Elevate Your Materials with Functionalized Carbon Nanotubes: The Next Frontier in Innovation

Introduction

In the world of advanced materials, the stakes are high. Industries demand materials that are stronger, lighter, more conductive, and adaptable to a wide range of applications. Our patented “Functionalized Carbon Nanotubes and Methods” (Patent #10,906,813) offers a breakthrough solution that not only meets these demands but surpasses them, opening up new possibilities across multiple industries.

The Innovation

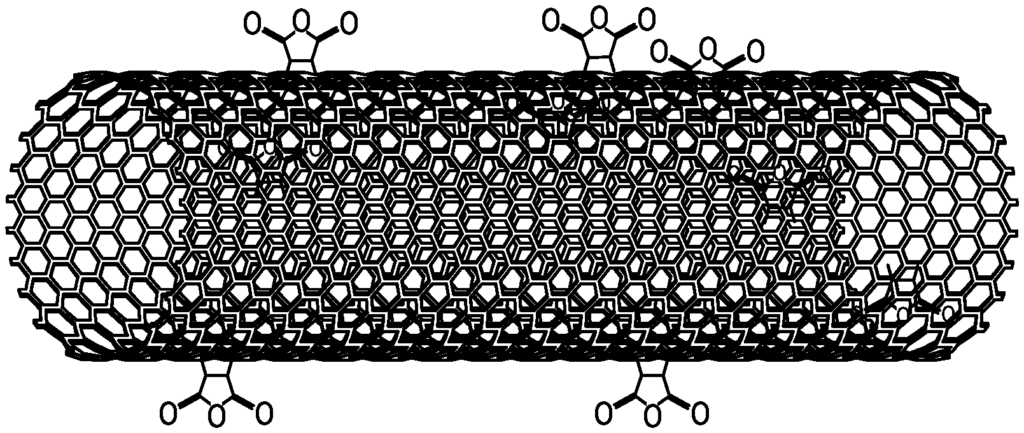

Carbon nanotubes (CNTs) are already known for their remarkable properties—exceptional strength, electrical conductivity, and thermal stability. But the true potential of CNTs lies in their functionalization. Our patent introduces a cutting-edge method to functionalize carbon nanotubes, enhancing their compatibility with other materials and significantly broadening their application scope.

Why This Technology Matters

- Unmatched Material Enhancement: Functionalized CNTs can be seamlessly integrated into polymers, metals, and ceramics, resulting in composite materials that are lighter, stronger, and more resilient. Imagine creating aerospace components that are as strong as steel but weigh a fraction of traditional materials, or automotive parts that boost fuel efficiency without sacrificing safety.

- Revolutionizing Electronics: In the realm of electronics, functionalized CNTs offer superior electrical conductivity, enabling the development of faster, more efficient circuits and components. This technology can lead to smaller, more powerful electronic devices, enhancing everything from smartphones to advanced computing systems.

- Expanding the Possibilities in Energy: For energy storage and generation, functionalized CNTs can be a game-changer. They provide the perfect platform for developing high-capacity batteries, supercapacitors, and even next-generation solar cells. The potential to store more energy in smaller spaces and convert it more efficiently could revolutionize renewable energy technologies.

- Versatility Across Industries: The potential applications of functionalized CNTs are vast and varied. Whether it’s in medical devices, where biocompatibility and strength are crucial, or in sports equipment, where lightweight yet durable materials are in demand, this technology offers a solution that can be tailored to meet the specific needs of diverse markets.

Why You Should License This Patent

By licensing this patent, you’re not just gaining access to a superior material—you’re positioning your company at the forefront of material science innovation. Functionalized CNTs offer the unique combination of cutting-edge technology with practical, scalable applications. This means you can develop products that not only outperform competitors but also set new standards in your industry.

The Opportunity

The future of material science is here, and it’s more adaptable, more efficient, and more powerful than ever before. With our functionalized carbon nanotube technology, you have the opportunity to lead in your market, driving innovation and delivering unmatched value to your customers.

Don’t just keep up with the competition—leap ahead of it. License this technology and start transforming what’s possible today.

- Abstract

- Claims

We claim:

1. A method of functionalizing a carbon nanotube, the method comprising:

18. A method of making a sensor, the method comprising:

21. A sensor comprising:

Share

Title

Functionalized carbon nanotubes and methods

Inventor(s)

Changchun Zeng, Yan Li, Zhiyong Liang

Assignee(s)

Florida State University Research Foundation Inc

Patent #

10906813

Patent Date

February 2, 2021