Push the Boundaries of Performance with Nanoparticle-Reinforced Composites

Introduction

In the competitive world of advanced materials, staying ahead means pushing the boundaries of what’s possible. Our patented “Nanoparticle-Reinforced Composites and Methods of Manufacture and Use” (Patent #10,214,801) offers you a chance to do just that—unlocking new levels of performance, durability, and versatility that can redefine industries.

The Challenge

Modern manufacturing demands materials that are stronger, lighter, and more adaptable than ever before. Traditional composites have served well, but they often face limitations when extreme conditions or specific applications require more. Whether you’re in aerospace, automotive, consumer electronics, or any industry relying on high-performance materials, finding a solution that enhances product capabilities without adding significant weight or cost is critical.

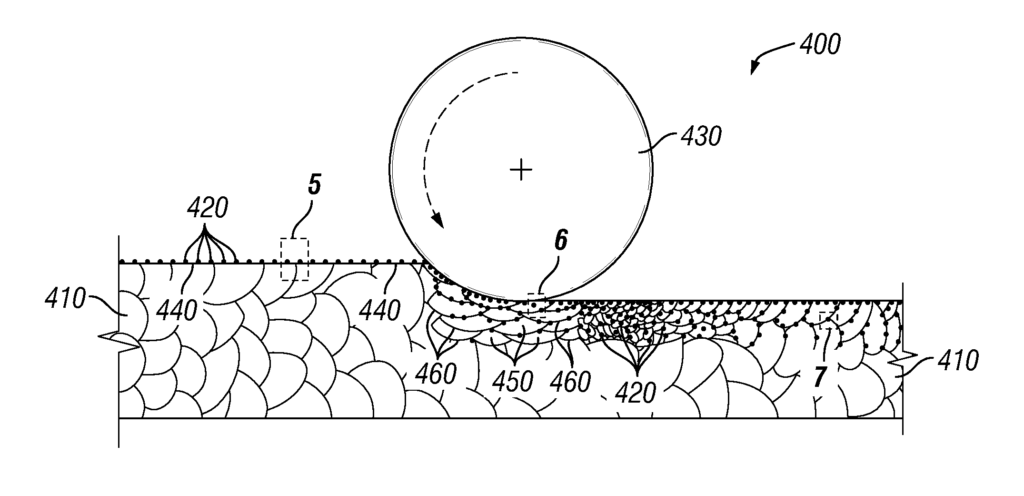

The Solution

This patent introduces a breakthrough in composite material technology by integrating nanoparticles into the matrix. These nanoparticles are not just fillers—they actively reinforce the composite, resulting in a material with significantly enhanced properties. Here’s why licensing this technology is a game-changing move for your business:

- Superior Strength and Durability: Nanoparticles provide extraordinary reinforcement at the molecular level, creating composites that are far stronger and more durable than traditional materials. This results in products that can withstand higher stress, offer longer lifespans, and perform reliably in extreme environments.

- Lightweight Innovation: One of the greatest advantages of nanoparticle-reinforced composites is their ability to maintain or even reduce weight while enhancing strength. This is crucial for industries like aerospace and automotive, where every gram counts in improving efficiency and performance.

- Versatile Applications: The potential uses for these composites are vast. From structural components in vehicles and aircraft to consumer electronics housings, medical devices, and even sports equipment, this material can be tailored to meet the unique demands of various industries, providing a competitive edge in multiple markets.

- Efficient Manufacturing Process: Our patented methods ensure that these advanced composites can be manufactured at scale, with consistent quality and cost-effectiveness. This scalability makes it easier to integrate this technology into existing production lines without significant overhauls or delays.

The Opportunity

By licensing our nanoparticle-reinforced composite technology, you’re not just acquiring a material—you’re embracing a new era of product innovation. This patent offers the unique ability to enhance your product offerings, differentiate your brand, and meet the evolving demands of modern consumers and industries.

Don’t settle for the status quo. Take the leap into the future of materials science and empower your products with unmatched strength, lightweight performance, and versatility. License this technology today and start building the future.

- Abstract

- Claims

I claim:

1. A method for forming a composite structure, the method comprising:

Share

Title

Nanoparticle-reinforced composites and methods of manufacture and use

Inventor(s)

Chengying Xu

Assignee(s)

Florida State University Research Foundation Inc

Patent #

10214801

Patent Date

February 26, 2019