Reliable Electronics for Negative Pressure Wound Care

Introduction

This innovative technology provides robust protection for electronic components used in negative pressure wound therapy (NPWT) systems, ensuring their functionality and safety during treatment. NPWT is a critical wound care method, particularly for chronic or complex wounds, but the exposure of delicate electronics to fluids and contaminants poses a significant risk to the device’s longevity and effectiveness. For companies in the medical device industry, this technology offers a solution that increases the durability of NPWT systems, enhancing performance and ensuring consistent therapeutic outcomes for patients.

The Challenge: Protecting Electronics in Challenging Environments

Negative pressure wound therapy systems rely on sophisticated electronic components to regulate the pressure applied to wounds, which in turn promotes faster healing and tissue regeneration. However, the environment in which these devices operate—often involving exposure to bodily fluids, moisture, and contaminants—can compromise the integrity of the electronics. This may lead to device failure, inconsistent pressure regulation, and increased risks for patients. The challenge lies in protecting these sensitive electronics without affecting the overall functionality or effectiveness of the NPWT system.

Advanced Protection for Optimal Wound Care

This technology offers a comprehensive solution to protect the electronic components in NPWT systems from fluid exposure and contaminants. By creating a barrier that shields the electronics while maintaining system functionality, this technology ensures that NPWT devices operate reliably and safely, even in the harsh environments of wound care. The enhanced protection increases the longevity of the devices, reduces the risk of failure during treatment, and improves patient outcomes by providing consistent and controlled therapy. This innovation is crucial for maintaining the integrity of NPWT systems and ensuring that patients receive the highest quality care.

Key Benefits for Medical Device Manufacturers and Healthcare Providers

For medical device manufacturers, this technology provides a competitive advantage by ensuring that NPWT systems deliver reliable, long-term performance in challenging environments. Healthcare providers, including hospitals and wound care clinics, will benefit from using systems that are more durable and less prone to malfunction, leading to better patient outcomes and fewer device replacements or repairs. The added protection also reduces the overall costs associated with maintaining and replacing NPWT devices, making it an attractive option for both manufacturers and healthcare facilities.

Invest in Advanced Wound Care Solutions

Licensing this electronics protection technology for NPWT systems positions your company as a leader in the development of reliable, high-performance wound care devices. By ensuring the longevity and safety of electronic components in NPWT systems, your business can meet the growing demand for innovative, durable solutions in wound care. This technology represents a valuable investment for companies dedicated to improving patient outcomes and delivering advanced healthcare solutions.

- Abstract

- Claims

What is claimed:

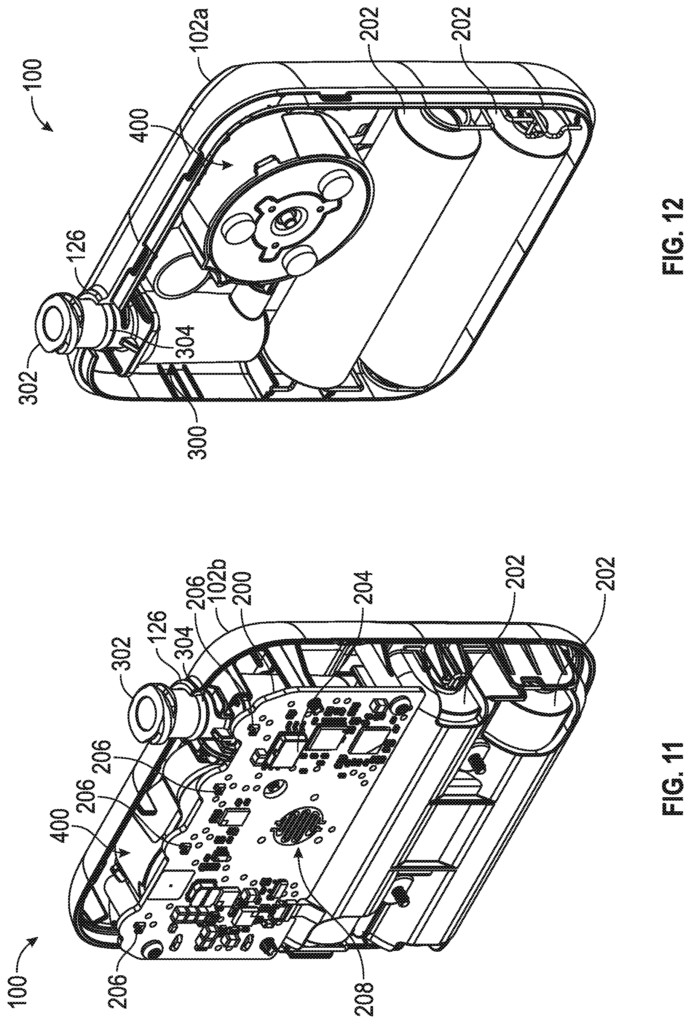

1. An apparatus for applying negative pressure to a wound, the apparatus comprising:

15. A method for operating a negative pressure wound therapy apparatus, the method comprising:

17. The method of claim 15,

Share

Title

Protection of electronics in negative pressure wound therapy systems

Inventor(s)

Ben Alan Askem, Fernando Bettani, Alberto Fasan, Allan Kenneth Frazer Grugeon Hunt, Felix Clarence Quintanar

Assignee(s)

Smith and Nephew PLC

Patent #

11511021

Patent Date

November 29, 2022