Revolutionize Battery Research and Development with In-Situ NMR Spectroscopy Technology

Introduction

In the rapidly evolving field of energy storage, metal-air and metal-free air batteries are gaining attention for their potential to deliver higher energy densities and longer lifespans compared to traditional battery technologies. However, the development and optimization of these batteries pose significant challenges, particularly in understanding the complex electrochemical reactions that occur during operation. Our patented “Apparatus for In-Situ NMR Spectroscopy of Metal-Air and Metal-Free Air Batteries” (Patent #10126366) provides a breakthrough solution, offering unparalleled insights into battery behavior and performance.

The Challenge

Metal-air and metal-free air batteries have the potential to revolutionize energy storage, but their commercialization has been hindered by a lack of understanding of the intricate chemical processes involved in their operation. Traditional analytical methods fall short in providing real-time, detailed data on the internal workings of these batteries, making it difficult to optimize their design and performance. Without this critical information, it’s challenging to address issues like degradation, efficiency losses, and overall stability.

The Solution

Our patented apparatus enables in-situ Nuclear Magnetic Resonance (NMR) spectroscopy, allowing researchers and engineers to observe and analyze the electrochemical processes within metal-air and metal-free air batteries as they occur. This technology offers several compelling advantages:

- Real-Time, Non-Destructive Analysis: Unlike other methods that require disassembly or post-mortem analysis of batteries, this apparatus allows for real-time observation of chemical reactions inside a fully operational battery. This non-destructive approach preserves the integrity of the battery while providing continuous data, enabling a deeper understanding of its performance under various conditions.

- Unparalleled Insight into Battery Chemistry: NMR spectroscopy provides detailed information about the chemical environment inside the battery, including the identification of intermediates and reaction products. This insight is crucial for understanding the mechanisms of charge and discharge processes, electrolyte interactions, and the formation of by-products that can affect battery efficiency and lifespan.

- Accelerated Development and Optimization: By using this in-situ NMR technology, researchers can rapidly test and iterate on battery designs, materials, and electrolytes. The ability to monitor changes in real-time allows for quicker identification of performance issues and the effects of different variables, significantly speeding up the R&D process.

- Enhanced Battery Performance and Longevity: With the detailed data provided by this technology, it becomes possible to make informed decisions about materials and designs that enhance battery performance, stability, and longevity. This leads to the development of more reliable and efficient batteries, which is critical for applications in electric vehicles, renewable energy storage, and portable electronics.

- Competitive Advantage in a Growing Market: The demand for advanced battery technologies is increasing rapidly across multiple industries. By licensing this patented apparatus, your company gains a powerful tool that can set you apart from competitors. The ability to offer optimized, high-performance batteries can open new market opportunities and establish your brand as a leader in the energy storage sector.

The Opportunity

In an industry where innovation is key to staying ahead, licensing our patented “Apparatus for In-Situ NMR Spectroscopy of Metal-Air and Metal-Free Air Batteries” gives you access to a cutting-edge technology that can transform your research and development capabilities. This apparatus is not just a tool for observation; it’s a gateway to pioneering new battery technologies that can meet the growing demand for efficient, durable, and high-energy-density storage solutions.

Don’t miss the chance to lead the next wave of battery innovation. License this technology today and unlock the full potential of metal-air and metal-free air batteries.

- Abstract

- Claims

We claim:

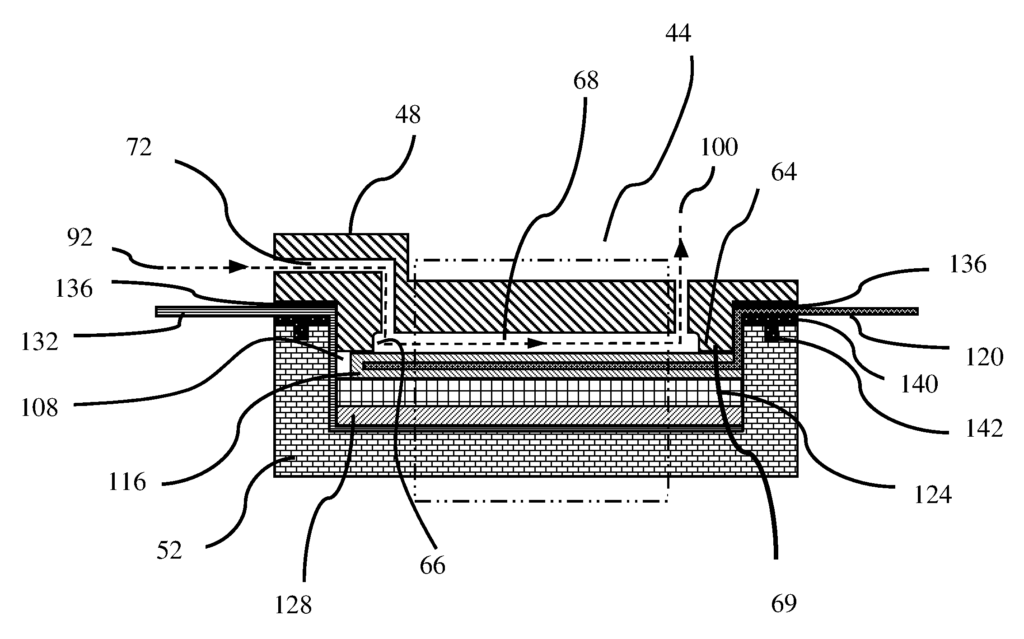

1. An apparatus for the in situ NMR monitoring of a battery comprising an anode and an air cathode during cycling of the cell, the apparatus comprising:

8. An apparatus for the in situ NMR monitoring of a battery comprising an anode and an air cathode, the apparatus comprising:

10. An apparatus for the in situ NMR monitoring of a battery comprising an anode and an air cathode, the apparatus comprising:

sealing structure for hermetically sealing the anode container portion and the cathode container portion; and,

11. A method of evaluating an air cathode battery in situ during cycling of the cell, comprising the steps of:

15. A battery assembly for the in situ NMR spectroscopy of an air cathode battery comprising:

Share

Title

Apparatus for in-situ NMR spectroscopy of metal-air and metal-free air batteries

Inventor(s)

Jian-Ping Zheng, Annadanesh Shellikeri

Assignee(s)

Florida State University Research Foundation Inc

Patent #

10126366

Patent Date

November 13, 2018