Efficient Reservoir System for Spray Guns

Introduction

This innovative reservoir system for hand-held spray guns provides a powerful solution for industries where precision and efficiency are critical. Whether used in automotive painting, industrial coatings, or home improvement projects, this system enhances the overall performance of spray guns by improving fluid delivery, reducing waste, and ensuring greater control. For companies looking to offer high-performance spray tools, this technology represents an opportunity to meet the growing demand for precision, quality, and operational efficiency in spray applications.

The Challenge: Fluid Control and Waste Reduction in Spray Systems

One of the major challenges in spray applications is managing fluid flow to ensure precision and minimize waste. Traditional reservoir systems often struggle to maintain consistent fluid delivery, leading to overspray, uneven coating, or wasted material. This inefficiency can increase costs, require more frequent refills, and reduce the quality of the finished product. Additionally, many spray gun systems can be cumbersome, making it difficult for operators to manage multiple tasks effectively. There is a growing need for a solution that addresses these issues while providing a seamless, easy-to-use design.

Advanced Reservoir System for Optimal Performance

This reservoir system solves these challenges by delivering a streamlined solution that optimizes fluid control and enhances the precision of spray applications. The system is designed to maintain consistent pressure and fluid flow, ensuring even coverage and reducing material waste. Its innovative structure allows for easy refill and handling, making it user-friendly and efficient. Whether used for large-scale industrial applications or detailed painting projects, this system offers flexibility and performance that elevate the quality and speed of spray operations.

Key Benefits for Multiple Sectors

In manufacturing and automotive industries, this reservoir system improves the efficiency of spray painting and coating processes, reducing material waste and enhancing product quality. Industrial coatings companies can benefit from the system’s ability to deliver consistent results, improving both performance and cost-efficiency. Home improvement and DIY markets will appreciate the system’s ease of use, offering a tool that simplifies projects while delivering professional-level results. Additionally, the reservoir system’s adaptability makes it a valuable tool for both professional contractors and consumers, broadening its market appeal.

Investing in Enhanced Spray Technology

Licensing this efficient reservoir system technology positions your company to meet the increasing demand for high-performance spray applications across various industries. By offering a tool that reduces waste, enhances precision, and improves ease of use, your business can provide a solution that delivers tangible value to professionals and consumers alike. This technology represents a forward-thinking approach to spray gun design, providing a more efficient and effective tool for those seeking precision in their work. It’s an investment in quality, performance, and customer satisfaction, offering a competitive edge in the spray tool market.

- Abstract

- Claims

What is claimed is:

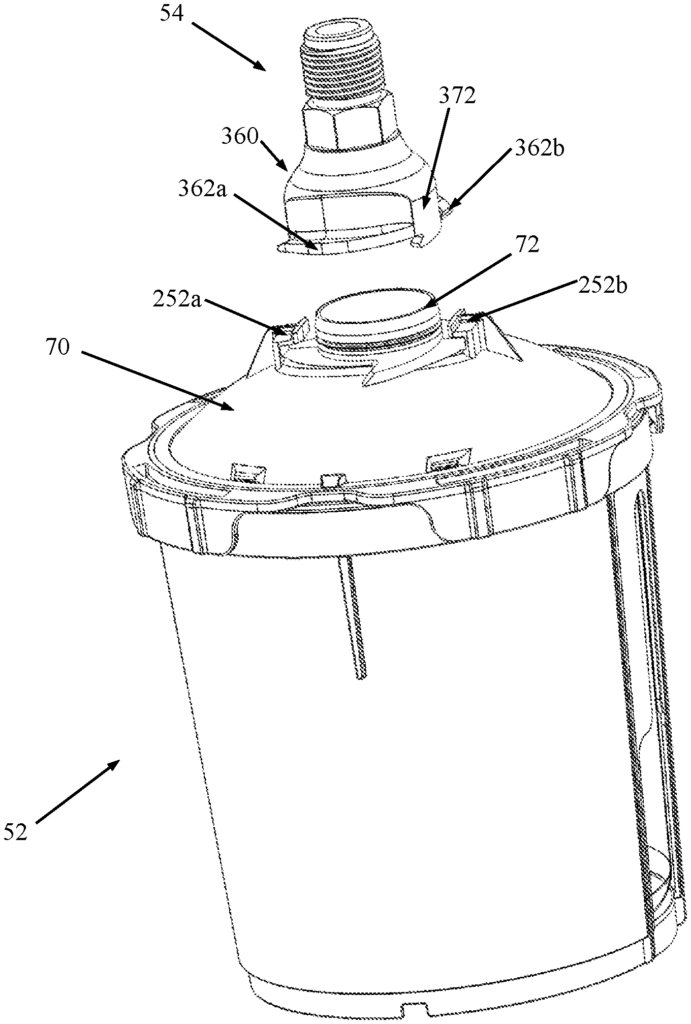

1. A lid for a spray gun reservoir system comprising:

a lid body comprising:

8. A lid for a spray gun reservoir system comprising:

14. A reservoir system for use with a spray gun, the system comprising:

a lid including:

Share

Title

Reservoir systems for hand-held spray guns and methods of use

Inventor(s)

Anna M. Hegdahl, Alexander T. Ebertowski, Scott D. Gullicks, Andrew R. Henry, Stephen C. P. Joseph, Sabeel Ullah

Assignee(s)

3M Innovative Properties Co

Patent #

10689165

Patent Date

June 23, 2020