Optimizing Plant Growth with Spectral Deficiency Automation

Introduction

As global demand for food continues to grow, agricultural industries are under increasing pressure to improve the efficiency and yield of their production systems. Traditional farming practices often lack the precision required to maximize plant growth, especially in controlled environments like greenhouses, vertical farms, and indoor growing systems. Our patented spectral deficiency-driven control system offers a smart, automated solution designed to optimize plant growth by precisely managing the light spectrum based on the specific needs of crops. This innovative technology allows growers to fine-tune lighting conditions, ensuring plants receive the exact wavelengths necessary for each stage of growth, resulting in higher yields and improved resource efficiency.

Challenges in Current Plant Growth Automation

In controlled environment agriculture (CEA) settings, such as greenhouses and vertical farms, lighting plays a critical role in plant development. However, traditional lighting systems often fail to adjust to the evolving needs of plants throughout their growth cycle. Plants require different wavelengths of light at different stages of growth—such as red light for flowering and blue light for vegetative growth. When these needs are not met, plants may experience reduced growth rates, lower yields, and suboptimal quality.

Furthermore, manual adjustments to lighting systems can be time-consuming and imprecise, leading to wasted energy and unnecessary operational costs. For growers looking to maximize efficiency and yield, there is a growing demand for intelligent automation solutions that can respond dynamically to plant growth conditions.

An Intelligent Solution for Precise Plant Lighting

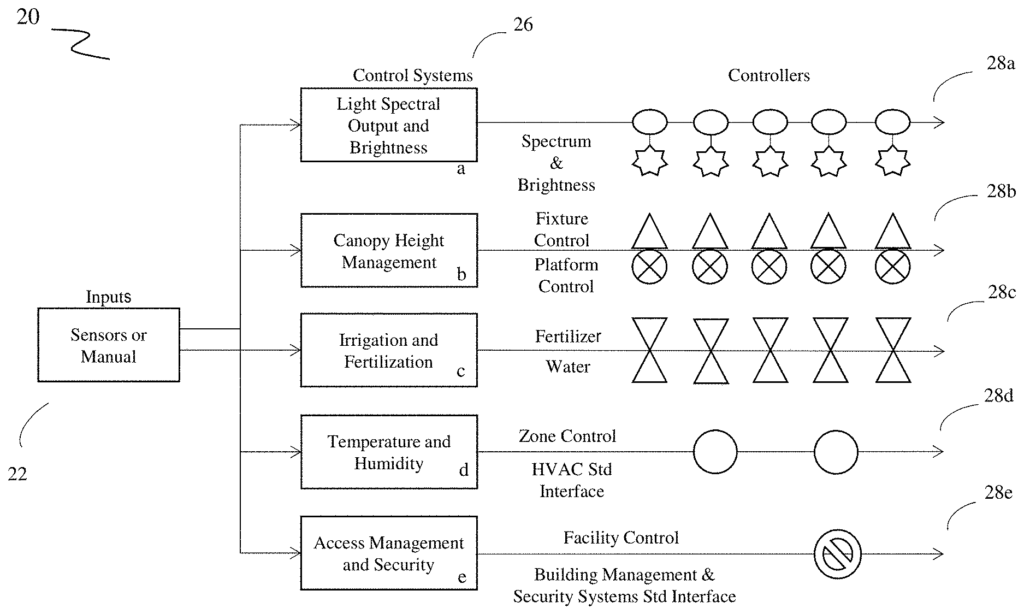

Our patented spectral deficiency-driven control system is designed to monitor the specific lighting needs of plants and automatically adjust the spectrum to optimize growth. Using real-time data and intelligent algorithms, the system identifies deficiencies in the light spectrum and compensates by delivering the precise wavelengths plants require at each stage of their life cycle. This ensures that plants receive the optimal amount and type of light, improving growth rates, yield, and quality.

The system is fully automated, allowing growers to focus on other aspects of plant care while ensuring that lighting is always optimized for maximum productivity. By minimizing the manual adjustments needed for lighting systems, the technology also reduces energy consumption and lowers operational costs, making it an eco-friendly and cost-effective solution for both small and large-scale farming operations.

Key Benefits

- Precision Light Spectrum Control: Automatically adjusts the light spectrum to match the specific needs of plants, promoting optimal growth at each stage.

- Increased Yield and Quality: Ensures plants receive the ideal light for improved growth rates, leading to higher yields and better-quality crops.

- Energy Efficiency: Reduces energy waste by delivering only the necessary light wavelengths, lowering operational costs.

- Automation for Scalability: Ideal for greenhouses, vertical farms, and other controlled environment agricultural systems, streamlining operations and maximizing efficiency.

Elevating Smart Farming with Automated Light Control

Licensing this spectral deficiency-driven control system provides agricultural technology companies and growers with a powerful tool to enhance plant growth, reduce costs, and improve overall productivity. This technology offers a scalable solution for smart farming operations that want to optimize their use of resources while delivering superior plant yields and quality.

- Abstract

- Claims

I claim:

1. A spectral deficiency-driven control system in a plant growth automation, said system comprising:

wherein the control system is further configured to:

15. The system of claim 1,

18. The system of claim 1, wherein

19. A spectral deficiency-driven control system in a plant growth automation, said system comprising:

at least one sensor configured to detect any number of segments of a light spectrum of at least one of facility-incoming and facility-generated light;

21. A spectral deficiency-driven control device in a plant growth automation, said device comprising:

wherein the device is further configured to:

29. A spectral deficiency-driven method, said method comprising the steps of:

Share

Title

Spectral deficiency driven control systems and methods in plant growth automation

Inventor(s)

Sam Lee

Assignee(s)

Infinity Capital LLC

Patent #

10517226

Patent Date

December 31, 2019