Accelerate Precision: Transform Material Testing with Our Innovative Tensile Test Fixture

Introduction

In the fast-paced world of material science and engineering, efficiency and accuracy are paramount. Our patented “Tensile Test Fixture for Quick Testing of Materials with Low Transverse Strength” (Patent #11543335) is a game-changer designed to streamline your testing process, providing you with reliable data faster than ever before.

The Challenge

In many industries, materials with low transverse strength, such as composites, thin films, and other advanced materials, are becoming increasingly prevalent due to their unique properties and applications. However, testing these materials for tensile strength poses significant challenges. Traditional tensile testing methods can be time-consuming, labor-intensive, and often yield inconsistent results, especially when dealing with materials that are prone to premature failure or require delicate handling.

The Solution

Our patented tensile test fixture addresses these challenges head-on, offering a robust and innovative solution that transforms how materials with low transverse strength are tested. Here’s why you should consider licensing this cutting-edge technology:

-

Rapid and Reliable Testing: This fixture is designed for quick setup and execution, dramatically reducing the time required to prepare and conduct tensile tests. With its user-friendly design, you can streamline your testing process, allowing for more tests in less time without compromising accuracy.

-

Enhanced Accuracy and Consistency: One of the biggest challenges in testing materials with low transverse strength is avoiding premature failure or inconsistent results. Our fixture ensures uniform load application and minimizes stress concentrations, leading to more accurate and reliable data. This level of precision is crucial for industries where material performance is critical, such as aerospace, automotive, and electronics.

-

Versatility Across Materials: This fixture is not limited to a single type of material. Its adaptable design allows it to be used with a wide range of materials, including composites, films, textiles, and other low-strength materials. This versatility makes it a valuable addition to any testing lab, providing a comprehensive solution for diverse testing needs.

-

Cost-Effective and Efficient: By reducing the time and labor required for material testing, this fixture offers significant cost savings. The quick setup and testing process mean less downtime and more productivity, allowing your team to focus on analysis and innovation rather than cumbersome testing procedures.

-

Market Differentiation: Licensing this technology gives your company a competitive edge. By incorporating this advanced testing fixture into your operations, you can ensure higher quality standards, faster time-to-market for new materials, and enhanced credibility with clients and stakeholders.

The Opportunity

In today’s competitive landscape, where materials are being pushed to their limits in terms of performance and reliability, having a superior testing method is not just an advantage—it’s a necessity. By licensing our patented tensile test fixture, you’re investing in a tool that will enhance your testing capabilities, improve your material development process, and ultimately, give you a distinct edge in the marketplace.

Don’t miss this opportunity to revolutionize your material testing procedures. License our tensile test fixture today and take the first step towards faster, more accurate, and reliable material testing.

- Abstract

- Claims

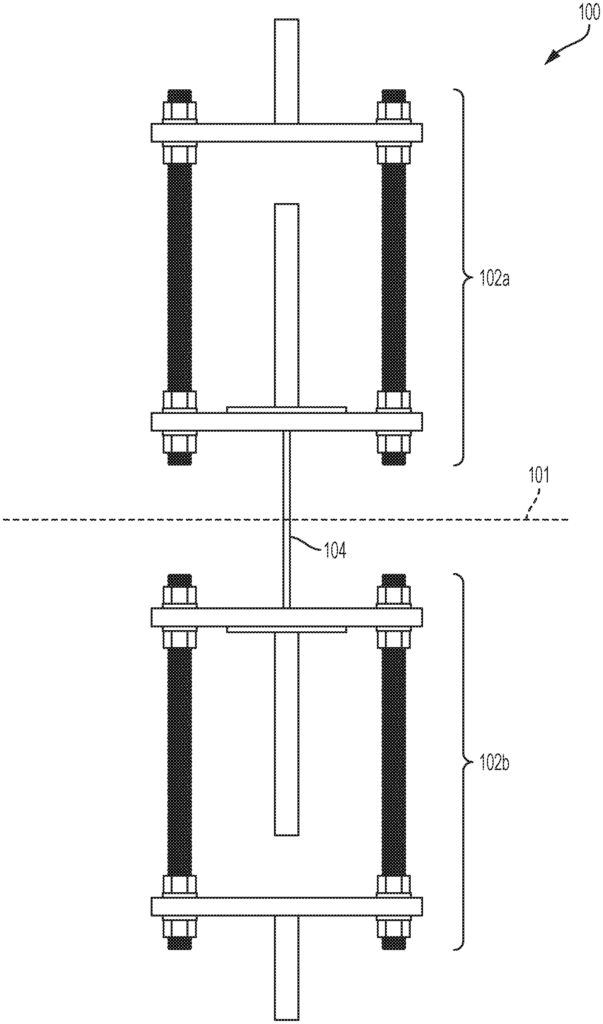

A tensile test fixture for quick testing of materials with low transverse strength and relatively high longitudinal strength. After the tensile test fixture is loaded into a universal testing machine, such as a two-part load frame, a first test specimen is aligned and tensile tested. Alignment of the first test specimen ensures that all consecutive test specimens are aligned within the tensile test fixture without further alignment required.

What is claimed is:

1. A tensile test fixture for testing materials with low transverse strength, the test fixture comprising:

8. A method of to tensile testing materials with low transverse strength, the method comprising:

providing an upper fixture and a lower fixture, each fixture comprising:

Share

Title

Tensile test fixture for quick testing of materials with low transverse strength

Inventor(s)

Raphael Kampmann

Assignee(s)

THE FLORIDA STATE UNIVERSITY RESEARCH FOUNDATION INC

Patent #

11543335

Patent Date

January 3, 2023