Precision Masking for Flawless Surface Protection

Introduction

This advanced masking article and method offer a solution for industries that require precise and efficient surface masking, particularly in automotive, manufacturing, and industrial painting processes. The technology ensures that substrates are effectively masked, allowing for flawless application of coatings or finishes without contamination. For companies seeking to improve their painting and coating processes, this technology provides the reliability and precision needed to achieve professional results while enhancing productivity.

The Challenge: Inconsistent Masking and Surface Contamination

Masking is a critical step in many industrial processes, but traditional masking methods can often lead to inefficiencies. Incorrectly applied masking materials can result in overspray, uneven edges, or contamination of surfaces that require protection. This not only compromises the quality of the finished product but also leads to rework, wasted materials, and increased labor costs. With industries placing greater emphasis on high-quality finishes and streamlined operations, the demand for a more reliable and precise masking solution is clear.

Enhanced Masking Technology for Consistent Results

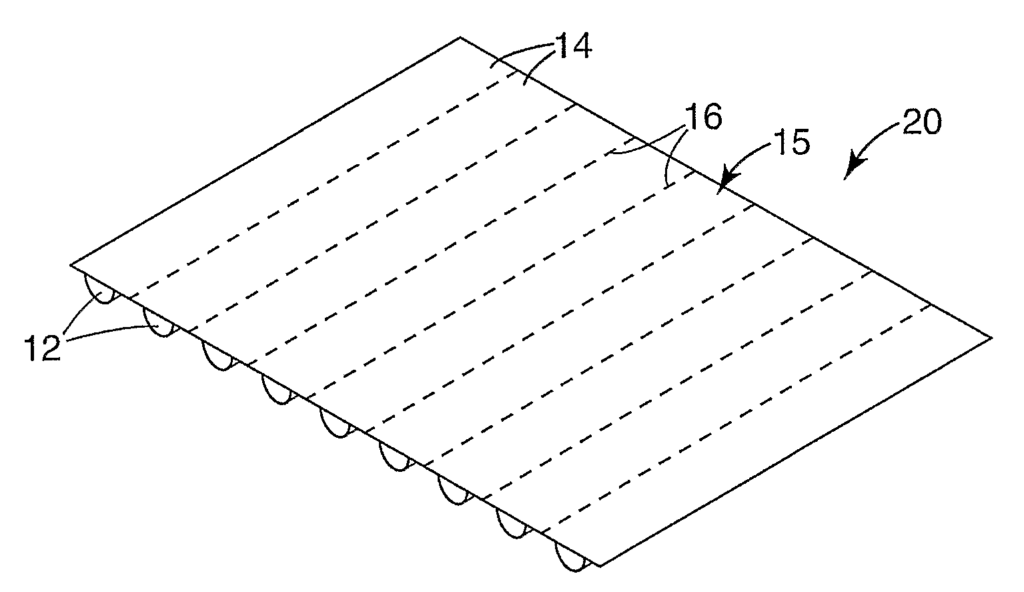

This masking technology provides a robust solution by offering superior adhesion and precise coverage, ensuring that surfaces remain protected throughout the painting or coating process. The article is designed to conform closely to the substrate, reducing the risk of overspray or misalignment. Its advanced adhesive properties allow for secure attachment while still being easy to remove, preventing damage to the underlying surface. This method significantly improves the accuracy of masking, leading to cleaner edges, reduced contamination, and a higher-quality final product.

Key Benefits for Industrial and Manufacturing Sectors

In the automotive industry, where high-precision painting and coating are essential, this masking technology ensures flawless surface protection, reducing the need for touch-ups and rework. Manufacturing companies benefit from enhanced efficiency, as the easy application and removal process streamline operations and cut down on time-consuming manual labor. For industrial painting and coating companies, this technology offers the durability and reliability needed to mask large areas or complex geometries, ensuring consistent results across a wide range of surfaces. Construction firms can also use this technology to protect substrates during painting or finishing tasks, preventing costly damage.

Invest in Precision and Productivity

Licensing this precision masking technology gives your organization a competitive edge in achieving superior surface protection with reduced waste and increased efficiency. By offering a masking solution that is easy to apply, conforms to various surfaces, and delivers clean results, your company can meet the demands of industries that prioritize high-quality finishes. This technology allows for greater control over the masking process, improving both the quality of the finished product and the speed of operations. It’s a smart investment for companies looking to elevate their surface protection methods and deliver flawless results in a variety of industrial applications.

- Abstract

- Claims

Share

Title

Masking article and method of masking of substrate

Inventor(s)

Kevin M. Eliason, Jeffrey R. Janssen, Larry R. Lappi, Larry A. Meixner, Michael J. Moszer

Assignee(s)

3M Innovative Properties Co

Patent #

8399058

Patent Date

March 19, 2013