This durability extends the sensor’s lifespan and reduces the need for frequent maintenance or replacement. Whether monitoring air quality, detecting hazardous substances in industrial settings, or ensuring accurate diagnostic results in healthcare, this sensor’s reliability offers peace of mind to users across industries.

Key Benefits for Multiple Industries

For environmental monitoring, this sensor enables precise detection of pollutants or harmful chemicals in air, water, or soil, helping to ensure compliance with safety standards and environmental regulations. In healthcare diagnostics, the sensor’s sensitivity and durability allow for more accurate detection of biomarkers, supporting early diagnosis and treatment in critical care situations. Industrial safety applications benefit from its ability to detect hazardous gases or chemicals with high precision, reducing the risk of accidents and ensuring worker safety. Biotechnology and research fields can leverage this sensor technology to enhance chemical analyses and experimental accuracy.

Investing in Precision and Durability

Licensing this reliable chemical sensing technology provides your organization with a competitive advantage in offering durable, high-performance sensors that maintain accuracy in challenging environments. This technology represents an essential tool for industries that rely on precise chemical detection for safety, compliance, and performance. By incorporating this innovative sensor into your product line, your company can deliver trusted solutions that meet the growing demand for reliable, contamination-free chemical sensing across various sectors. It’s an investment in innovation, accuracy, and long-term reliability for critical applications.

- Abstract

- Claims

What is claimed is:

1. A sensor that detects a chemical, the sensor comprising:

a film that includes a film body that is responsive to the presence of a chemical by providing a color change and that comprises:

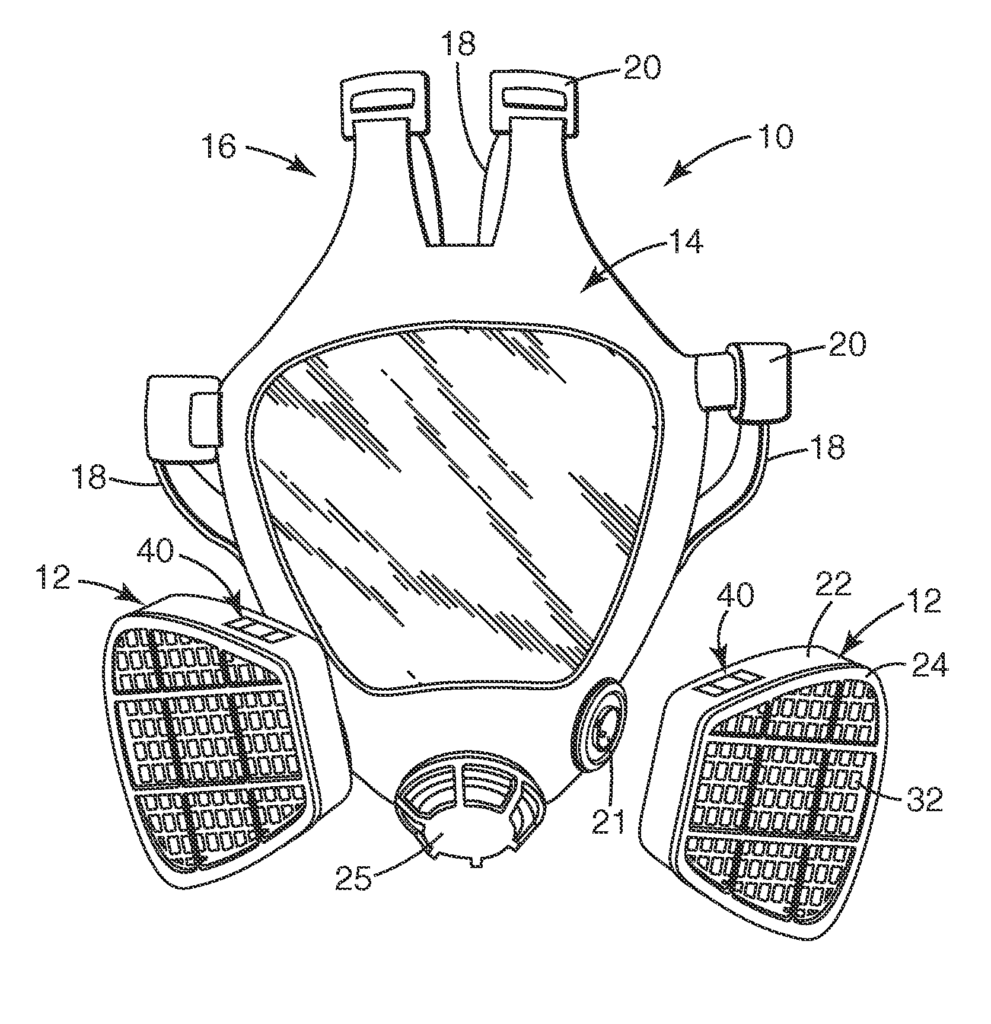

18. A filter cartridge that comprises:

Share

Title

Patterned chemical sensor having inert occluding layer

Inventor(s)

Neal A. Rakow, Thomas W. Holmquist-Brown, Brian L. Linzie, John C. Hulteen, Duane D. Fansler, Richard J. Poirier, Vivek Bharti

Assignee(s)

3M Innovative Properties Co

Patent #

8955515

Patent Date

February 17, 2015