Light Up the Future with Revolutionary Single-Layer LEDs

Introduction

Step into the future of illumination with our patented “Single-Layer Light-Emitting Diodes Using Organometallic Halide Perovskite/Ionic-Conducting Polymer Composite” (Patent #10903441). This groundbreaking technology redefines what’s possible in the world of LEDs, combining cutting-edge materials with a streamlined design for unparalleled performance.

The Innovation

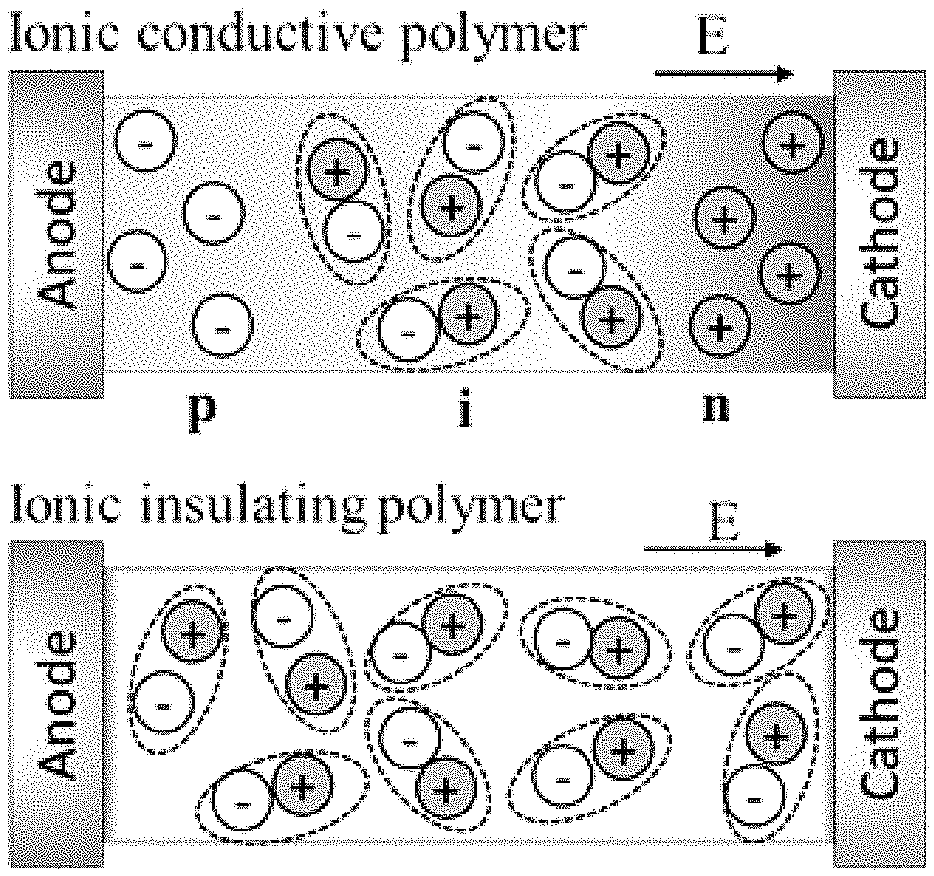

Imagine LEDs that are not only brighter and more efficient but also simpler to manufacture. Our single-layer design integrates advanced organometallic halide perovskites with ionic-conducting polymers, creating a composite that delivers high luminosity, low energy consumption, and exceptional durability—all in a single layer.

Why This Technology is a Game-Changer

- Simplicity Meets Efficiency: By eliminating the need for multiple layers, our LEDs offer a more straightforward manufacturing process, reducing costs and complexity while enhancing reliability.

- Brilliant Performance: These LEDs provide superior brightness and color purity, making them ideal for displays, lighting, and beyond—where vivid, energy-efficient illumination is essential.

- Versatile Applications: From consumer electronics to smart lighting and flexible displays, this technology is poised to revolutionize multiple industries with its versatility and efficiency.

The Opportunity

Don’t just adapt to the future—shape it. License this patent and bring to market the next generation of LEDs that offer simplicity, efficiency, and brilliance in one elegant solution. Illuminate the possibilities with technology that’s a step ahead.

- Abstract

- Claims

What is claimed is:

1. A single layer thin film optoelectronic device, comprising:

5. A single layer thin film optoelectronic device, comprising:

13. A single layer thin film optoelectronic device, comprising:

Share

Title

Single-layer light-emitting diodes using organometallic halide perovskite/ionic-conducting polymer composite

Inventor(s)

Zhibin Yu, Junqiang Li, Sri Ganesh Rohit Bade

Assignee(s)

Florida State University Research Foundation Inc

Patent #

10903441

Patent Date

January 26, 2021