Enhanced Wound Healing with a Lattice Dressing

Introduction

This innovative lattice dressing technology offers a superior solution for wound care by providing structured yet breathable support to enhance healing. Its unique lattice design allows for optimal moisture retention, ensuring that wounds remain hydrated while also protecting them from external contaminants. The dressing creates an ideal environment for tissue regeneration and wound closure, making it an essential tool for healthcare providers managing a wide range of wounds, from post-surgical to chronic injuries. For companies in the wound care industry, this technology represents a significant advancement in patient-centered care.

The Challenge: Achieving Optimal Wound Healing Conditions

Wound healing is a complex process that requires a delicate balance of moisture, protection, and breathability. Traditional wound dressings often fail to provide the necessary structure to keep wounds moist and protected while allowing the skin to breathe. This can lead to delayed healing, increased risk of infection, or excessive dryness that inhibits tissue regeneration. Healthcare providers need wound care solutions that effectively balance these factors to promote faster recovery and reduce complications for patients.

Lattice Dressing for Better Healing Outcomes

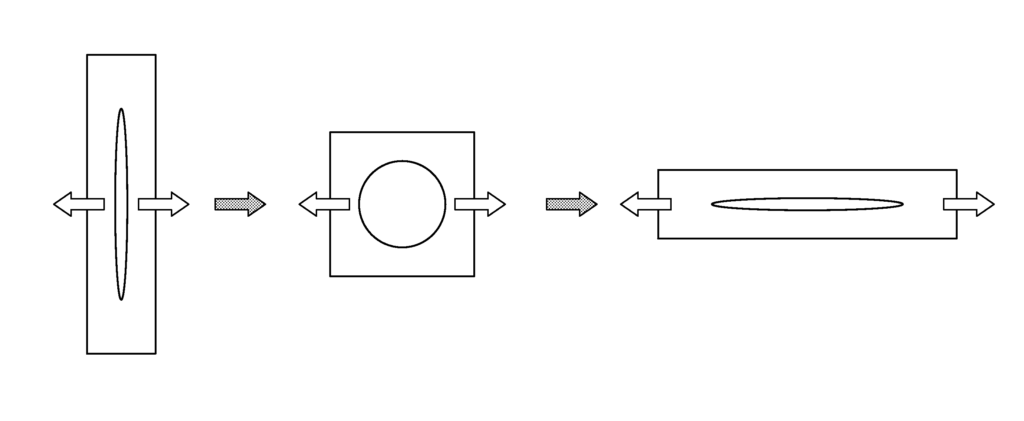

This lattice dressing technology addresses the challenges of traditional dressings by offering a structure that promotes better moisture management and protection. The breathable lattice design allows for optimal airflow while retaining the moisture necessary for proper healing. This structure not only supports tissue growth but also reduces the risk of infection by protecting the wound from harmful external agents. The dressing’s unique design makes it adaptable for various wound types, including surgical wounds, ulcers, and other complex injuries, offering a versatile and reliable solution for healthcare providers.

Key Benefits for Wound Care Providers and Manufacturers

For wound care product manufacturers, this lattice dressing provides an opportunity to introduce a cutting-edge solution that improves healing outcomes. Healthcare providers, including hospitals, clinics, and wound care specialists, can integrate this dressing into their wound management protocols to offer patients faster recovery times and enhanced protection. The dressing is particularly effective for patients with chronic or hard-to-heal wounds, providing the structured support needed for optimal healing. Its versatility makes it a valuable tool across various medical and surgical settings.

Invest in Innovative Wound Healing Technology

Licensing this lattice dressing for wound healing technology positions your company as a leader in the development of advanced wound care solutions. By offering a dressing that enhances moisture retention, supports tissue regeneration, and protects against infection, your business can meet the growing demand for innovative, patient-friendly wound care products. This technology provides a smart investment for companies focused on improving patient outcomes and delivering high-performance medical solutions.

- Abstract

- Claims

What is claimed is:

1. A wound dressing comprising:

an open lattice comprising:

10. A method of promoting the closure of a wound, comprising:

18. A wound dressing comprising:

a material comprising:

wherein:

22. A method of manufacturing a wound dressing comprising:

forming a plurality of slits in a material to form the wound dressing of claim 1 having an aperture pattern, wherein:

28. A wound dressing comprising:

a material comprising:

a film coupled with the material when the material is in the expanded conformation;

29. The wound dressing of claim 28, wherein:

Share

Title

Lattice dressing

Inventor(s)

Bryan Greener, Allan Freedline

Assignee(s)

Smith and Nephew Inc

Patent #

8680360

Patent Date

March 25, 2014