Empower Cellular Growth with Advanced Scaffolds

Introduction

The field of cell culture and tissue engineering is advancing rapidly, with increasing demand for more efficient, scalable, and reliable methods of growing mammalian cells. Our patented microcarriers, matrices, and scaffolds provide an innovative solution for supporting cell growth and differentiation, offering unmatched versatility for biomanufacturing, regenerative medicine, and drug development. With a focus on efficiency, biocompatibility, and performance, this technology helps overcome the current limitations of conventional cell culture methods, empowering industries to take their cellular research and production to the next level.

Barriers in Cell Culture and Tissue Engineering

Scaling up the production of mammalian cells for research, therapy, or pharmaceutical applications has historically presented numerous challenges. Traditional cell culture methods often require significant space, time, and resources, while limiting the ability to control the growth environment. In tissue engineering, building scaffolds that can support cellular differentiation and tissue formation is essential for advancing regenerative medicine, yet conventional options often lack the ability to mimic natural cellular environments.

Both fields are seeking more efficient and reliable methods to improve cell yields and promote more consistent cellular behavior, while simultaneously scaling the production of high-quality cells for therapeutic applications.

Why Choose Advanced Cellular Growth Scaffolds?

Our patented technology offers an elegant solution through microcarriers, matrices, and scaffolds that are designed for optimal mammalian cell culture. These materials provide a superior environment for cell attachment, growth, and differentiation, allowing for more efficient cell expansion and tissue formation. Whether used in bioreactors for mass production or in tissue engineering for regenerative medicine, these scaffolds enhance the overall process, yielding better results with less resource investment.

The biocompatibility of these scaffolds ensures they are safe for use in medical applications, while their structure mimics the natural extracellular matrix, promoting more realistic cellular growth and behavior. These microcarriers are designed to facilitate large-scale cell culture in a variety of applications, making them ideal for biopharma companies, research labs, and tissue engineers alike.

Key Benefits

- Enhanced Cell Growth: Provides optimal conditions for mammalian cell attachment, expansion, and differentiation.

- Scalable Production: Ideal for large-scale biomanufacturing, improving efficiency in cell culture processes.

- Biocompatible and Versatile: Suitable for use in regenerative medicine, drug development, and tissue engineering.

- Advanced Tissue Engineering: Supports realistic tissue formation with scaffolds that mimic natural cellular environments.

Fuel Breakthroughs with Advanced Cellular Growth Scaffolds

Licensing this cutting-edge scaffold technology offers companies a powerful tool to enhance cell culture, improve tissue engineering outcomes, and streamline biomanufacturing. With its combination of biocompatibility, scalability, and performance, this technology unlocks new possibilities for breakthroughs in biotechnology and regenerative medicine.

- Abstract

- Claims

What is claimed is:

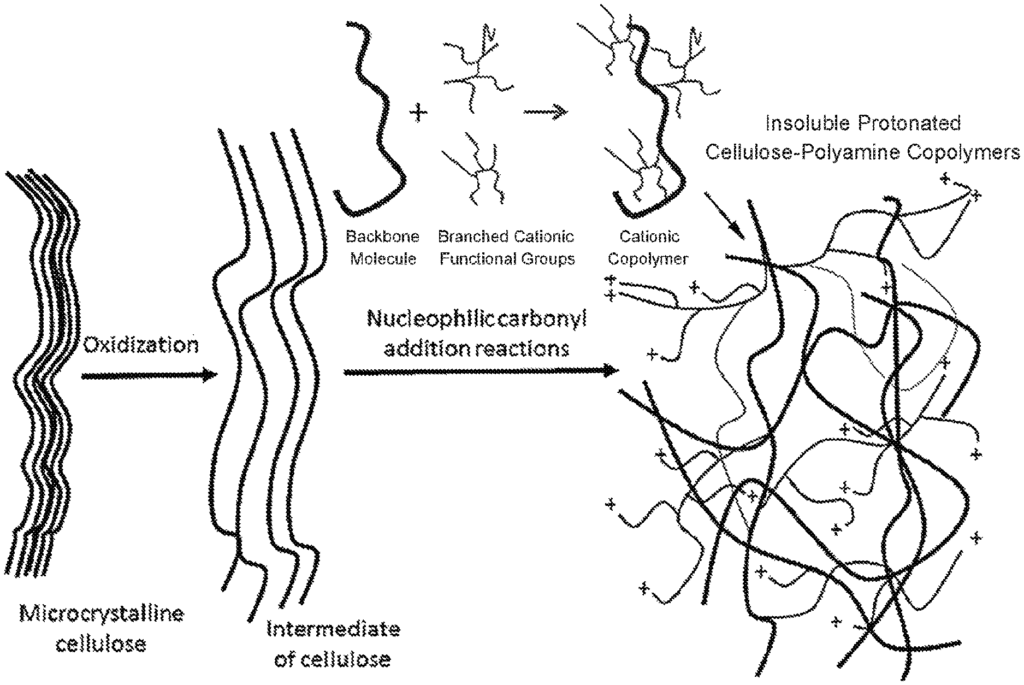

1. Polysaccharide-polyamine copolymer or glycoprotein-polyamine copolymers having an amino functionality which will provide a cationic copolymeric material having a three-dimensional structure with cationic sites when protonated, the polysaccharide-polyamine copolymer comprising:

2. A method of producing the polysaccharide-polyamine copolymers or glycoprotein-polyamine copolymers according to claim 1, the method comprising the steps of:

17. Polysaccharide-polyamine copolymer or glycoprotein-polyamine copolymers having an amino functionality which will provide a cationic copolymeric material having a three-dimensional structure with cationic sites when protonated, the polysaccharide-polyamine copolymer comprising:

Share

Title

Microcarriers, matrices and scaffolds for culturing mammalian cells and methods of manufacture

Inventor(s)

James W. Mitchell, Dazhi Yang

Assignee(s)

Howard University

Patent #

10723809

Patent Date

July 28, 2020