Precision Engineering with 3D Printed Micro Channel Plates

Introduction

In industries where precision, customization, and high-performance materials are essential, micro channel plates (MCPs) are widely used for applications such as imaging, detection, and fluid dynamics. Traditional methods of manufacturing MCPs, while effective, can be limited in terms of design flexibility, scalability, and customization for specialized tasks. Our patented 3D printing method for creating micro channel plates introduces a groundbreaking solution that combines the versatility of additive manufacturing with the precision required for advanced microstructures.

Limitations of Traditional MCP Manufacturing

Micro channel plates are key components in a variety of high-tech applications, including electron detectors, photomultipliers, and microfluidic devices. However, conventional manufacturing techniques often involve costly, time-intensive processes that limit the ability to create customized designs or prototypes quickly. Furthermore, these methods can restrict innovation due to the challenges of producing complex geometries or altering existing MCP designs to suit specific applications.

For industries requiring high-performance components, the ability to rapidly prototype and customize MCPs to meet specific needs is critical to maintaining a competitive edge.

A 3D Printed Solution for Micro Channel Plates

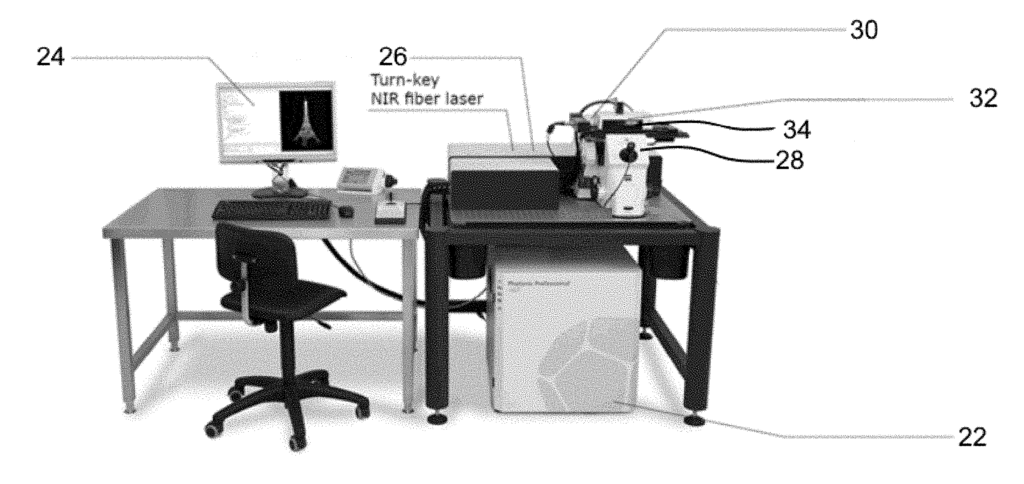

Our patented 3D printing process for micro channel plates offers an innovative solution that allows for rapid prototyping, customization, and production of intricate microstructures. Using advanced 3D printing techniques, manufacturers can create MCPs with precise channel configurations, customized designs, and complex geometries that are difficult or impossible to achieve using traditional manufacturing methods. This process allows for faster turnaround times, making it ideal for both research and commercial applications that demand flexibility and innovation.

The use of 3D printing also opens new possibilities for producing MCPs that are tailored to specific fluidic or electronic properties, making it a versatile tool for a wide range of applications, including microfluidics, particle detection, and image intensification. The ability to design and print MCPs on-demand reduces lead times, lowers production costs, and provides greater control over the final product.

Key Benefits

- Customization: Design and print MCPs with complex geometries tailored to specific needs.

- Rapid Prototyping: Quickly develop and iterate designs for research or commercial use.

- Cost-Effective: Lower production costs through additive manufacturing compared to traditional methods.

- Versatile Applications: Suitable for use in biotechnology, microfluidics, and advanced imaging technologies.

Advancing Precision Engineering with 3D Printing

Licensing this 3D printed micro channel plate technology offers manufacturers and researchers a flexible, cost-effective solution for creating high-performance MCPs. By embracing this innovative process, businesses can meet the growing demand for customized, precision-engineered components across a range of industries.

- Abstract

- Claims

Share

Title

3d printed micro channel plate, method of making and using 3d printed micro channel plate

Inventor(s)

Robert G. Wagner, Michael J. Pellin, Howard Nicholson, Lei XiaJingbo Wang, Junqi Xie, Anil U. Mane, Jeffrey W. Elam

Assignee(s)

UChicago Argonne LLC

Patent #

20190318896

Patent Date

October 17, 2019