Sustainable Carbon Nano-Fibers

Introduction

In an era where sustainability meets cutting-edge material science, the ability to produce high-performance carbonaceous nano-fibrous materials from renewable sources is a game-changing innovation. Our patented process for producing carbon nano-fibers from Kraft lignin offers a solution that combines environmental responsibility with exceptional material performance. With ultra-high specific surface areas, these carbon nano-fibers open up possibilities across multiple industries, including energy storage, filtration, and advanced manufacturing.

Current Barriers in Carbon Material Production

Carbon nano-fibers are known for their impressive mechanical, thermal, and electrical properties, making them highly desirable for use in a wide range of applications, from electronics to energy storage. However, the production of these materials often relies on non-renewable resources like petroleum, leading to environmental concerns and higher costs. Additionally, conventional processes for producing nano-fibers are often complex, expensive, and inefficient, limiting their scalability and commercial viability.

The growing demand for sustainable materials, coupled with the need for more efficient, cost-effective manufacturing processes, presents a significant challenge for industries that depend on high-performance carbon materials.

Why Choose Sustainable Carbon Nano-Fibers?

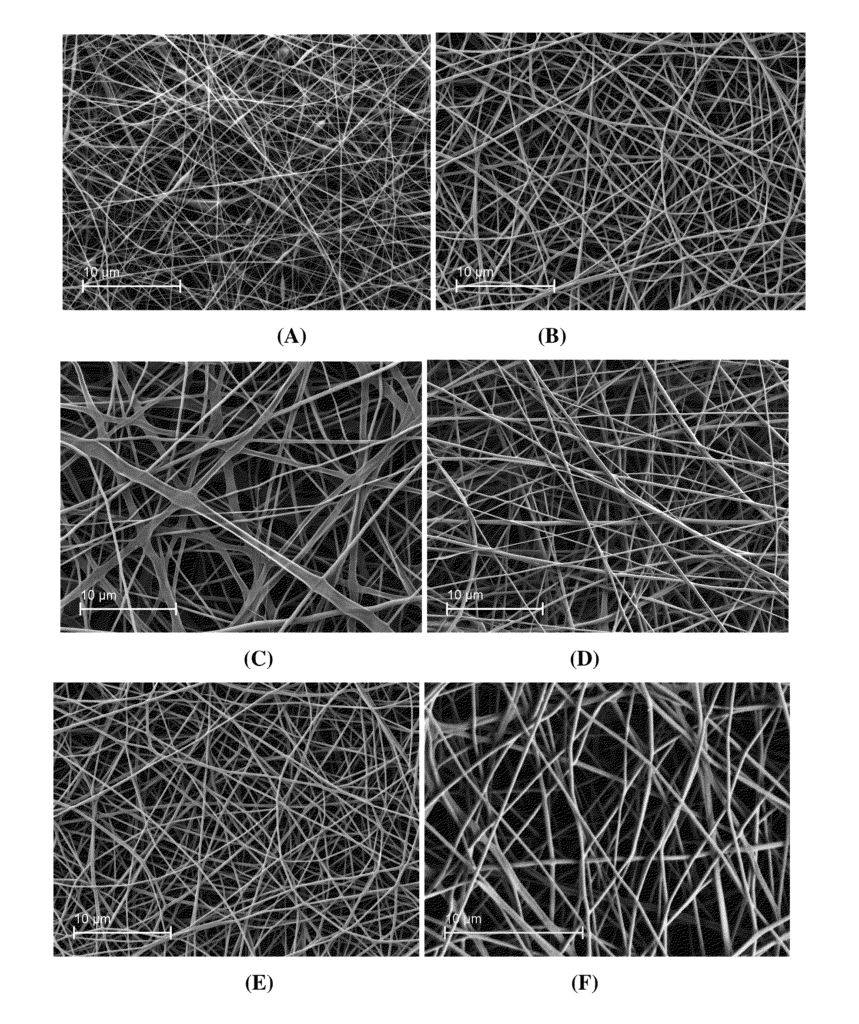

Our patented method offers a transformative approach to producing carbon nano-fibers using alkali (Kraft) lignin, a renewable byproduct from the paper industry. This process not only provides a sustainable alternative to traditional carbon sources but also yields materials with ultra-high specific surface areas, making them ideal for high-performance applications like energy storage, filtration, and advanced composites.

The use of lignin in the production of carbon nano-fibers significantly reduces the reliance on non-renewable resources and lowers production costs, making it an eco-friendly and commercially viable solution. The resulting nano-fibrous materials exhibit superior mechanical strength, electrical conductivity, and thermal stability, positioning them as a superior choice for a variety of industrial uses.

Key Benefits

- Sustainable Production: Utilizes renewable lignin, reducing the environmental footprint of carbon material production.

- Ultra-High Surface Area: Offers exceptional performance in energy storage devices, filters, and other applications.

- Cost-Effective: Lowers production costs compared to traditional carbon nano-fiber manufacturing methods.

- Versatile Applications: Suitable for use in batteries, capacitors, filtration systems, and advanced composites.

Drive Innovation with Sustainable Carbon Nano-Fibers

Licensing this sustainable carbon nano-fiber technology provides companies in energy storage, advanced materials, and environmental engineering with a powerful tool for creating high-performance, eco-friendly products. With its superior material properties and sustainable production process, this innovation offers a clear path forward for industries committed to both performance and sustainability.

- Abstract

- Claims

What is claimed is:

1. A method for the manufacture of carbon nanofibers comprising:

13. A method for preparing carbon nanofibers comprising:

17. The method of claim 16, wherein said nanofibers

18. A method for preparing carbon nanofibers comprising

Share

Title

Production of carbonaceous nano-fibrous materials with ultra-high specific surface area from alkali (Kraft) lignin

Inventor(s)

Lifeng Zhang, Ajit Kelkar, Hao Fong, Chuilin Lai

Assignee(s)

North Carolina A&T State University, South Dakota School of Mines and Technology

Patent #

9190222

Patent Date

November 17, 2015