Empower Connectivity with Aerogel Antenna Innovation

Introduction

As the demand for efficient, lightweight, and high-performance communication systems grows across industries, finding advanced materials that enhance antenna performance has become crucial. Aerogels, known for their extremely low density and excellent thermal and electrical properties, offer a unique solution in the development of next-generation antennas. Our patented aerogel-based antennas combine these extraordinary material properties with cutting-edge design, creating a versatile solution for communication needs in aerospace, telecommunications, defense, and more. Whether for satellites, aircraft, or terrestrial communication networks, this technology offers superior performance with reduced weight, making it ideal for applications where weight, strength, and performance are paramount.

Limitations of Conventional Antennas

In aerospace, telecommunications, and military applications, antennas are critical for ensuring reliable communication and data transmission. However, traditional antenna materials can be heavy and bulky, which is a significant disadvantage, particularly in aerospace and satellite applications where weight is a key concern. Additionally, antennas must perform well across various frequencies and environmental conditions, requiring materials that are both durable and highly efficient.

For industries that rely on advanced communication systems, such as satellite operators, aviation companies, and military organizations, there is a pressing need for antennas that offer high performance without the added weight and bulk of conventional designs. This need is particularly acute in space and aviation, where every ounce of weight impacts fuel efficiency, payload, and overall mission success.

Aerogel-Based Antennas: The Next Step in Communication Technology

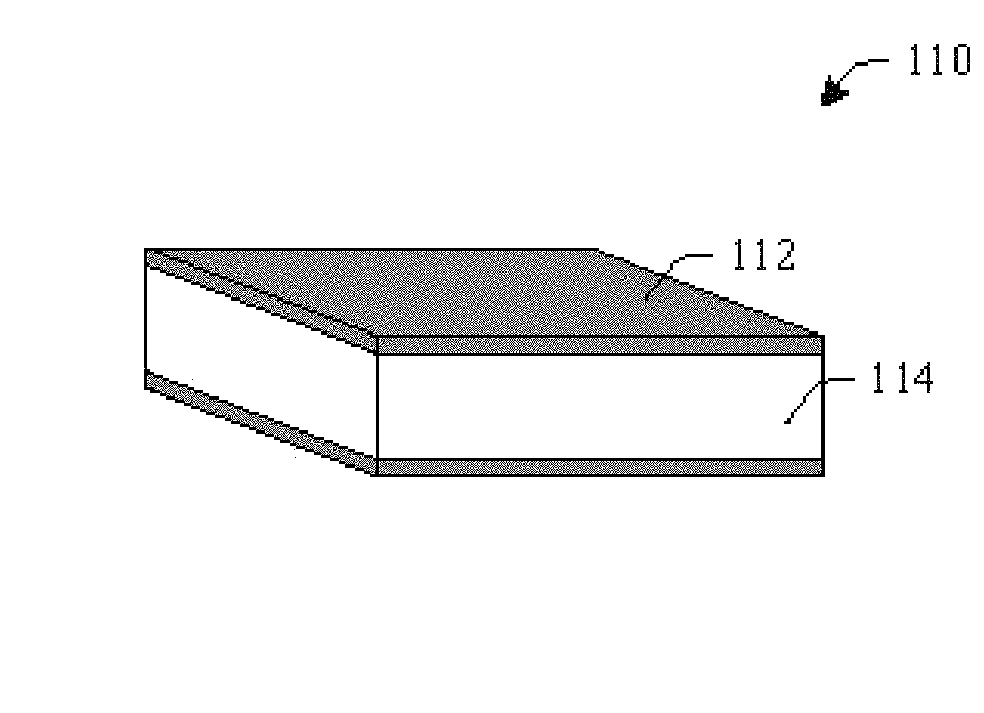

Our patented aerogel-based antenna technology provides a game-changing solution by combining the unique properties of aerogel materials with state-of-the-art antenna design. Aerogels are among the lightest solid materials known, offering exceptional thermal and electrical insulation while maintaining structural integrity. These properties make them an ideal material for antennas, which require high strength, minimal weight, and excellent signal transmission capabilities.

The use of aerogels allows for the creation of antennas that are not only lighter but also more efficient than traditional designs. This results in antennas that are easier to deploy and less demanding in terms of structural support, particularly in aerospace and satellite applications. Moreover, the thermal and electrical properties of aerogels enable antennas to perform exceptionally well across a wide range of frequencies and environmental conditions, making them suitable for use in harsh environments, such as outer space or high-altitude aviation.

Key Benefits

- Lightweight Design: Reduces the overall weight of communication systems, especially in aerospace and satellite applications.

- High Performance: Aerogels provide superior signal transmission and reception capabilities across multiple frequencies.

- Durability in Extreme Conditions: Ideal for use in challenging environments, including space, high altitudes, and military applications.

- Versatile Application: Suitable for aerospace, telecommunications, and defense, with adaptability to various communication needs.

Unlocking Superior Communication with Aerogel-Based Antennas

Licensing this aerogel-based antenna technology offers companies in aerospace, telecommunications, and defense the opportunity to leverage lightweight, high-performance communication solutions. By integrating aerogel materials into antenna design, businesses can enhance the efficiency, durability, and adaptability of their communication systems, meeting the needs of modern and future applications.

- Abstract

- Claims

What is claimed is:

1. An antenna comprising:

16. A method for making an antenna comprising:

Share

Title

Aerogel-based antennas for aerospace and terrestrial applications

Inventor(s)

Mary Ann B. Meador, Felix A. Miranda, Frederick W. Van Keuls

Assignee(s)

National Aeronautics and Space Administration NASA

Patent #

10446920

Patent Date

October 15, 2019